Barrel winding device for motorcycle silencer production

A winding device and muffler technology, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc., can solve the problems of increased noise, scattered sound-proof fiber tapes, and insufficient packaging, so as to reduce the increase in noise, Prevent jamming and prevent the effect of not being tight enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

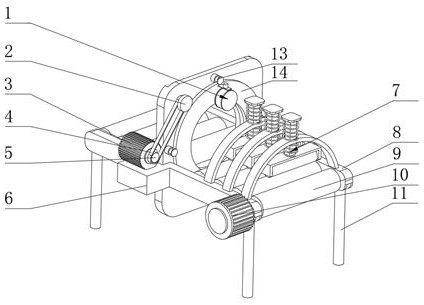

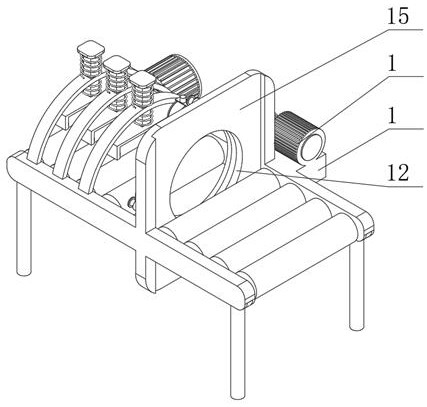

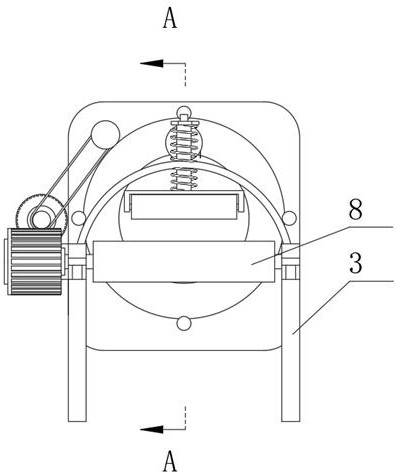

[0032] Such as figure 1 , 2 , 3, 4, 5, and 6, the embodiment of the present invention provides a cylinder winding device for motorcycle muffler production, including a fixed rod 8, and several A first conveying shaft 9, a fixed plate 15 is fixedly installed in the center of the two fixed rods 8, and four fixed rotating shafts 13 are movably installed on one side surface of the fixed plate 15 through the rotating shaft. A circular winding disc 14 is movably installed between the rotating shafts 13, a cut-off winding mechanism 1 is fixedly installed on one side surface of the circular winding disc 14, and a compression conveying mechanism is fixedly installed on the upper surface of one end of the fixed rod 8 7. The truncated winding mechanism 1 includes a connecting column 106, and the connecting column 106 is fixedly installed on one side surface of the circular winding disk 14. The pressing and conveying mechanism 7 includes a semicircular fixing rod 702, and the semicircula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com