Method for preparing methanol by coupling gasification of pulverized coal waste boiler with green electricity and green hydrogen to realize near-zero carbon emission

A carbon emission and pulverized coal technology, which is applied in the field of methanol preparation, can solve the problems of zero utilization of carbon elements, waste of carbon elements, carbon emission, etc., and achieve the effect of reducing carbon emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

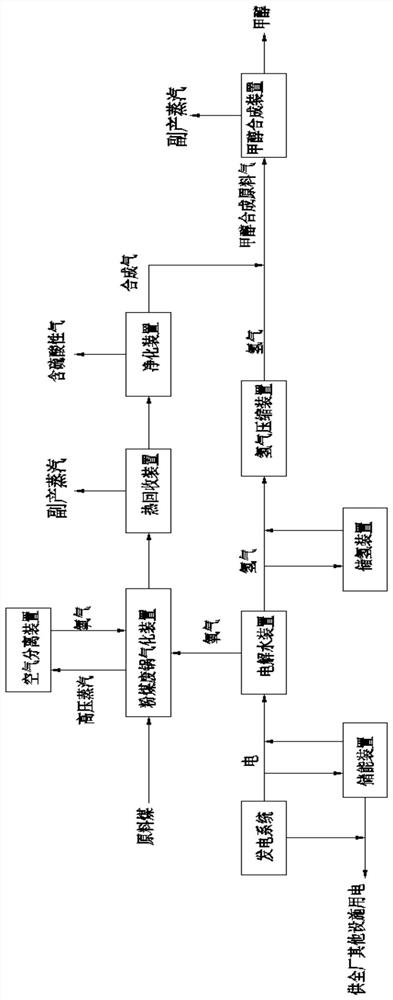

[0022] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing methanol with nearly zero carbon emission by gasification of waste pulverized coal boiler coupled with green electricity and green hydrogen. Including the following steps:

[0023] (1) The oxygen produced by the air separation unit and the oxygen by-product of the electrolysis unit react with coal in the pulverized coal waste boiler gasification unit to obtain high-temperature synthesis gas, which is sent to the heat recovery unit for further heat recovery;

[0024] (2) The pulverized coal waste boiler gasification device recovers the heat of high-temperature synthesis gas through the waste heat boiler and steam superheater, produces 6.0-13.0MPaG superheated steam, and sends it to the air separation device to drive the air compressor turbine;

[0025] (3) The synthesis gas from the heat recovery unit is sent to the purification unit, only sulfuric acid-containing gas is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com