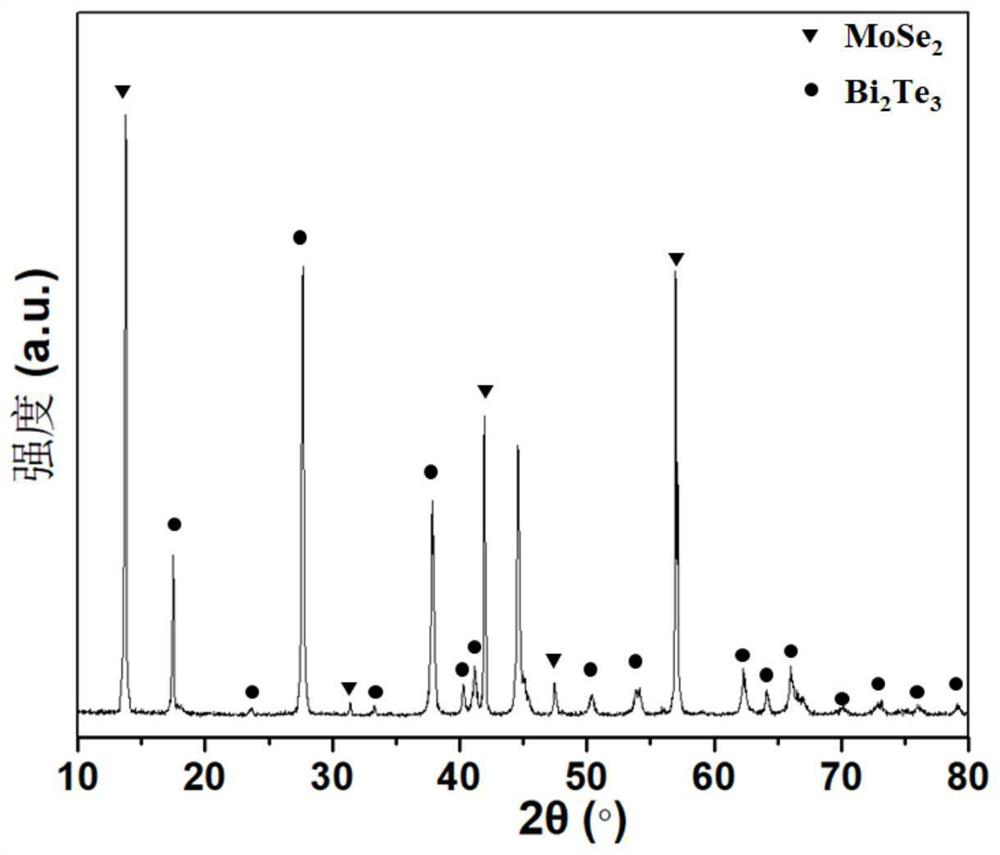

Bismuth telluride-molybdenum diselenide nanosheet as well as preparation method and application thereof

