Precise guide rail for CNC machine tool

A technology for precision guide rails and CNC machine tools, applied in the field of precision guide rails, can solve the problems of friction consumption of sliders and rails, affecting normal use, and low practicability, and achieve the effects of reducing use loss, improving practicability, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

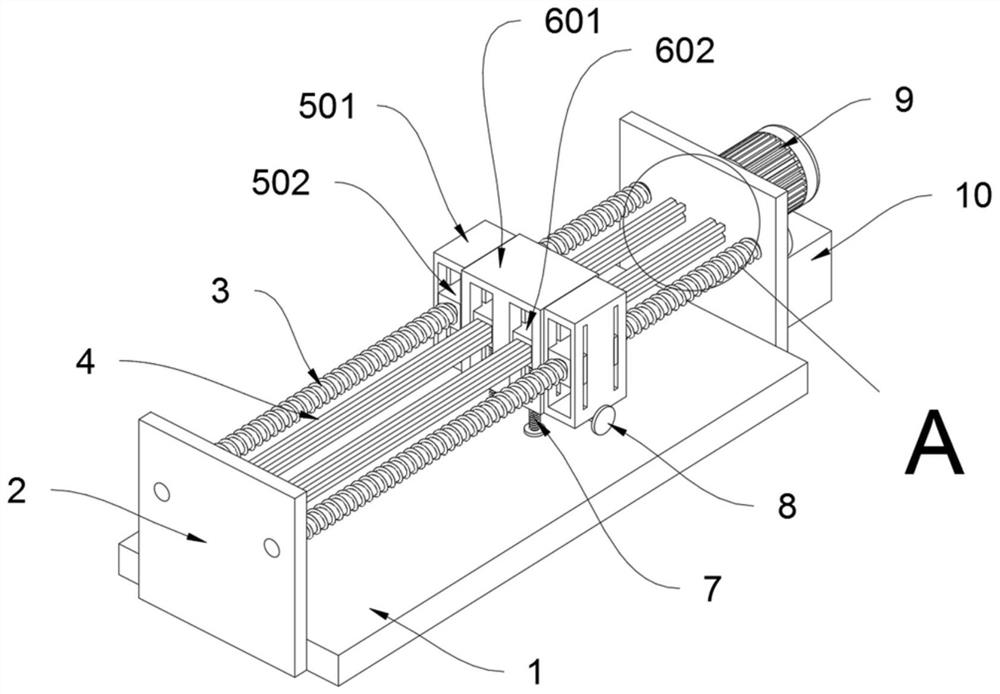

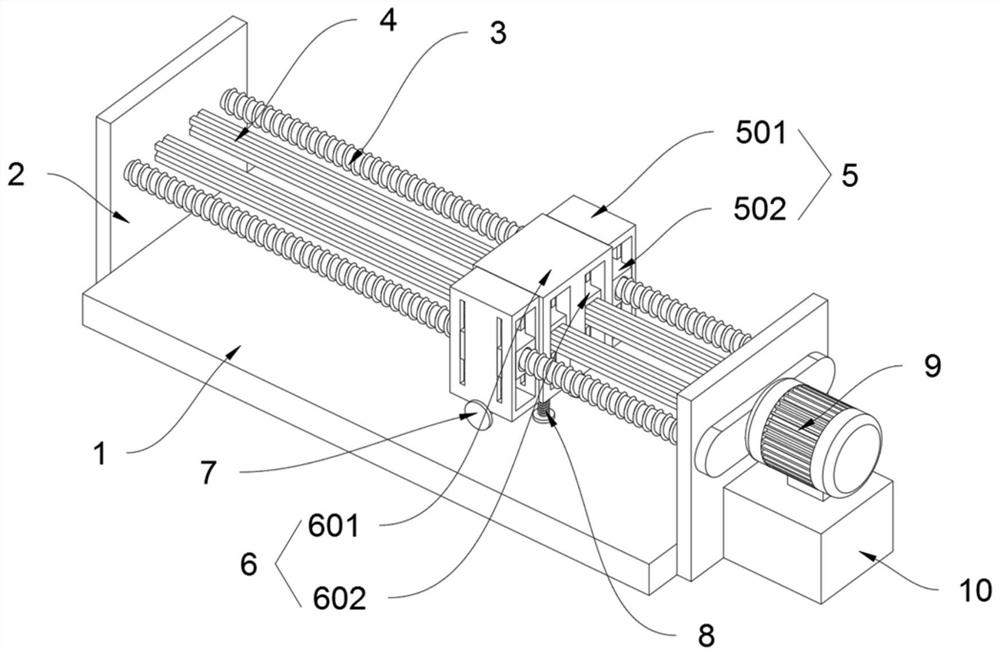

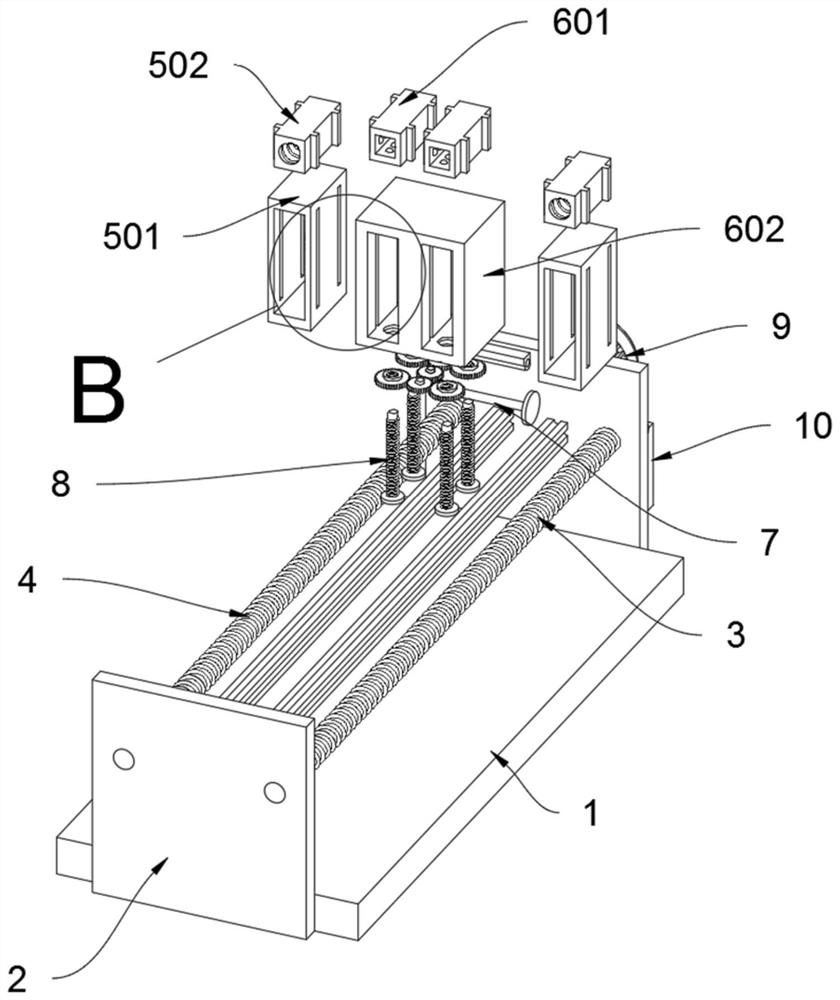

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides a precision guide rail for CNC machine tools, comprising a guide rail platform 1, a drive shaft 3, a guide rail column 4, a drive mechanism 5, a guide rail mechanism 6, an adjustment mechanism 7, a positioning rod 8 and a drive motor 9; the guide rail platform 1 Both sides of the drive shaft 3 are fixedly connected to the support plate 2; the two ends of the drive shaft 3 are rotatably connected to the inside of the support plates 2 on both sides of the guide rail platform 1; the two ends of the guide rail column 4 are fixedly connected to the inside of the support plates 2 on both sides of the guide rail platform 1, And the rail post 4 is located inside the drive shaft 3; the drive mechanism 5 is made up of a drive sleeve 501 and a drive block 502; the drive block 502 is plugged in the drive sleeve 501, and the drive shaft 3 is plugged in the drive block 502; The shaft body of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com