Preparation method of carbon fiber reinforced silicon carbide ceramic matrix composite corrugated sandwich plate

A technology of silicon carbide ceramic matrix and composite materials, which is applied in the field of preparation of carbon fiber reinforced silicon carbide ceramic matrix composite material corrugated sandwich panels, can solve the problems of inability to fly for a long time, fuel consumption, etc., and achieve reliable connection, low cost, lightening effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

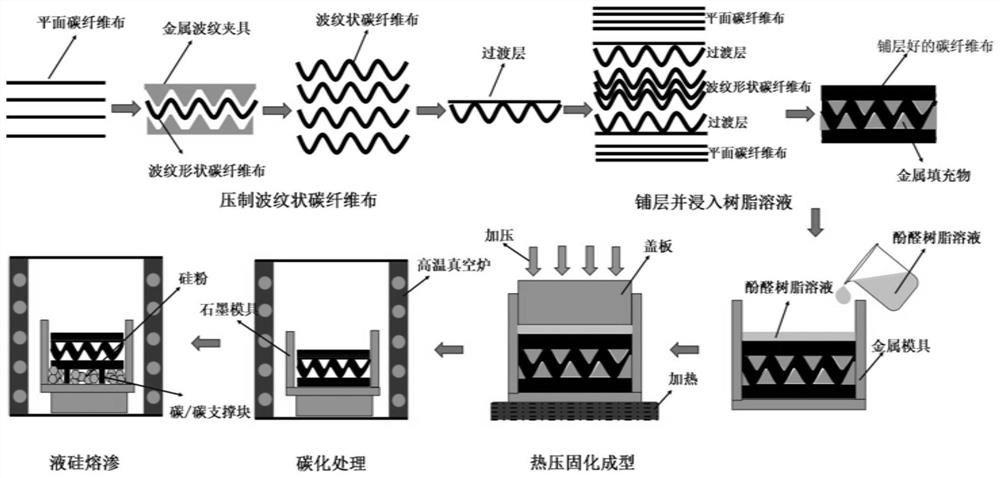

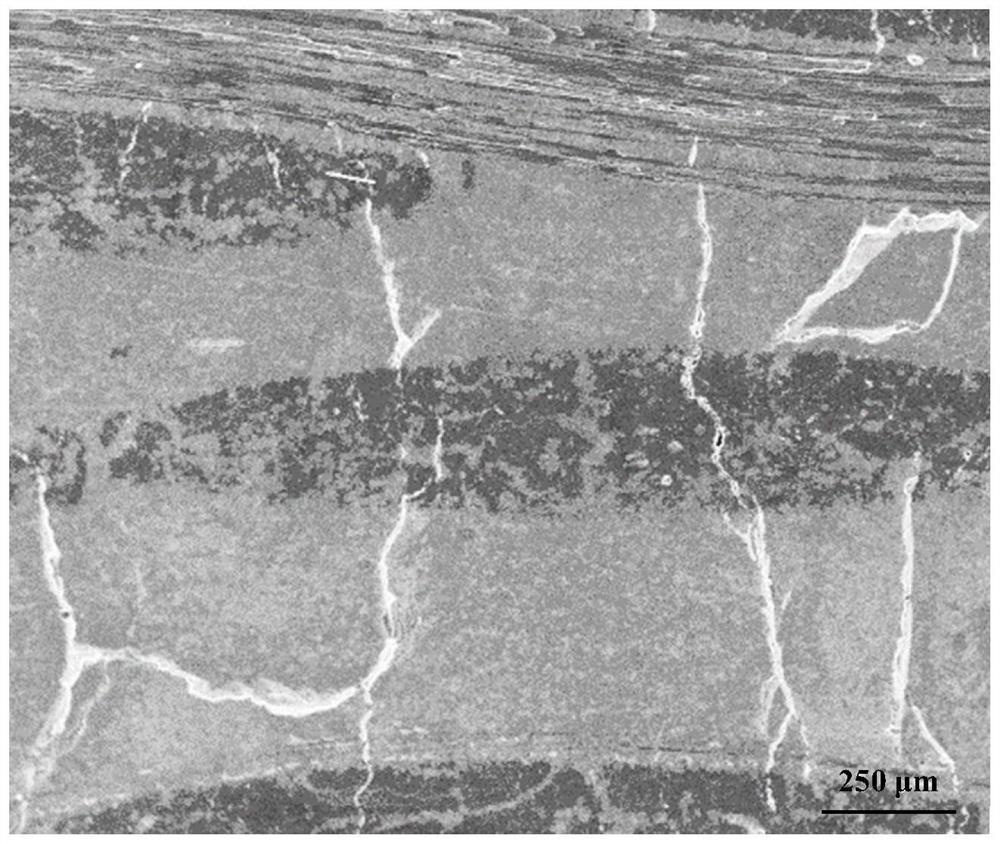

[0024] Embodiment 1: Step 1, pressing corrugated carbon fiber cloth: first dissolving phenolic resin particles in anhydrous ethanol solution to prepare a phenolic resin solution with a mass fraction of 10%, and then spraying the phenolic resin solution evenly along the orthogonal direction On the surface of the two-dimensional carbon fiber cloth, the two-dimensional carbon fiber cloth is clamped by a metal corrugated fixture and placed in an oven. After baking at 35°C for 30 minutes, the fixture is removed to form a corrugated carbon fiber cloth.

