Extraction device for preparing ampelopsis grossedentata

An extraction device and technology for rattan tea, which are applied in the directions of cleaning methods using liquids, tea substitutes, solid solvent extraction, etc., can solve the problems of increasing the land area of the processing device, poor manufacturing processes, and viscosity of the water extract, etc. Improve convenience, improve usability, and speed up the effect of the entire process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

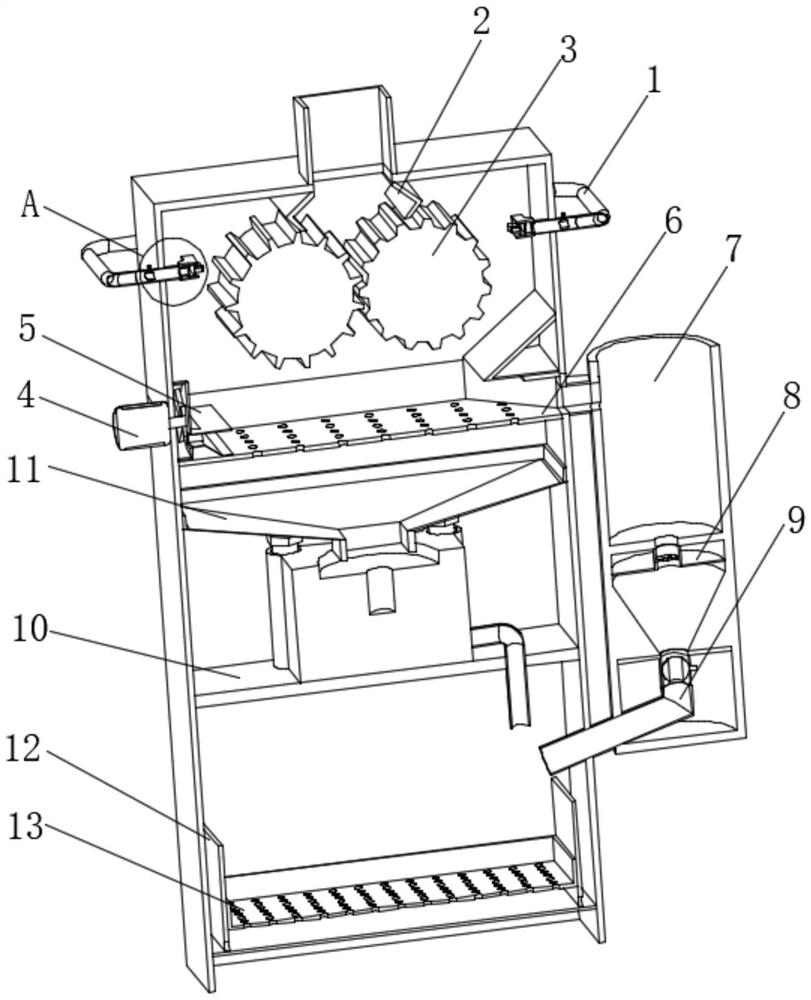

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

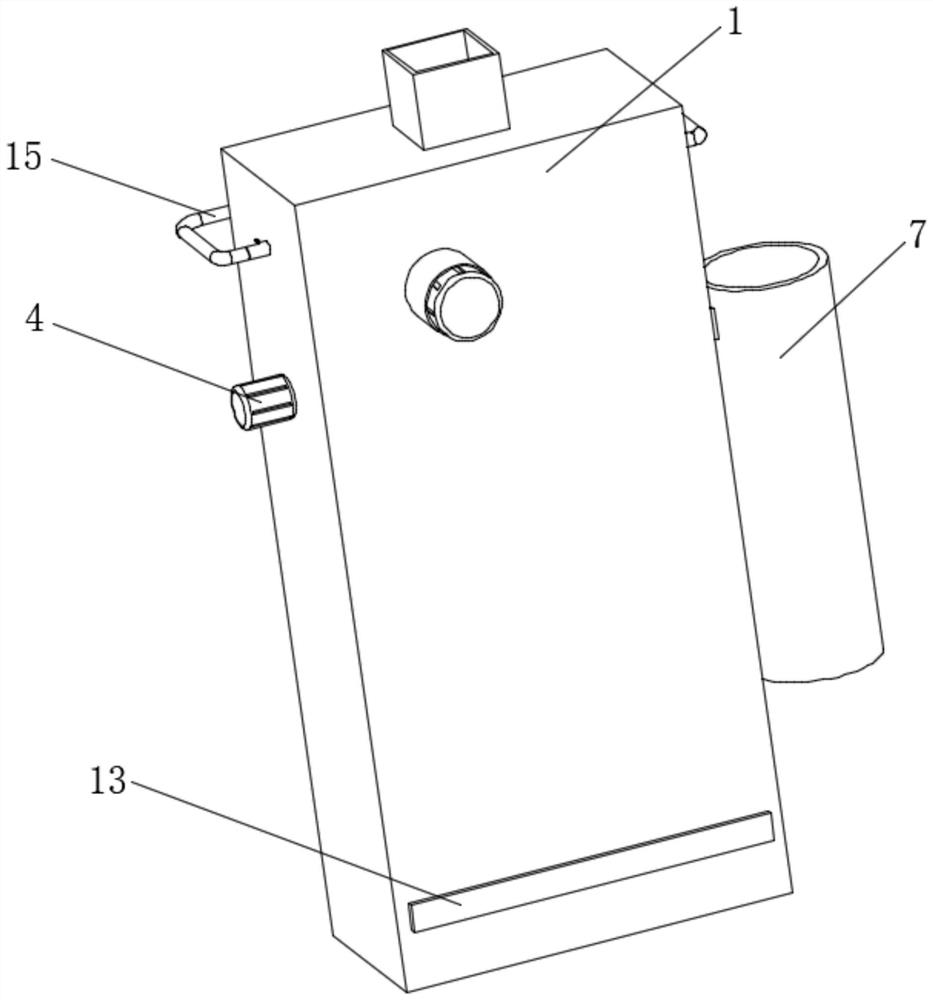

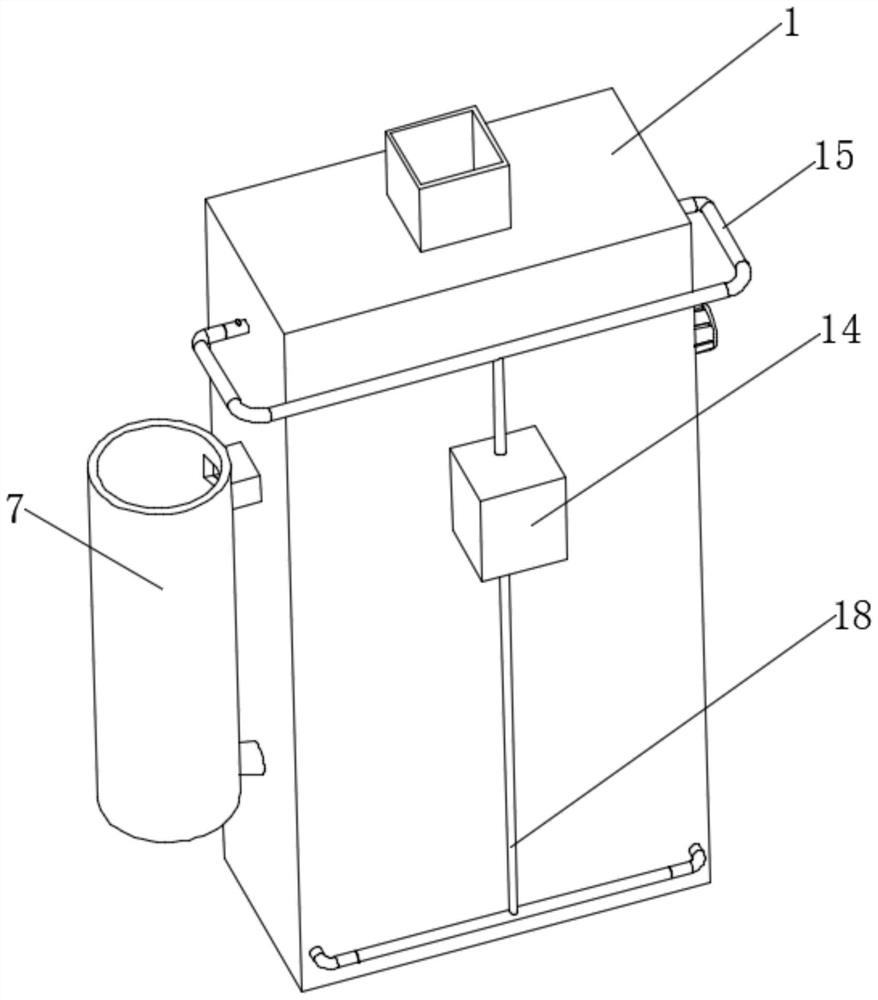

[0026] see Figure 1 to Figure 2 , the present invention provides a technical solution: an extracting device for preparing vine tea, comprising a main box 1, the main box 1 is the main body of the device, and the inside of it plays the role of a linkage stirring roller 3 and an extraction generator 7 As a result, the rough material of rattan tea can be directly transported to the inside of the extraction generator 7 for extraction, and the top of the inner cavity of the main box body 1 is fixedly connected with a baffle plate 2, and the baffle plate 2 plays the role of limiting the raw material of rattan tea. It avoids errors when the raw materials are put in, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com