Device and method for preparing polyaluminum chloride water purifying agent

A polyaluminum chloride and preparation device technology, applied to chemical instruments and methods, mixers, transportation and packaging, etc., can solve problems affecting mixing effects, affecting product quality, and clogging pores with materials, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

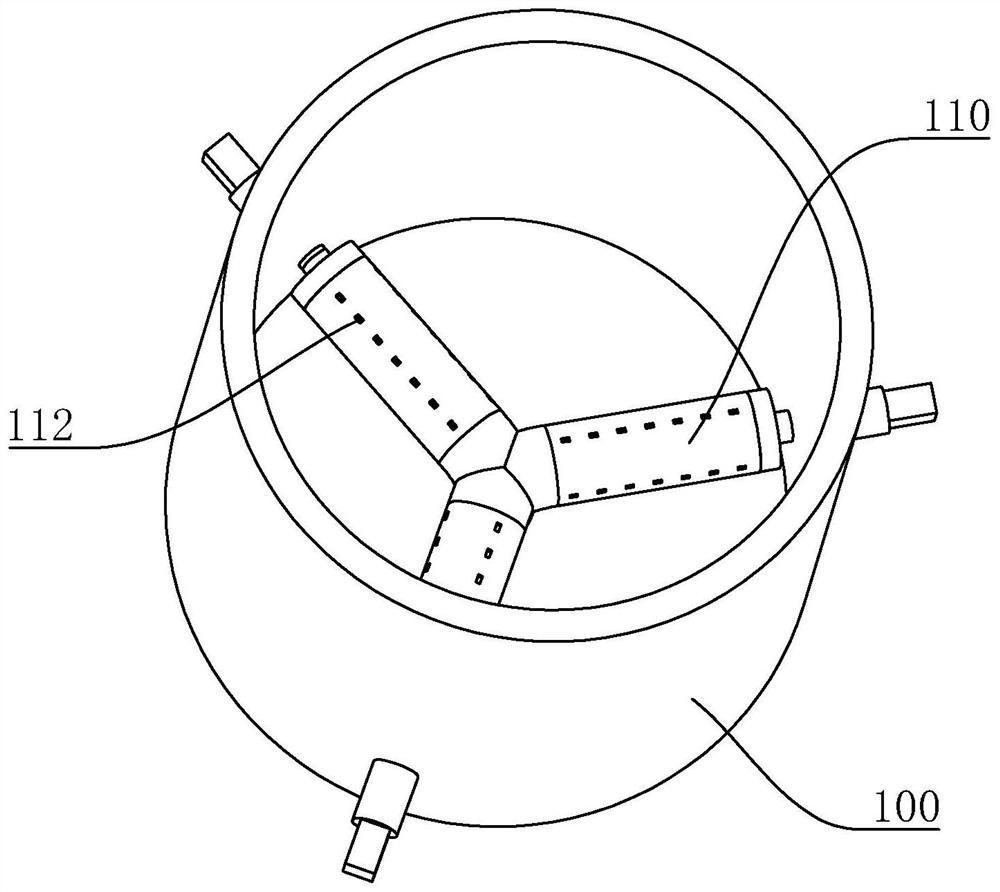

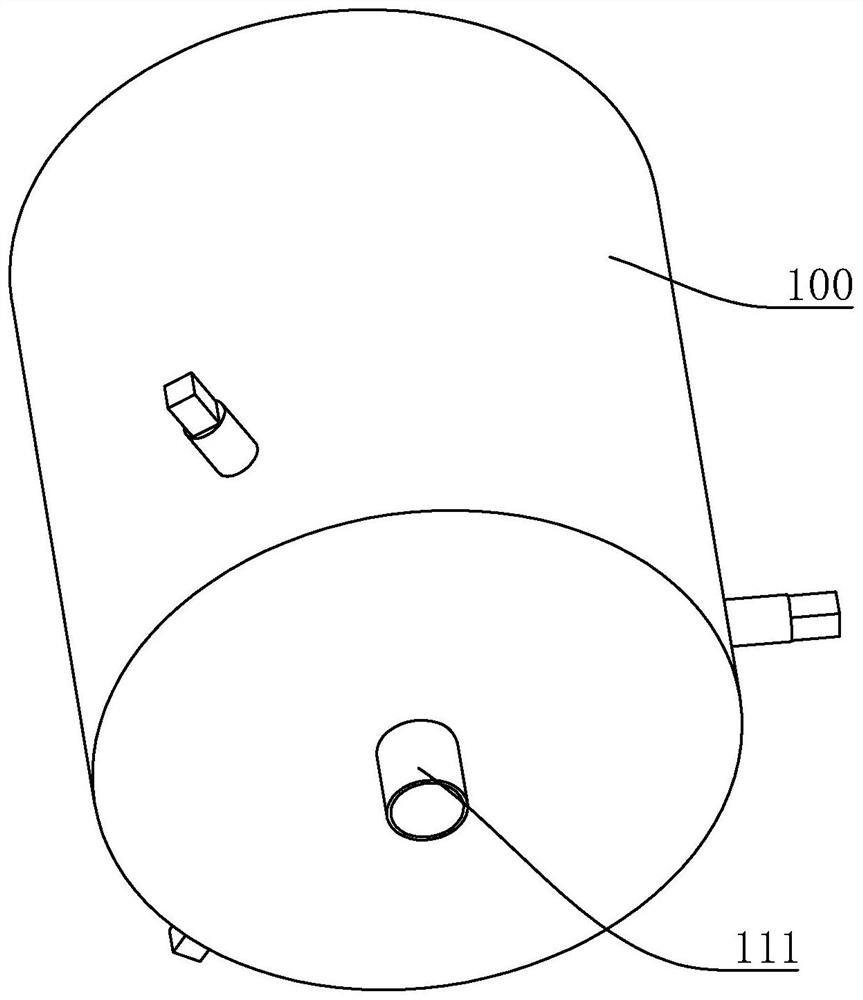

[0042] A kind of polyaluminum chloride water purification agent preparation device, refer to figure 1 , figure 2 , including the preparation tank body 100, the preparation tank body 100 is provided with pulse air pipes 110, and in this embodiment, there are three pulse air pipes 110 evenly distributed along the circumferential direction, and the pulse air pipes 110 are arranged radially, and the end at the center of the circle is connected to the air delivery pipe 111, The air pipe 111 is connected with an air source. A number of air holes 112 are evenly distributed on the pulse air tube 110 .

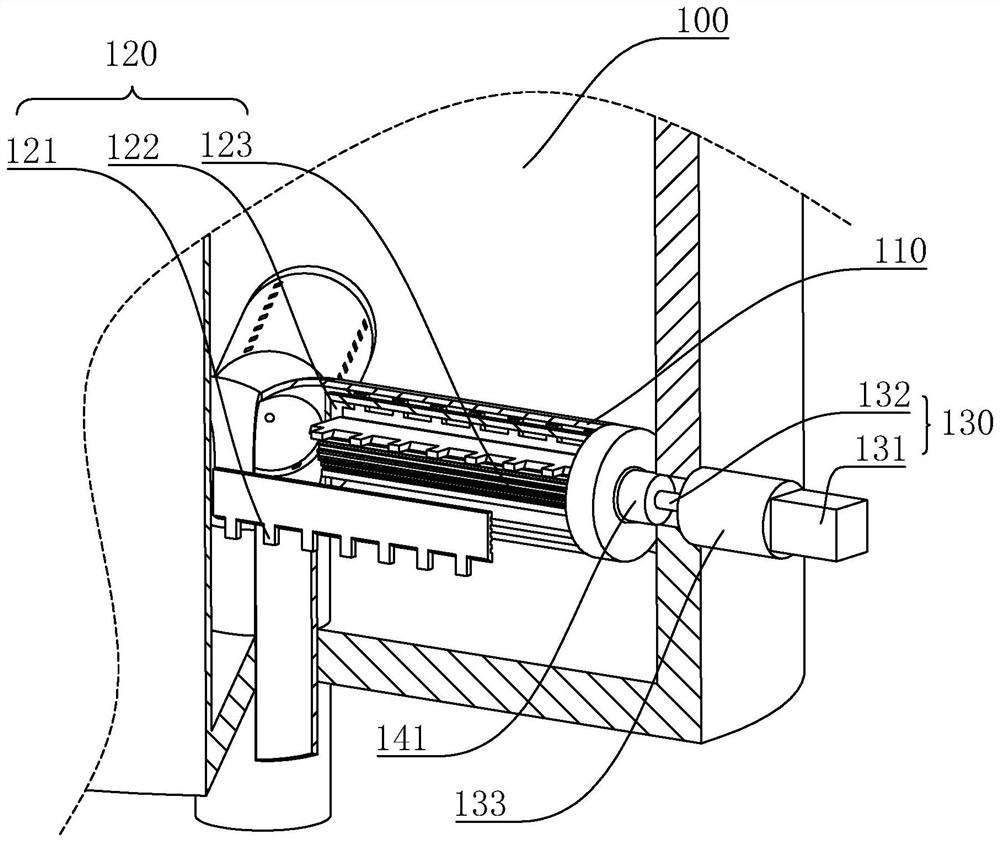

[0043] refer to image 3 , Figure 4, the pulse air tube 110 is provided with a dredging component 120 for dredging the blockage in the air hole 112 . The dredging assembly 120 includes a dredging head 121 that is slidably connected to the pulse air tube 110 and used to be inserted into the air hole 112 for dredging, a connecting sleeve 122 arranged in the pulse air tube 110, and ...

Embodiment 2

[0050] The difference from Example 1 is that, referring to Figure 8 , the rotating shaft 123 is a smooth surface, and the inner wall of the connecting sleeve 122 has several annular accommodating grooves 127 uniformly distributed along the length direction of the connecting sleeve 122, and the circumferential side wall of the rotating shaft 123 is provided with a rigid winding belt body 128, rigid winding The strip body 128 is a steel strip body, and the middle part of the cross section of the steel strip body is concavely arranged in an arc shape, so that the steel strip body can have two forms. Under the situation of external force, it can be wound on the rotating shaft 123. Under the straightened external force, due to the setting of the arc shape, it will maintain a straight line (such as Figure 9 shown).

[0051] One end of the rigid winding belt body 128 is fixedly connected to the outer wall of the rotating shaft 123. In the case of winding, it will be located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com