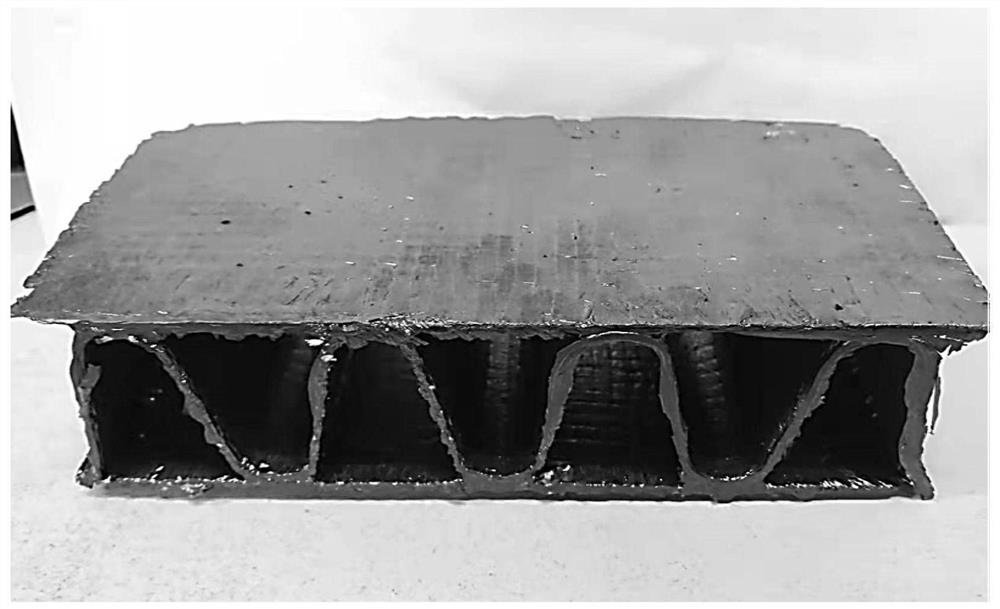

[0025] Step 2, layering and immersing in resin solution: First, take one piece of corrugated carbon fiber cloth and one piece of flat carbon fiber cloth obtained in step 1, and stitch the crests or troughs where the corrugated carbon fiber cloth and flat carbon fiber cloth meet to obtain transition layer; then lay several layers of flat carbon fiber cloth, one transition layer, several layers of corrugated carbon fiber cloth, one tra...

Embodiment 2

[0029]Embodiment 2: Step 1, pressing the corrugated carbon fiber cloth: first dissolving the phenolic resin particles in absolute ethanol solution to prepare a phenolic resin solution with a mass fraction of 8%, and then spraying the phenolic resin solution uniformly along the direction of 45 ° On the surface of the two-dimensional carbon fiber cloth, the two-dimensional carbon fiber cloth is clamped by a metal corrugated fixture and placed in an oven. After baking at 30°C for 40 minutes, the fixture is removed to form a corrugated carbon fiber cloth.

[0030] Step 2, layering and immersing in resin solution: First, take one piece of corrugated carbon fiber cloth and one piece of flat carbon fiber cloth obtained in step 1, and stitch the crests or troughs where the corrugated carbon fiber cloth and flat carbon fiber cloth meet to obtain transition layer; then lay several layers of flat carbon fiber cloth, one transition layer, several layers of corrugated carbon fiber cloth, on...

Embodiment 3

[0034] Embodiment 3: Step 1, pressing corrugated carbon fiber cloth: first dissolving phenolic resin particles in anhydrous ethanol solution to prepare a phenolic resin solution with a mass fraction of 15%, and then spraying the phenolic resin solution evenly along the direction of 60 ° On the surface of the two-dimensional carbon fiber cloth, the two-dimensional carbon fiber cloth is clamped by a metal corrugated fixture and placed in an oven. After baking at 40°C for 20 minutes, the fixture is removed to form a corrugated carbon fiber cloth.

[0035] Step 2, layering and immersing in resin solution: First, take one piece of corrugated carbon fiber cloth and one piece of flat carbon fiber cloth obtained in step 1, and stitch the crests or troughs where the corrugated carbon fiber cloth and flat carbon fiber cloth meet to obtain transition layer; then lay several layers of flat carbon fiber cloth, one transition layer, several layers of corrugated carbon fiber cloth, one transi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com