Automatic machining device for parts of wind power generation hydraulic equipment

A technology for hydraulic equipment and processing devices, applied in metal processing equipment, grinding/polishing equipment, grinding/polishing safety devices, etc. Improve stability, process stability, and ensure stable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

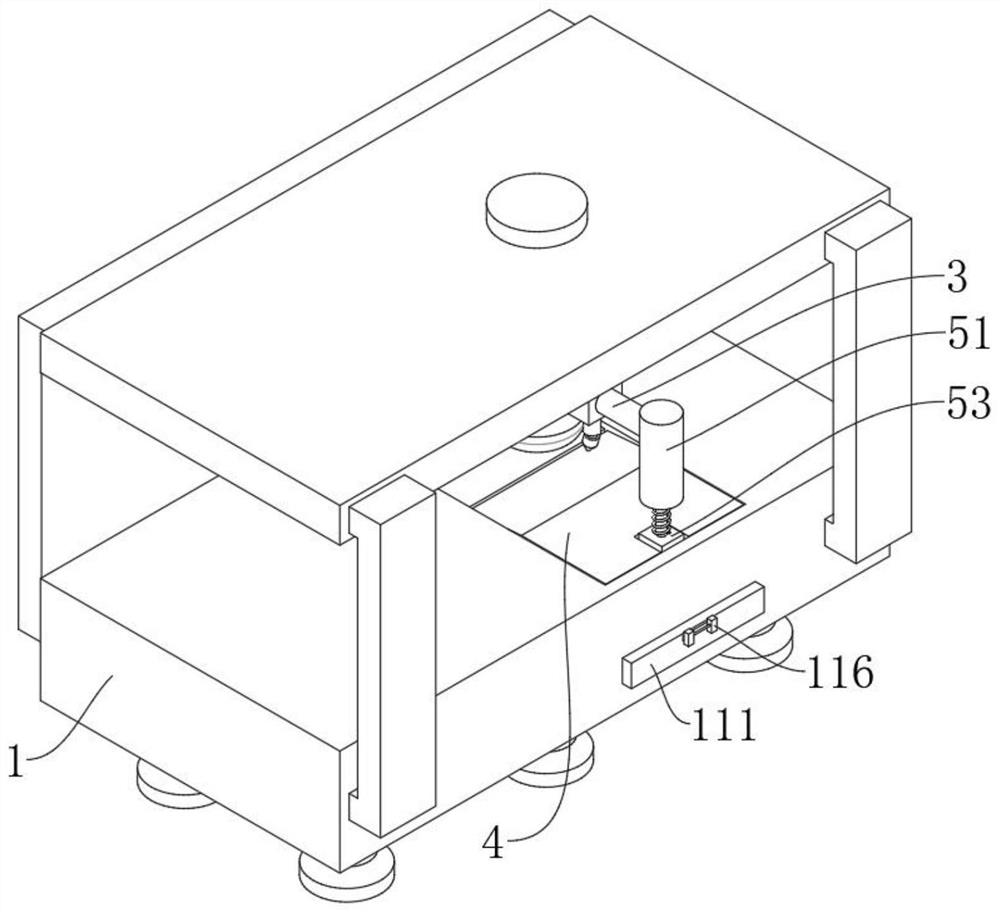

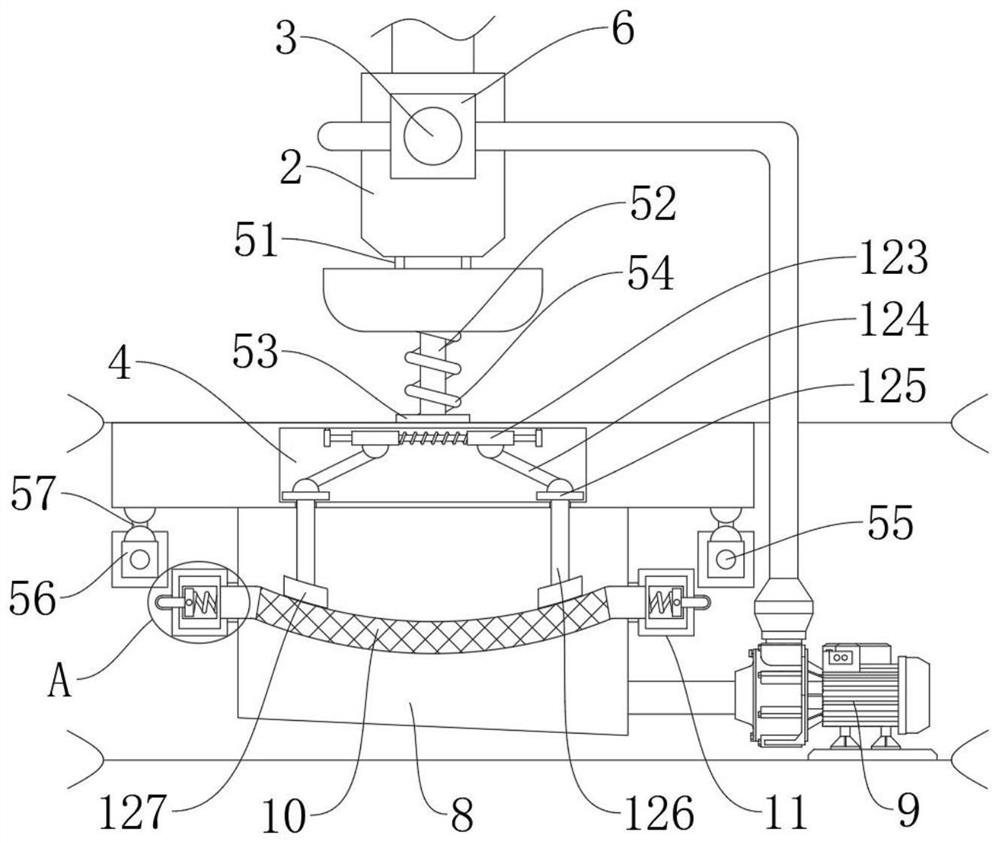

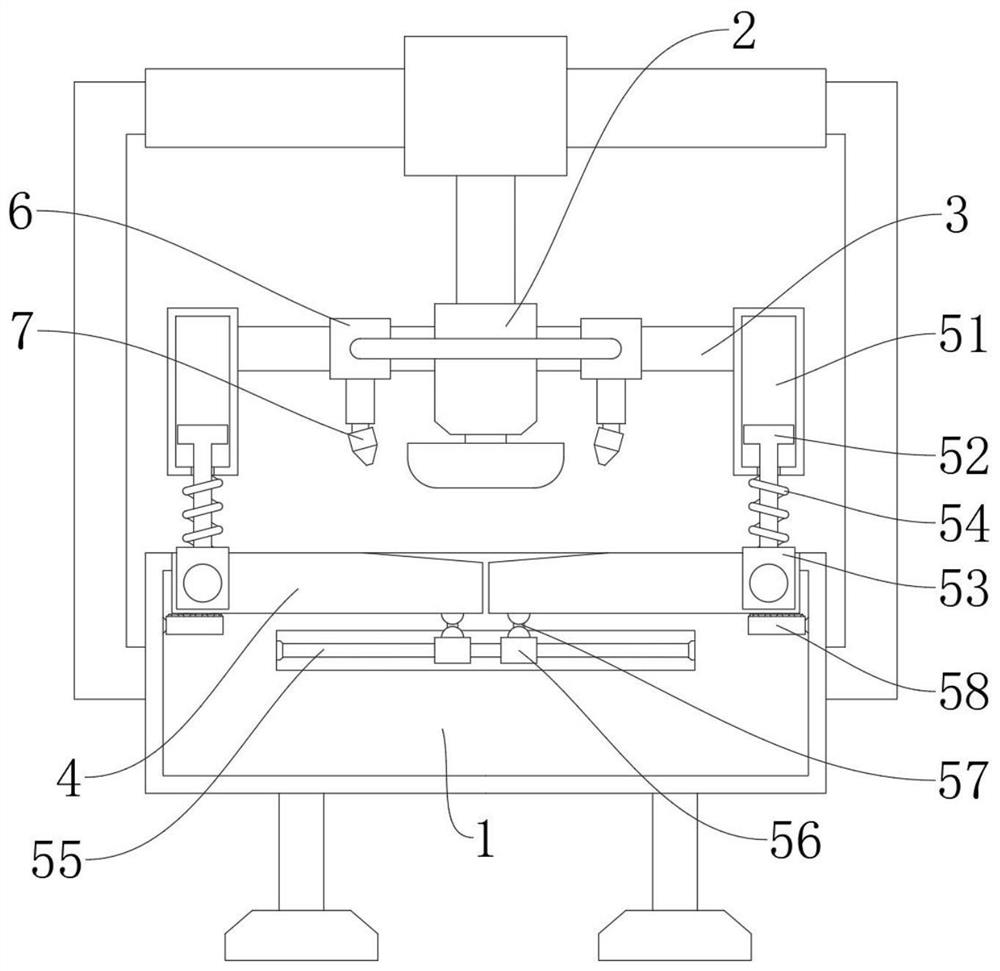

[0043] like Figure 1-Figure 7 As shown, an automatic processing device for wind power hydraulic equipment components includes a workbench 1, a top plate connected to the workbench 1 through a mounting plate, a control unit and a driving part arranged in the workbench 1, and a pusher arranged in the top board And the processing part 2 connected with the output end of the pusher, the two sides of the processing part 2 are fixedly installed with the fixed column 3, the worktable 1 is provided with the work plate 4, the fixed column 3 and the work plate 4 are connected through the connecting assembly 5 connection, a water tank 6 is installed in the fixed column 3, a nozzle 7 is connected to the bottom of the water tank 6, a collection cabin 8 is arranged inside the workbench 1, and a water pump 9 connected to the water tank 6 and the collection cabin 8 is arranged in the workbench 1 A filter plate 10 is inserted in the collection cabin 8, a dismounting assembly 11 for fixing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com