Organic dye for fabric dyeing and preparation method thereof

An organic dye and fabric dyeing technology, applied in the field of textile dyeing, can solve the problems of narrow application range, easy fading and storage, difficulty, etc., and achieve the effect of good leveling effect, easy removal and elution, and less residual amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

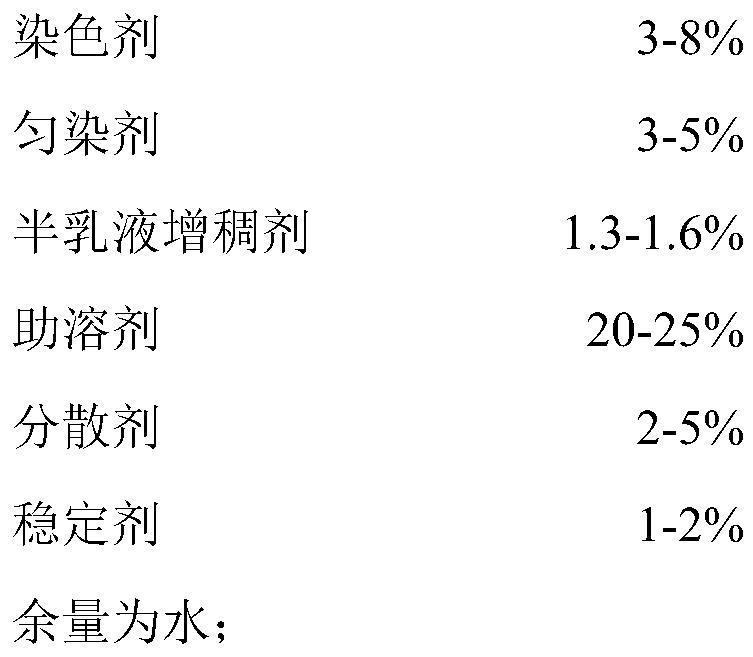

[0050] The concrete implementation parameter of embodiment 1-embodiment 6 is as shown in table 1, and wherein embodiment 1-embodiment 4 is the technical parameter that the present invention limits, does not contain stabilizer in embodiment 5, does not contain dispersant in embodiment 6 And stabilizer, wherein embodiment 5-embodiment 6 is comparative example.

[0051] The concrete implementation parameter of table 1 embodiment 1-embodiment 6

[0052]

[0053]

[0054] A kind of preparation method of the organic dyestuff that above-mentioned embodiment 1 is used for fabric dyeing, comprises the steps:

[0055] S1 Preparation of semi-emulsion thickener: prepare thickener and emulsifier according to the weight ratio, mix the two, heat up to 40°C, stir and mix for 30 minutes, put it in a closed container for use;

[0056] S2 Dye Grinding: Put the dye into a pulverizer and pulverize it to obtain a dye powder with a particle size ≥ 200 mesh;

[0057] S3 preparation of organic d...

Embodiment 2

[0060] A kind of preparation method of the organic dyestuff that above-mentioned embodiment 2 is used for fabric dyeing, comprises the steps:

[0061] S1 Preparation of semi-emulsion thickener: Prepare thickener and emulsifier according to the weight ratio, mix the two, heat up to 50°C, stir and mix for 20 minutes, put it in a closed container for use;

[0062] S2 Dye Grinding: Put the dye into a pulverizer and pulverize it to obtain a dye powder with a particle size ≥ 200 mesh;

[0063] S3 preparation of organic dyes: adding dyes, leveling agents, co-solvents, dispersants and water by weight percentage, heating up to 70°C and stirring for 45 minutes, then adding the semi-emulsion thickener in step S1 and stirring for 10 minutes, cooling to 25°C, Adjust the pH, add a stabilizer to dissolve evenly, and put the prepared organic dye into a dark airtight container.

[0064] Specifically, the pH in the step S3 is 5.0.

[0065] The shelf life of the organic dye prepared in Example...

Embodiment 3

[0066] A kind of preparation method of the organic dyestuff that above-mentioned embodiment 3 is used for fabric dyeing, comprises the steps:

[0067] S1 Preparation of semi-emulsion thickener: prepare thickener and emulsifier according to the weight ratio, mix the two, heat up to 45°C, stir and mix for 25min, put it in a closed container for use;

[0068] S2 Dye Grinding: Put the dye into a pulverizer and pulverize it to obtain a dye powder with a particle size ≥ 200 mesh;

[0069] S3 preparation of organic dyes: adding dyes, leveling agents, solubilizers, dispersants and water by weight percentage, heating up to 65°C and stirring for 50 minutes, then adding the semi-emulsion thickener in step S1 and stirring for 15 minutes, cooling to 20°C, Adjust the pH, add a stabilizer to dissolve evenly, and put the prepared organic dye into a dark airtight container.

[0070] Specifically, the pH in the step S3 is 6.0.

[0071] The shelf life of the organic dye prepared in Example 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com