Novel planting frame and system for high-density vertical planting and seedling raising

A high-density, planting rack technology, applied in the field of planting racks, can solve the problems of low planting density, long vegetable growth cycle, inconvenient operation, etc., and achieve the effect of increasing the planting area, shortening the growth cycle, and increasing the coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

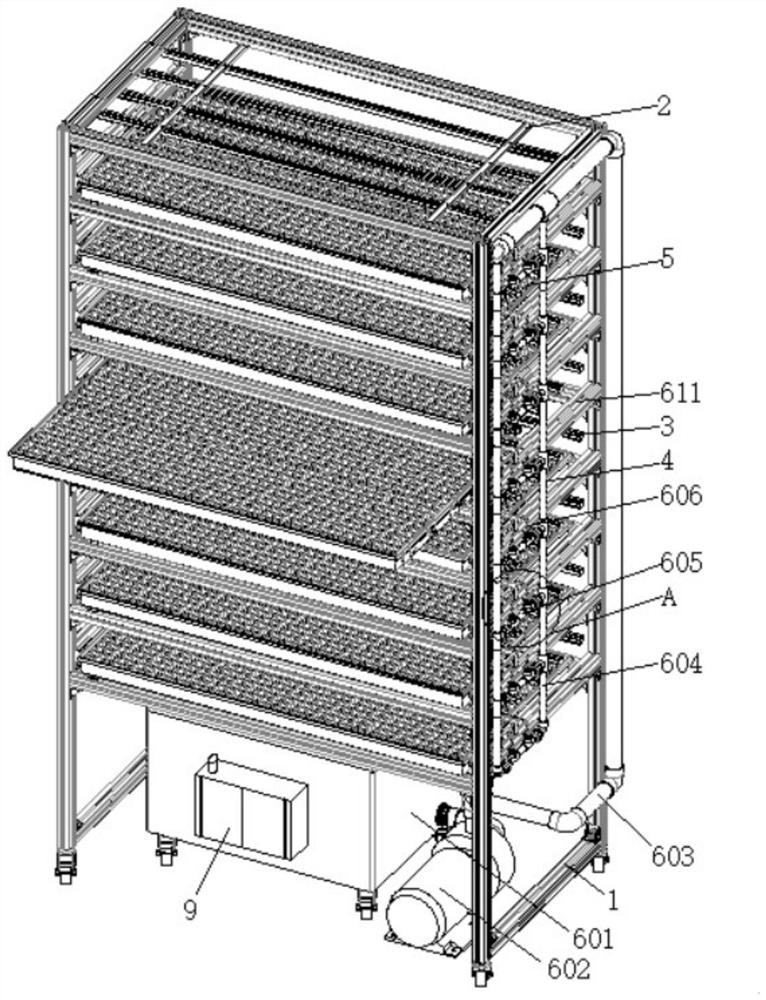

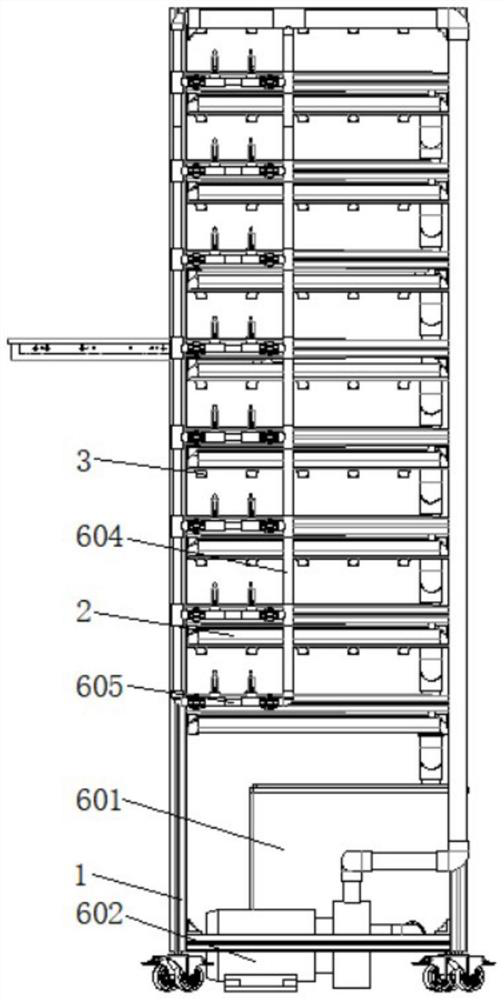

[0027] as attached figure 1 , figure 2 , image 3 and Figure 6 As shown, the present invention provides a novel high-density vertical planting and seedling-raising planting rack and system technical solution: a novel high-density vertical planting and seedling-raising planting rack and system, including, including a seedling-raising supporting frame 1 and an irrigation mechanism 6, With the control main box 9 arranged on the seedling-raising support frame 1, and several planting layers, the planting layer is provided with a cultivation tank 4, and drawer tracks 7 positioned on both sides of the training tank 4, between the training tank 4 and the drawer track 7 A fixed push block 8 compatible with the drawer track 7 is provided, and the fixed push block 8 is fixed on the cultivation tank 4 by bolts, and the cultivation tank 4 can be pushed into the inside of the supporting frame 1 for seedling cultivation, and the fixed push block 8 on the cultivation tank 4 can push the ...

