Fixed angle constant pressure automatic compensation feeding device and compensation feeding method

An automatic compensation and feeding device technology, applied in the direction of grinding drive device, grinding machine tool parts, metal processing equipment, etc., can solve the problem that the control accuracy of blade size cannot reach high-precision grinding blade belt, and cannot be scaled and batched Production of high-precision sharp knife belts, high-precision grinding of difficult knife belts, etc., to achieve the effect of simple high-precision grinding, improved surface roughness level, and improved sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] According to the claims of the present invention and the contents disclosed in the summary of the invention, the technical solution of the present invention is specifically described as follows.

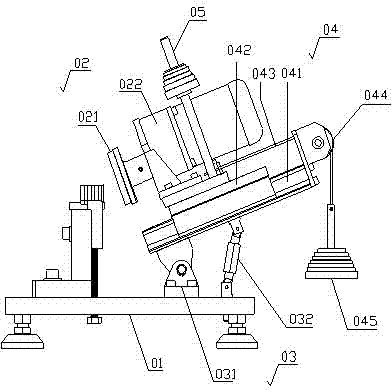

[0036] Please see attached figure 1 and attached figure 2 As shown, the fixed angle constant pressure automatic compensation feed device of the present invention includes: a base plate 01, a grinding assembly 02, an angle adjustment assembly 03 and a compensation feed assembly 04; the grinding assembly 02 is arranged above the base plate 01 through the angle adjustment assembly 03, and the grinding assembly 02 rotates in a vertical plane above the bottom plate 01; the compensating feed assembly 04 is arranged on the grinding assembly 02.

[0037] The grinding assembly 02 includes a grinding wheel 021 and a motor 022. The grinding wheel 021 is arranged on the shaft head of the motor 022 and rotates synchronously with the shaft head of the motor 022. The front end of the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com