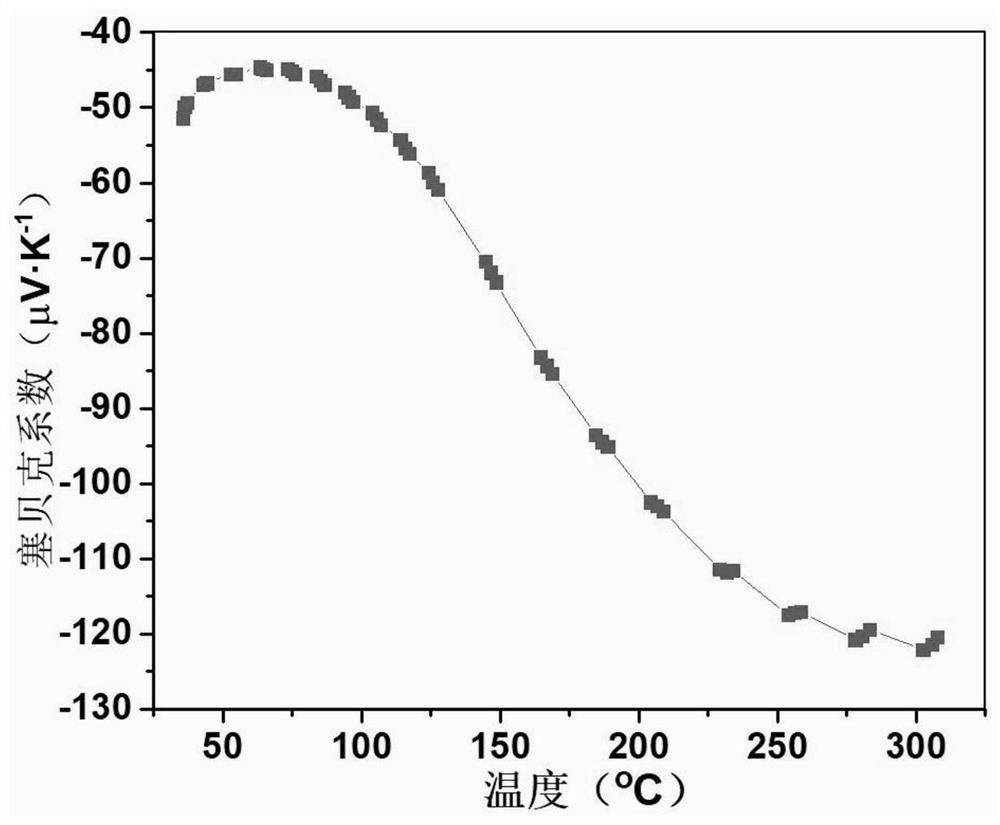

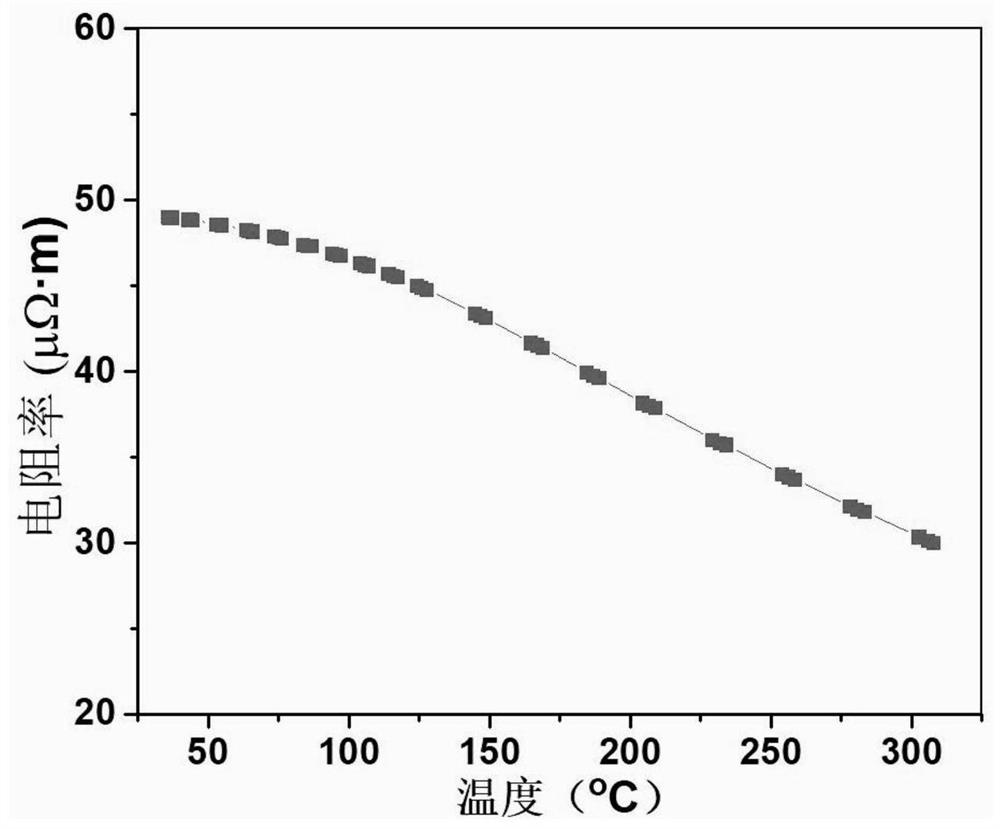

A technology of molybdenum diselenide and bismuth telluride, which is applied in nanotechnology, nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of poor thermoelectric performance and stability, and materials are easily oxidized, and achieve excellent thermoelectric performance, Reduce the overall concentration and mobility, improve the effect of phonon scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of bismuth telluride-molybdenum diselenide nanosheets, comprising the following steps:

[0046] 1) Dissolve 0.96g of sodium molybdate dihydrate in 50mL of deionized water, and stir until completely dissolved to obtain a sodium molybdate solution;

[0047] 2) Add 2.0g of bismuth telluride and 0.85g of selenium dioxide into the sodium molybdate solution in step 1), fully stir for 5 minutes, then add 2.7g of sodium sulfite as a reducing agent, and fully stir for 5 minutes to obtain a precursor solution. Transfer the precursor solution to a 100mL polytetrafluoroethylene hydrothermal reactor;

[0048] 3) Put the polytetrafluoroethylene hydrothermal reaction kettle at 200°C for 24 hours, cool it down to room temperature naturally after the reaction, wash it with deionized water three times and dry it at 60°C to obtain a solid; put the solid into the tube In a type furnace, calcined at 300°C for 1 h in a nitrogen atmosphere, and cooled to obtain bismuth t...

Embodiment 2

[0055] Compared with Example 1, the main difference is that powdered selenium is used as the selenium source, and potassium molybdate is used as the molybdenum source.

[0056] A preparation method of bismuth telluride-molybdenum diselenide nanosheets, comprising the following steps:

[0057] 1) Dissolve 1.37g potassium molybdate in 50mL deionized water, stir until completely dissolved to obtain potassium molybdate solution;

[0058]2) Add 2.0g of bismuth telluride and 0.75g of selenium powder into the potassium molybdate solution in step 1), fully stir for 5 minutes, then add 1.3g of sodium sulfite as a reducing agent, and fully stir for 5 minutes to obtain a precursor solution. The precursor solution was transferred to a 100mL polytetrafluoroethylene hydrothermal reactor;

[0059] 3) Put the polytetrafluoroethylene hydrothermal reaction kettle at 200°C for 24 hours, cool it down to room temperature naturally after the reaction, wash it with deionized water three times and d...

Embodiment 3

[0062] Compared with Example 1, the main difference is that hydrazine hydrate is used as reducing agent.

[0063] A preparation method of bismuth telluride-molybdenum diselenide nanosheets, comprising the following steps:

[0064] 1) Dissolve 0.96g of sodium molybdate dihydrate in 50mL of deionized water, and stir until completely dissolved to obtain a sodium molybdate solution;

[0065] 2) Add 2.0g of bismuth telluride and 0.85g of selenium dioxide into the sodium molybdate solution in step 1), fully stir for 5 minutes, then add 15mL of hydrazine hydrate as a reducing agent, and fully stir for 5 minutes to obtain a precursor solution. Transfer the precursor solution to a 100mL polytetrafluoroethylene hydrothermal reactor;

[0066] 3) Put the polytetrafluoroethylene hydrothermal reaction kettle at 200°C for 24 hours, cool it down to room temperature naturally after the reaction, wash it with deionized water three times and dry it at 60°C to obtain a solid; put the solid into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com