SxCoOOH electrocatalyst, preparation method and application thereof

An electrocatalyst and sodium sulfide technology, which is applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of inability to meet industrial requirements and high price of precious metal catalysts, and achieve the effect of improving OER performance, simple composition, and good catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

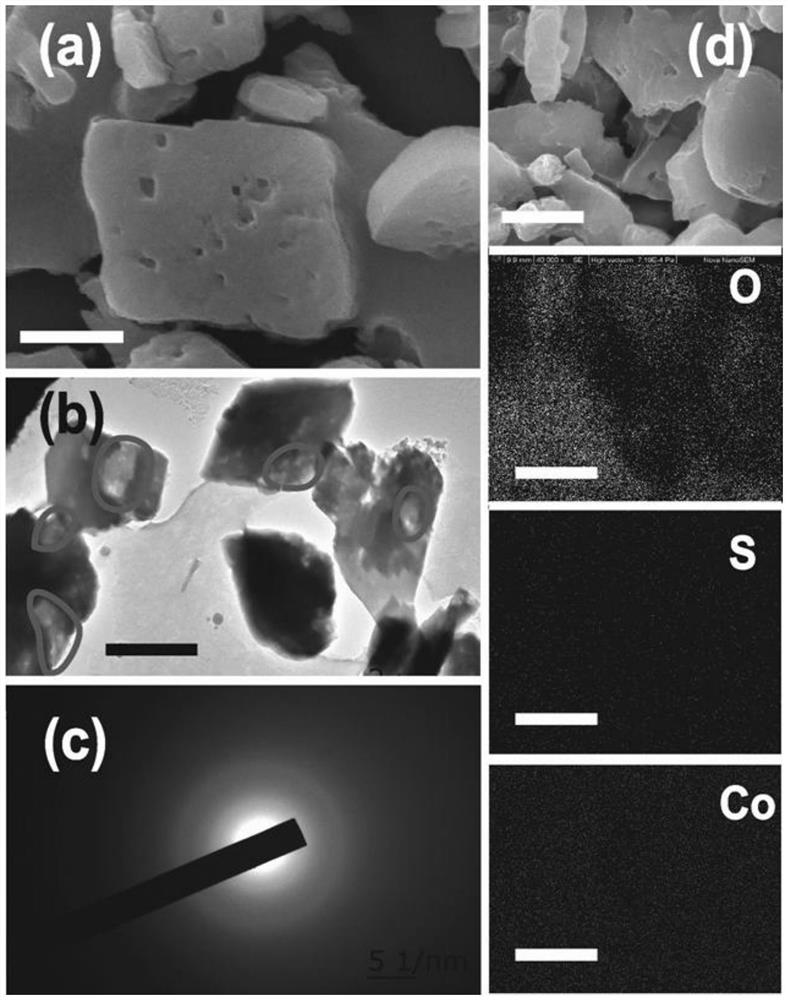

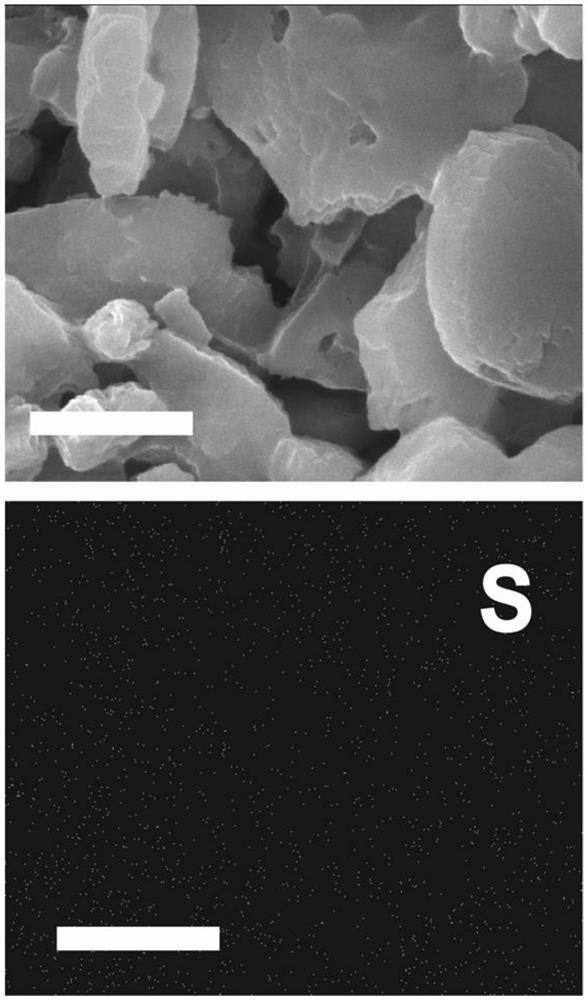

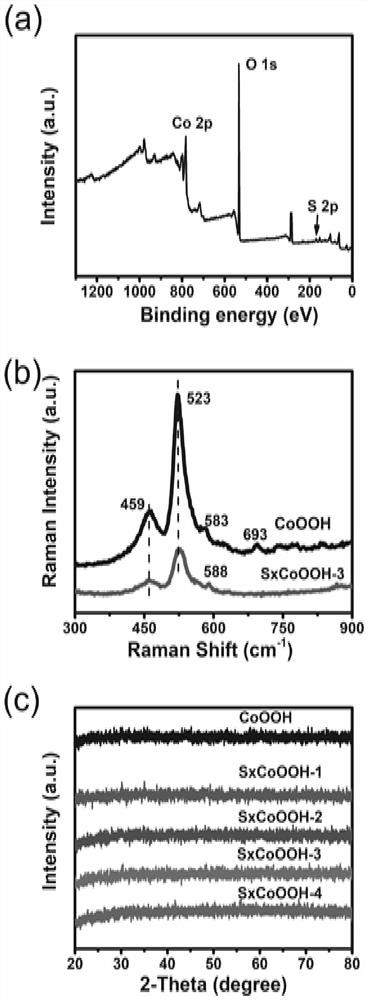

[0026] S x The specific preparation steps of CoOOH-1 are as follows:

[0027] Weigh 1.8mmol cobalt acetate, put 105mg ascorbic acid into a round bottom flask, add 95mL H 2O, stirred at 25°C for 30min, then slowly added dropwise a mixture of 100mg sodium hydroxide, 5mg sodium sulfide and 5mL H 2 Mixed solution A composed of O. (Since there is S in this mixed solution A 2- , which is easily absorbed by the O in the air 2 Oxidation must be prepared and used immediately, too early preparation may cause errors). Continue to stir for 30min, then slowly raise the temperature to 80°C, then keep stirring for 2h, collect the product, wash with absolute ethanol and H 2 The samples were obtained after O washing and drying.

Embodiment 2

[0029] S x The specific preparation steps of CoOOH-2 are as follows:

