Printing and dyeing wastewater treatment device

A treatment device, a technology for printing and dyeing wastewater, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of difficult to filter impurities accumulation, affecting work efficiency, affecting filtration efficiency, etc., to improve filtration efficiency and use. High performance, strong adaptability, and the effect of avoiding the accumulation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

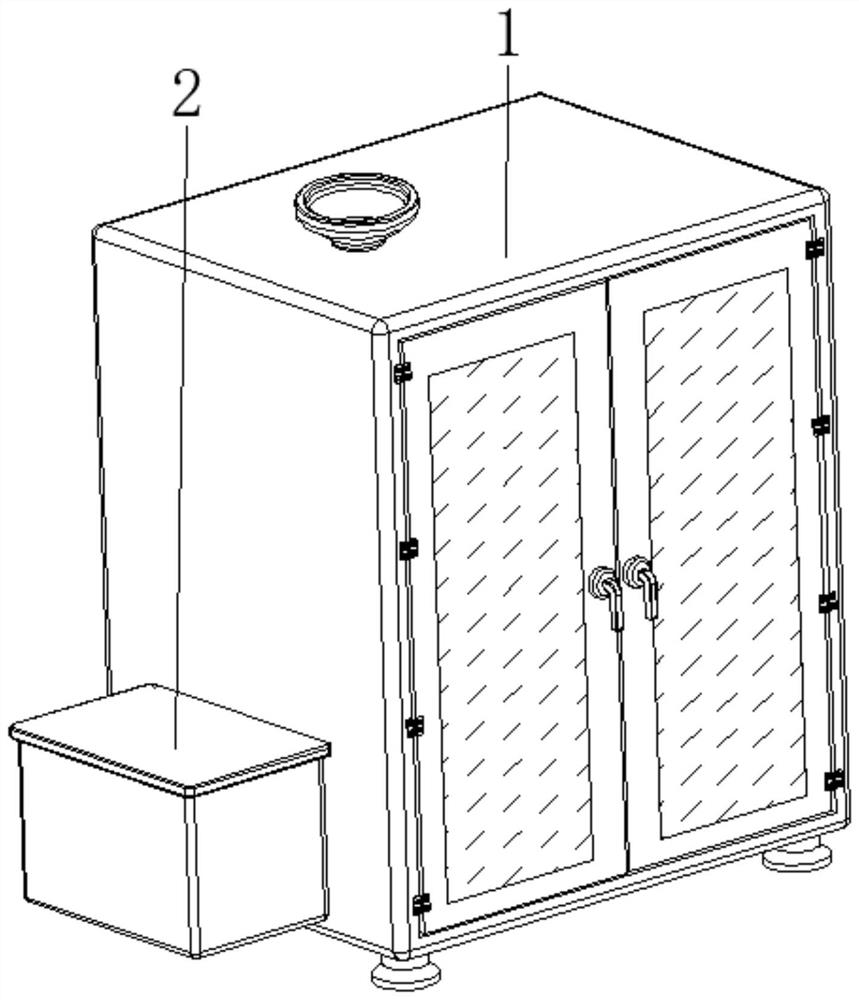

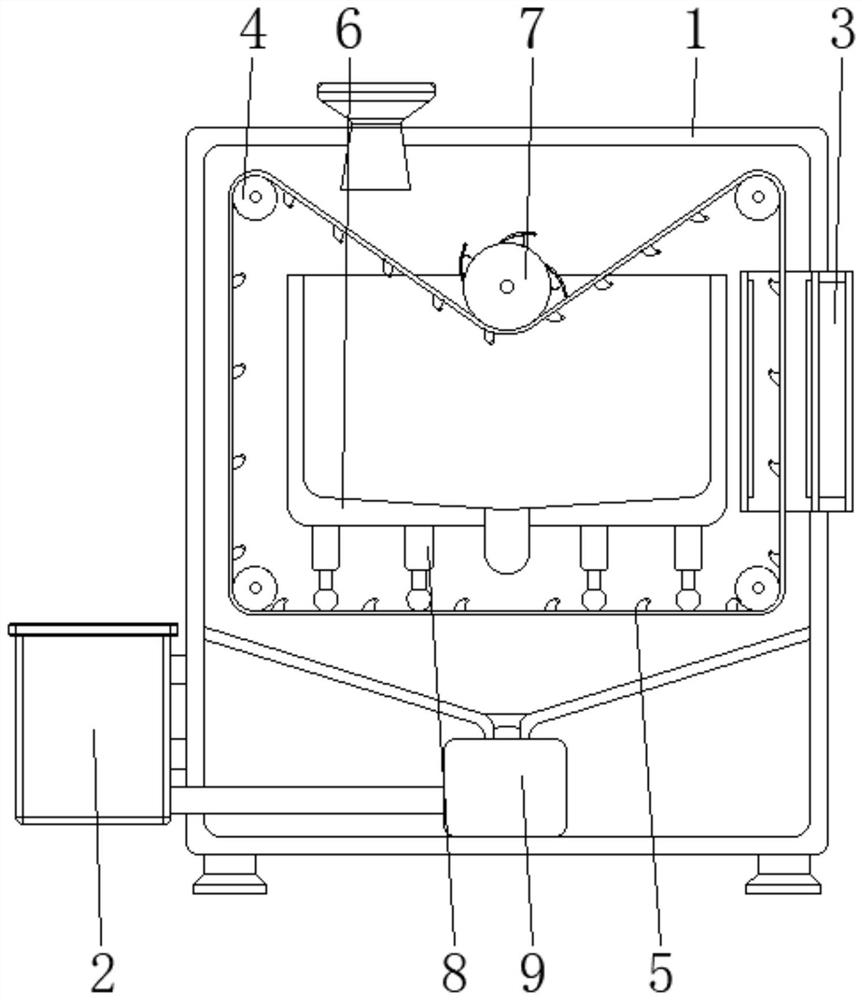

[0029] see Figure 1-6 , the present invention provides a technical solution: a printing and dyeing wastewater treatment device, including a box body 1, an impurity collection bin 2, and a heating mechanism 3, the impurity collection bin 2 is arranged on the bottom side of the surface of the box body 1, and the heating mechanism 3 is arranged on The top of the surface of the box body 1 and the side away from the impurity collection bin 2;

