Slurry circulating system and method of workover rig

A circulation system and workover rig technology, applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve problems such as high difficulty in relocation and installation, insufficiently compact structure, large footprint, etc., and achieve performance adjustment And the effect of convenient and fast regulation, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

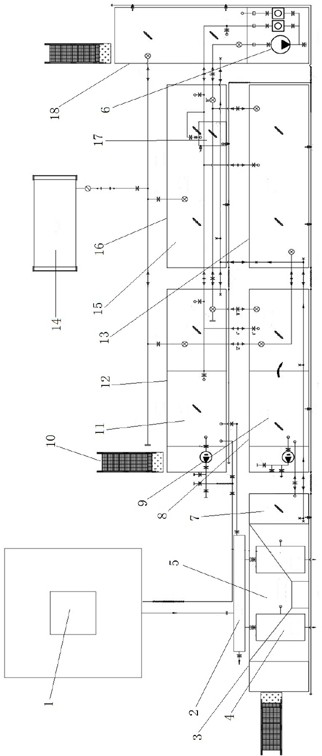

[0043] As a preferred embodiment of the present invention, this embodiment provides a mud circulation system for a workover rig, including six circulation tanks, a weight pump 6, a mud pump 14, an output pipe network and a suction pipe network, and the six circulation tanks They are No. 1 tank 3, No. 2 tank 8, No. 3 tank 13, No. 4 tank 12, No. 5 tank 16 and No. 6 tank 18. The No. 1 tank 3 is equipped with vibrating screen 4, grit chamber and degassing tank. Tank 7 and No. 2 tank 8 are provided with a gravity settling bin and an upper water bin 15, No. 3 tank 13, No. 5 tank 16 and No. 6 tank 18 are each provided with a water upper bin 15, and No. 4 tank 12 is provided with a grouting bin 11 And the upper water bin 15, the mud pump 14 is connected with the upper water bin 15 in each circulation tank through the external pipeline, the grouting pump is arranged in the grout bin 11, the gravity sedimentation tank is arranged in the gravity sedimentation bin, and the circulation tank...

Embodiment 2

[0046] As another preferred embodiment of the present invention, refer to the attached figure 1 , this embodiment provides a mud circulation system for a workover rig, including six circulation tanks, a weight pump 6, a mud pump 14, an output pipe network and a suction pipe network, and the six circulation tanks are No. 1 tank 3, No. 2 tank respectively No. tank 8, No. 3 tank 13, No. 4 tank 12, No. 5 tank 16 and No. 6 tank 18, the No. 1 tank 3 is provided with a vibrating screen 4, a grit chamber and a degassing bin 7, and No. 2 tank 8 is provided with There are gravity settling bins and upper water bins 15, No. 3 tank 13, No. 5 tank 16 and No. 6 tank 18 are equipped with an upper water bin 15, and No. 4 tank 12 is equipped with a grouting bin 11 and an upper water bin 15, and a mud pump 14 is connected with the upper water bin 15 in each circulation tank through an external pipeline, a grouting pump is arranged in the grout bin 11, a gravity sedimentation tank is arranged in ...

Embodiment 3

[0049] As another preferred embodiment of the present invention, this embodiment provides a mud circulation system for a workover rig, including six circulation tanks, a weight pump 6, a mud pump 14, an output pipe network and a suction pipe network, the six The circulation tanks are No. 1 tank 3, No. 2 tank 8, No. 3 tank 13, No. 4 tank 12, No. 5 tank 16 and No. 6 tank 18. The No. 1 tank 3 is provided with a vibrating screen 4, a grit chamber and Degassing bin 7, No. 2 tank 8 are provided with gravity settling bin and upper water bin 15, No. 3 tank 13, No. 5 tank 16 and No. 6 tank 18 are each provided with a upper water bin 15, and No. 4 tank 12 is provided with grouting Bin 11 and upper water bin 15, mud pump 14 is connected with upper water bin 15 in each circulation tank through external pipelines, grouting pump is arranged in said grout bin 11, gravity settling tank is arranged in gravity sedimentation bin, and said circulation Interconnected suction pipes are arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com