Preparation process of high-protein sodium caseinate

A technology of sodium caseinate and preparation process, which is applied in the direction of animal protein processing, protein food ingredients, milk protein ingredients, etc. The effect of improving odor and increasing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

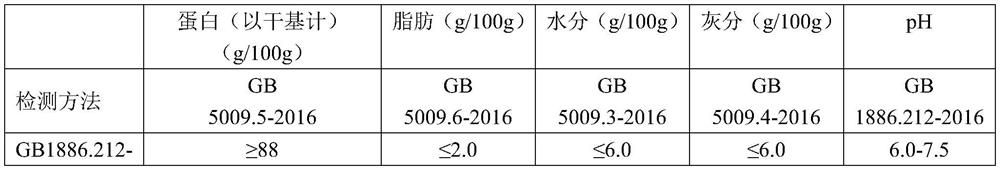

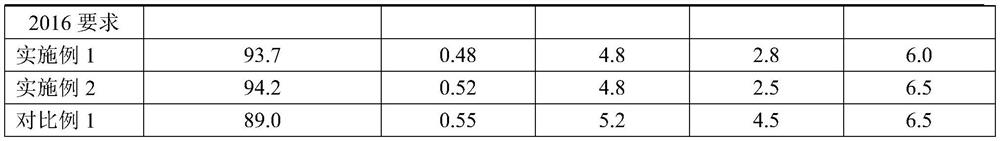

Examples

Embodiment 1

[0024] This embodiment provides a kind of preparation technology of high-protein sodium caseinate, and the steps are as follows:

[0025] Step 1: Crush Qula to 60 mesh, set aside;

[0026] Step 2: Put 1000kg of fresh milk into the dissolving tank, then add 30kg of Qula crushed in step 1, and then use 3.75kg of 0.6% sodium hydroxide solution to aid dissolution, the dissolution temperature is 50°C, and the time is 40min, to obtain mixture;

[0027] Step 3: using a centrifuge to degrease the mixed solution obtained in Step 2 at a speed of 6000 rpm to form a skim milk solution with a fat content of 0.005%;

[0028] Step 4: Vacuumize and deodorize the skim milk solution obtained in Step 3 for 20 minutes at a vacuum pressure of -0.35 bar, and continue to sterilize it at a temperature of 115° C. for 4 seconds;

[0029] Step 5: The skim milk solution treated in step 4 is subjected to isoelectric point precipitation method, and the casein in the skim milk solution is acid-precipitate...

Embodiment 2

[0034] This embodiment provides a kind of preparation technology of high-protein sodium caseinate, and the steps are as follows:

[0035] Step 1: Crush Qula to 100 mesh, set aside;

[0036] Step 2: Put 1,000 kg of 3% aqueous solution of fresh milk grade casein into the dissolving tank, then add 30 kg of Qula crushed in Step 1, and then use 4.0 kg of 0.6% sodium hydroxide to aid dissolution, and the dissolution temperature is 50°C , the time is 40min to obtain a mixed solution;

[0037] Step 3: using a centrifuge to degrease the mixed solution obtained in Step 2 at a speed of 7000 rpm to form a skim milk solution with a fat content of 0.004%;

[0038] Step 4: Vacuumize and deodorize the skim milk solution obtained in Step 3 for 20 minutes at a vacuum pressure of -0.60 bar, and continue to sterilize it at a temperature of 113° C. for 6 seconds;

[0039] Step 5: The skim milk solution treated in step 4 is subjected to isoelectric point precipitation method, and the casein in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com