Embodiment 2

[0029] The solution in Embodiment 1 will be further introduced in combination with specific working methods below, see the following description for details:

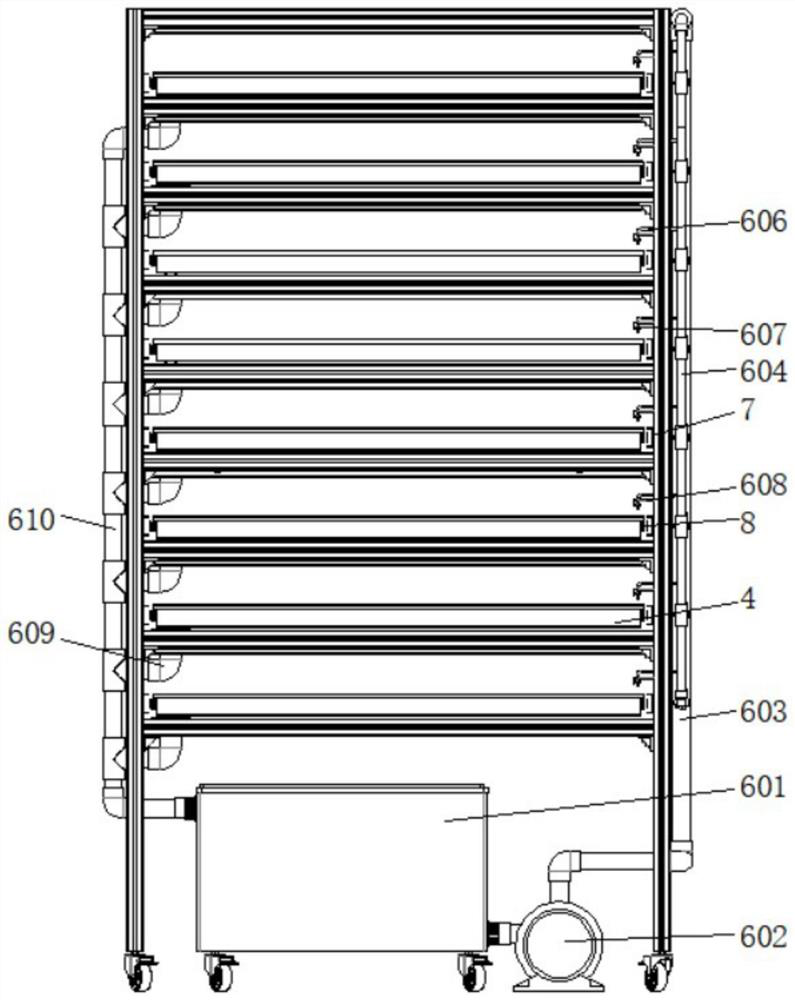

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, as a preferred embodiment, on the basis of the above method, further, the irrigation mechanism 6 includes a liquid supply tank 601, a liquid supply pump 602, a pump liquid pipe 603, a branch pipe 604, a fixed pipe 605, a spray pipe 606, a mist Nozzle 607, fixed bracket piece 608, return angle pipe 609, return main pipe 610 and return flow tank 611, liquid supply tank 601 is provided with liquid supply pump 602 and return main pipe 610, the liquid inlet of liquid supply pump 602 is connected to the supply liquid On the box 601, the liquid outlet of the liquid supply pump 602 is connected to the pump liquid pipe 603, and the pump liquid pipe 603 is connected to two branch pipes 604 arranged in parallel. The axial direction of the branch pipe 604 is p...

Embodiment 3

[0032] The schemes in Embodiment 1 and Embodiment 2 are further introduced in conjunction with specific working methods below, see the following description for details:

[0033] Such as Figure 5 As shown, a new planting system for high-density vertical planting and seedling cultivation includes a control main box 9, and the control main box 9 includes a control box housing 901, a micro-control chip 902, a temperature sensor 903, a humidity sensor 904, and a water level pressure sensor 905 , water pressure pressure sensor 906, light brightness sensor 907, PLC controller 908, smoke alarm 909, warning light 910 and buzzer alarm 911, control box housing 901 is provided with micro-control chip 902, and with micro-control chip 902 connected temperature sensor 903, humidity sensor 904, water level pressure sensor 905, water pressure pressure sensor 906 and light brightness sensor 907, the output end of micro-control chip 902 is connected with PLC controller 908, smoke alarm 909, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com