Closed dust removal room in molten metal pouring production line

A production line and molten metal technology, applied in the field of material forming and metal parts forming, can solve problems such as environmental pollution in workshops, and achieve the effect of ensuring no pollution and ensuring good health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

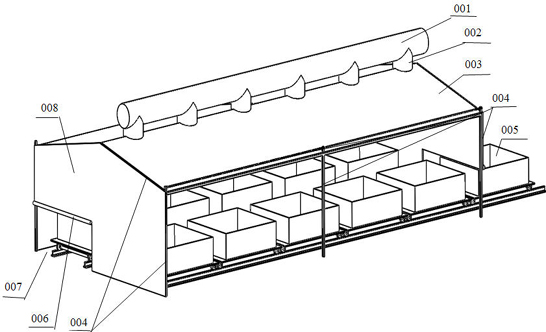

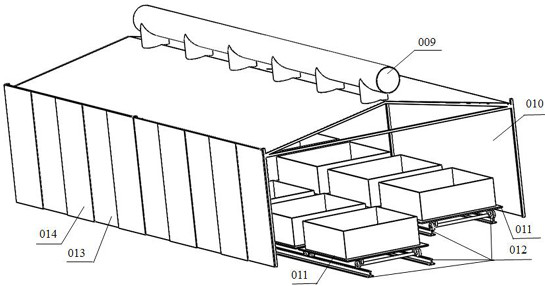

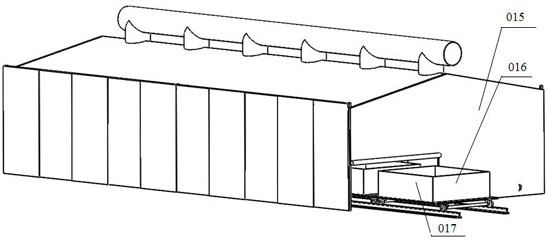

[0042] Our company's resin sand production workshop is all assembly line operations, with a production capacity of 3 tons per hour. The size of the sand box is 1350×1350×200 / 250, and the length of the dust removal room×width×height=15000×4500×2450. The interior design of the dust removal room is three For the track, the one close to the pouring side is used for pouring molten metal, and the two inside are used for heat preservation and cooling after pouring. The room frame 004 and column 022 of the dust removal room are all welded by 50×50 square steel, the roof 003 and rear wall panel 010 of the dust removal room, the inlet end wall panel 015, and the outlet end wall panel 008 are all made of 1mm steel plate and Closed, poured side door curtains, imported roller shutters 016 and outlet roller shutters 006 are made of flexible high-temperature-resistant fireproof cloth produced by outsourced professional factories. During normal pouring, only open the door curtain at the pouri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com