Advanced treatment device and process for high-salt degradation-resistant sewage

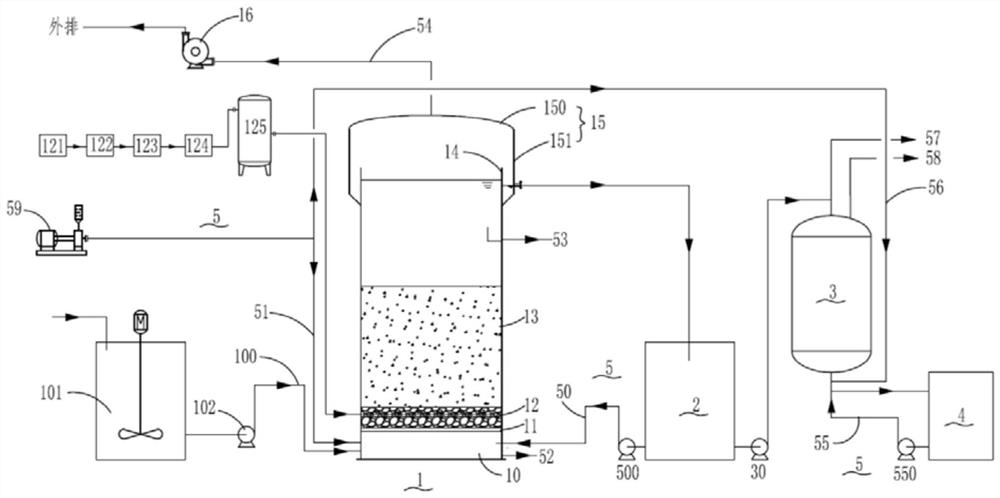

It is an advanced treatment and refractory technology, which is applied in the direction of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high operating cost and poor treatment effect, and achieve operating cost Low, increased adsorption capacity, deep and efficient degradation treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0100] The treated sewage is: ultrafiltration reverse osmosis concentrated water of a refining and chemical enterprise, COD 150mg / L, TDS 30g / L;

[0101] The treatment process is: carry out according to the above-mentioned procedure of the present invention, wherein the specific surface area of the block activated carbon is 950 m 2 / g, pore volume 1.3mL / g, bulk density 0.5g / cm 3 , inoculation of salt-tolerant high-efficiency biological flora (75% of bacillus, 25% of nitrifying bacteria), the gas-water ratio is 5:1, and the residence time of the biological activated carbon reactor is 12h;

[0102] The treatment result is: the concentration of COD in the effluent is 17mg / L, and the concentration of suspended solids in the effluent after sand filtration is 15mg / L.

Embodiment 1-2

[0104] The treated sewage is: ultrafiltration reverse osmosis concentrated water of a refining and chemical enterprise, COD 150mg / L, TDS 30g / L;

[0105] The treatment process is: carry out according to the above-mentioned procedure of the present invention, wherein the specific surface area of the block activated carbon is 950 m 2 / g, pore volume 1.3mL / g, bulk density 0.5g / cm 3 , inoculation of salt-tolerant high-efficiency biological flora (50% of bacillus, 50% of nitrifying bacteria), the gas-water ratio is 5:1, and the residence time of the bioactivated carbon reactor is 8h;

[0106] The treatment result is: the concentration of COD in the effluent is 25mg / L, and the concentration of suspended solids in the effluent after sand filtration is 17mg / L.

Embodiment 1-3

[0108] Sewage treatment: ultrafiltration reverse osmosis concentrated water of a refining and chemical enterprise, COD 150mg / L, TDS 30g / L;

[0109] The treatment process is: carry out according to the above-mentioned procedure of the present invention, wherein the specific surface area of the block activated carbon is 950 m 2 / g, pore volume 1.3mL / g, bulk density 0.5g / cm 3 , inoculation of salt-tolerant high-efficiency biological flora (65% of bacillus, 40% of nitrifying bacteria), the gas-water ratio is 3:1, and the residence time of the biological activated carbon reactor is 12h;

[0110] The treatment results are: the concentration of COD in the effluent is 21mg / L, and the concentration of suspended solids in the effluent after sand filtration is 17mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com