[0030] Weigh 1.8mmol cobalt acetate, put 105mg ascorbic acid into a round bottom flask, add 95mL H 2 O, stirred at 25°C for 30min, then slowly added dropwise a mixture of 100mg sodium hydroxide, 10mg sodium sulfide and 5mL H 2 Mixed solution A composed of O. (Since there is S in this mixed solution A 2- , which is easily absorbed by the O in the air 2 Oxidation must be prepared and used immediately, too early preparation may cause errors). Continue to stir for 30min, then slowly raise the temperature to 80°C, then keep stirring for 2h, collect the product, wash with absolute ethanol and H 2 The samples were obtained after O washing and drying.

Embodiment 3

[0032] S x The specific preparation steps of CoOOH-3 are as follows:

[0033] Weigh 1.8mmol cobalt acetate, put 105mg ascorbic acid into a round bottom flask, add 95mL H 2 O, stirred at 25°C for 30min, then slowly added dropwise a mixture of 100mg sodium hydroxide, 15mg sodium sulfide and 5mL H 2 Mixed solution A composed of O. (Since there is S in this mixed solution A 2- , which is easily absorbed by the O in the air 2 Oxidation must be prepared and used immediately, too early preparation may cause errors). Continue to stir for 30min, then slowly raise the temperature to 80°C, then keep stirring for 2h, collect the product, wash with absolute ethanol and H 2 The samples were obtained after O washing and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com