Water spraying filler system for waste gas treatment

A technology of spraying packing and waste gas treatment, which is applied in the direction of gaseous effluent wastewater treatment, aerobic process treatment, sustainable biological treatment, etc., and can solve the problems of reduced partial pressure of organic waste gas, secondary pollution, and reduction of VOC organic waste gas treatment efficiency, etc. problems, achieve the effects of preventing pollution, improving efficiency, and prolonging the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

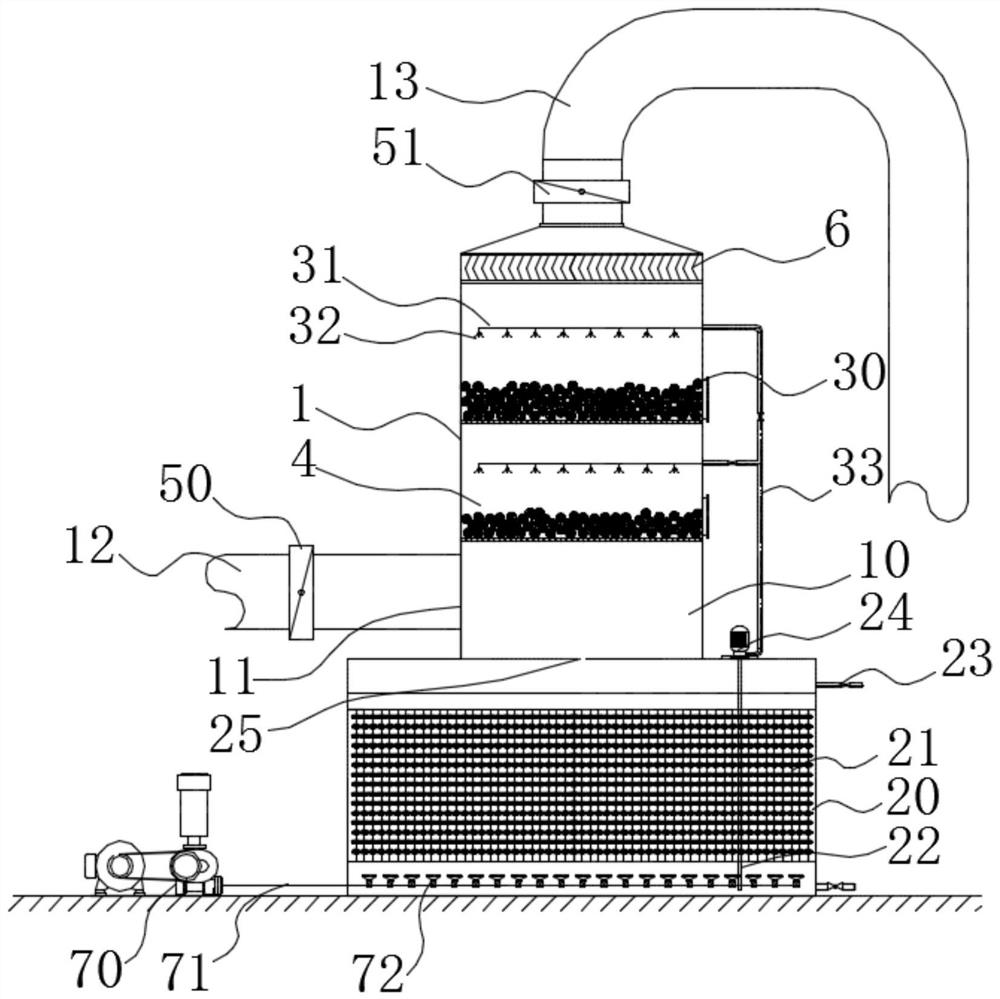

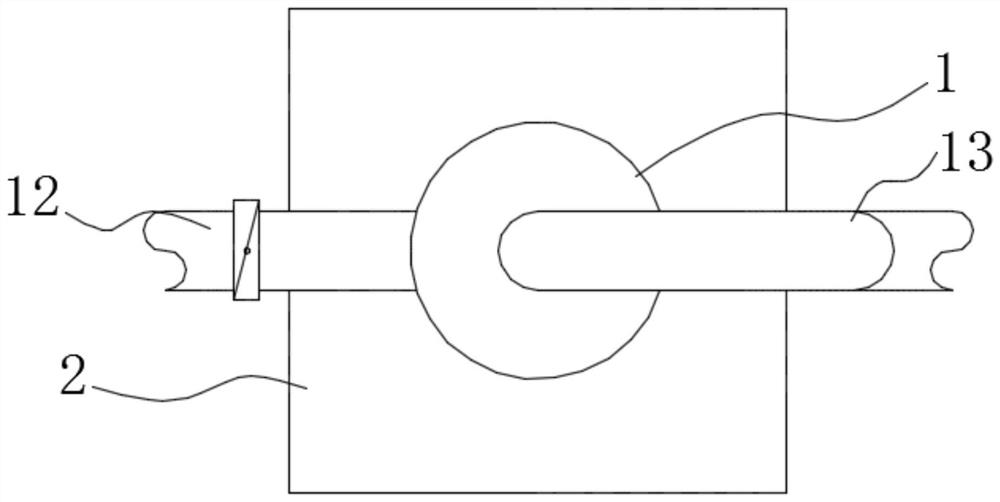

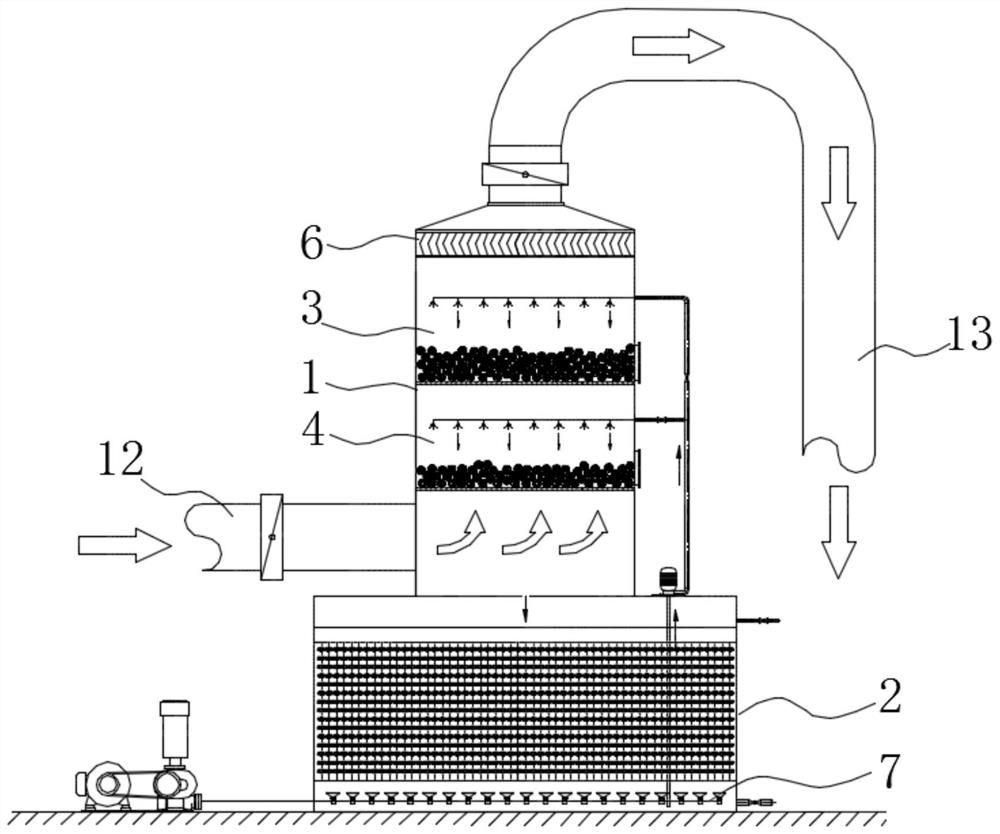

[0024] Please refer to Figure 1-Figure 3 , the present invention provides a water spray packing system for waste gas treatment, comprising: a spray packing tower 1, a water storage unit 2, a primary spray packing unit 3 arranged in the spray packing tower 1, at least A set of secondary spray packing unit 4, tower opening and closing control unit, the spray packing tower 1 is connected to the water storage unit 2 through a water inlet pipe 33, and the spray packing tower 1 is provided with an absorption chamber 10. The bottom of the spray packing tower 1 is provided with an air inlet 11 communicating with the absorption cavity 10, and the primary spray packing unit 3 and the secondary spray packing unit 4 are both arranged in the absorption chamber 10. In the chamber 10, the bottom of the absorption chamber 10 communicates with the water sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com