[0030] The inside of the box body 1 is provided with a driving roller 4, a conveying filter device 5, a water tank 6, a pressure roller device 7, a cleaning device 8, and an adsorption mechanism 9. The driving roller 4 is arranged inside the box body 1, and the conveying filter device 5 is arranged on the drive The surface of the roller 4 passes through the inside of the heating mechanism 3, the water tank 6 is arranged inside the box body 1, the pressure roller device 7 is rotatably connected between the two sides corresponding to the inne...

Embodiment example 2

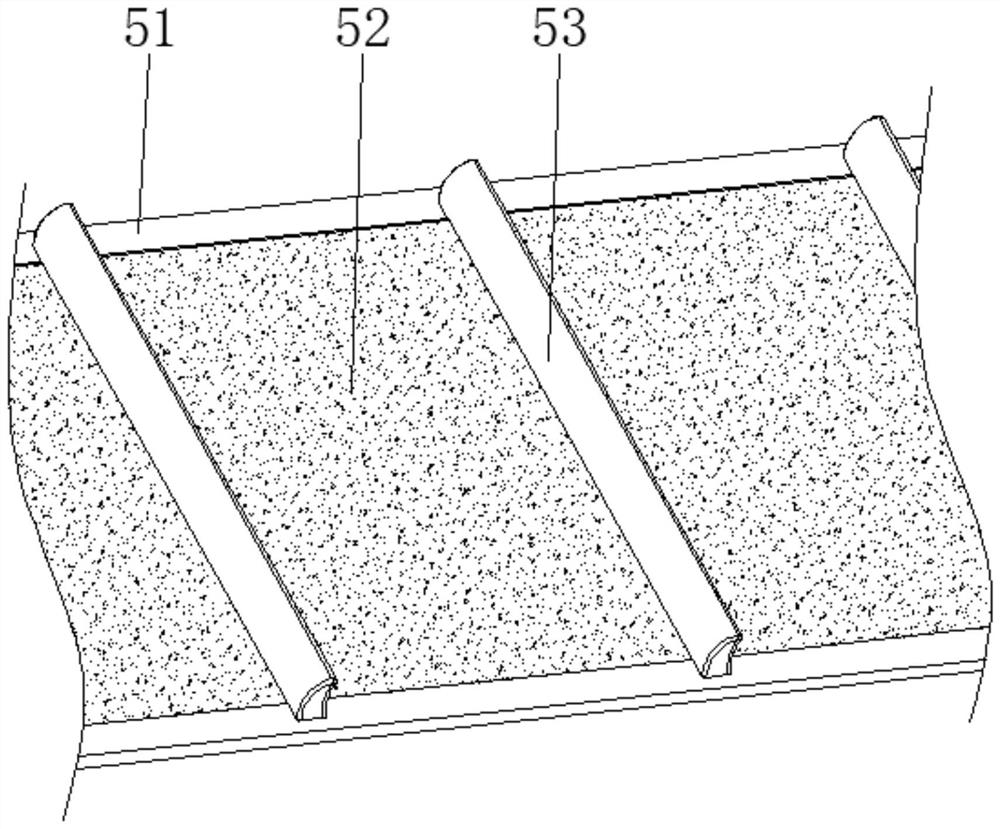

[0032] Conveying and filtering device 5 is provided with conveyor belt 51, elastic filter screen 52, curved surface scraper 53, and conveyor belt 51 is closed shape and is arranged on the surface of driving roller 4, and elastic filter screen 52 is arranged on the surface of conveyor belt 51, and arc surface The surface of the scraper 53 is fixedly connected to the surface of the conveyor belt 51. When the driving roller 4 drives the conveyor belt 51 through the curved scraper 53, the elastic filter 52 will also move accordingly. At this time, the printing and dyeing wastewater flows evenly to the elastic filter. The surface of the net 52 is filtered, and the accumulation of impurities can be avoided, which is helpful for filtering. At the same time, the cambered scraper 53 is used to cooperate with the driving roller 4 to achieve the purpose of synchronous operation, so as to prevent the viscous printing and dyeing wastewater Under the effect of, the phenomenon of slipping occ...

Embodiment example 3

[0034] The pressure roller device 7 is provided with a pressure roller main body 71, a pressure plate device 72, an arc spring 73, and an elastic bag 74. The end of the pressure roller main body 71 is rotatably connected to the inner wall of the water tank 6, and one end of the pressure plate device 72 is rotatably connected to the pressure roller. On the surface of the main body 71 , the elastic bag 74 is disposed between the surface of the platen device 72 and the corresponding two sides inside the main body 71 of the pressing roller.

[0035]The pressing plate device 72 is provided with an arc-shaped pressing plate 721 and an arc-shaped jet hole 722, and one end of the arc-shaped pressing plate 721 is rotationally connected to the surface of the roller main body 71. The arc-shaped air injection holes 722 are evenly distributed on the surface of the arc-shaped pressure plate 721. Using the pressing action of the pressure roller body 71, the conveyor belt 51 and the elastic fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com