Shaping device of precise continuous cold punching die

A shaping device and continuous technology, applied in the fields of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive, troublesome installation and disassembly, and achieve the effect of ensuring accurate installation, improving heat dissipation efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

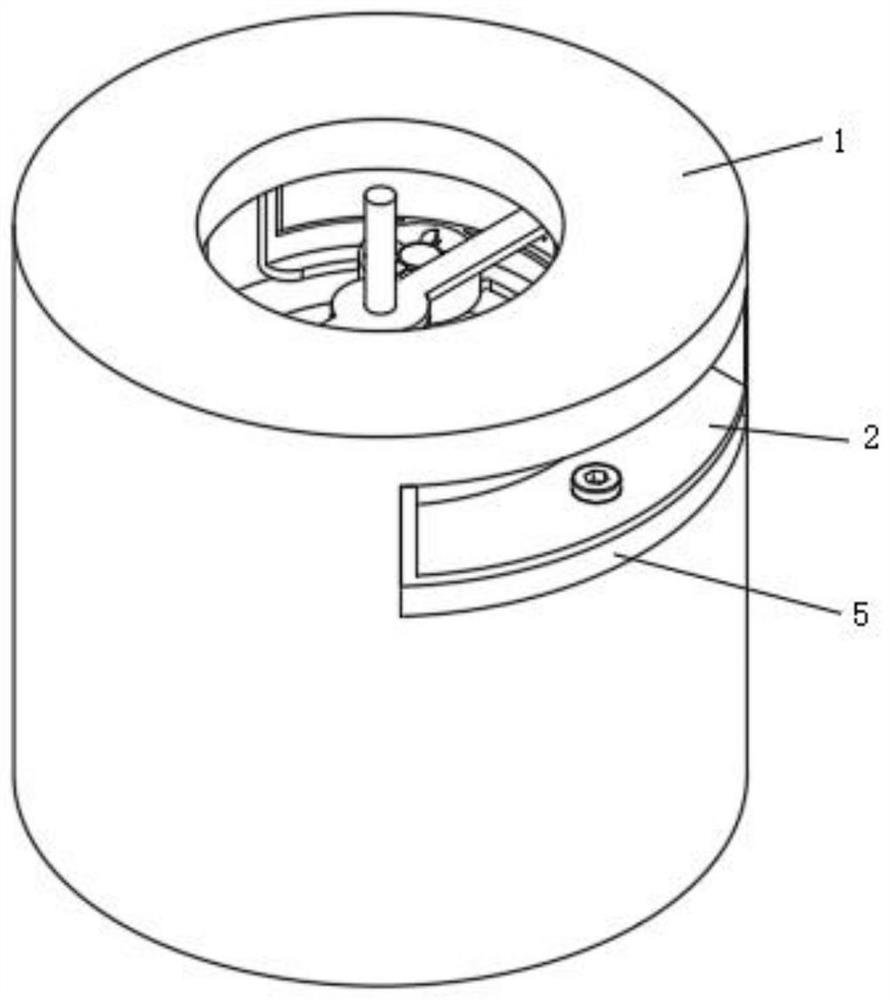

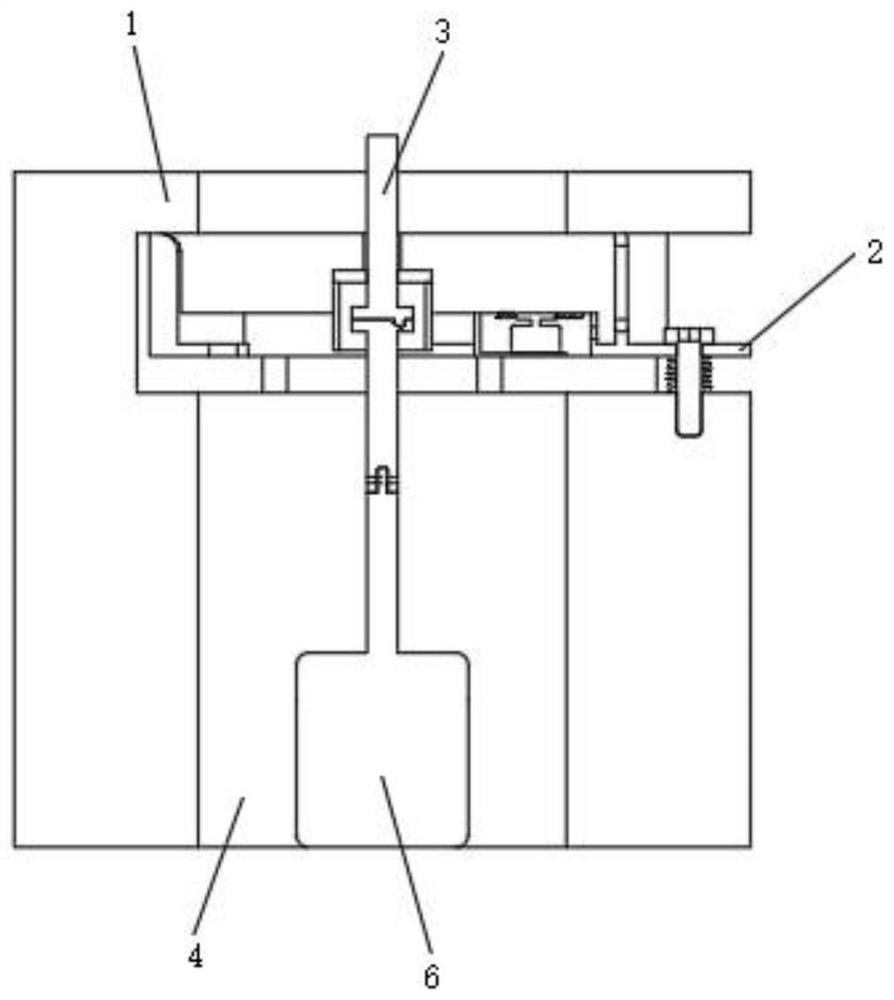

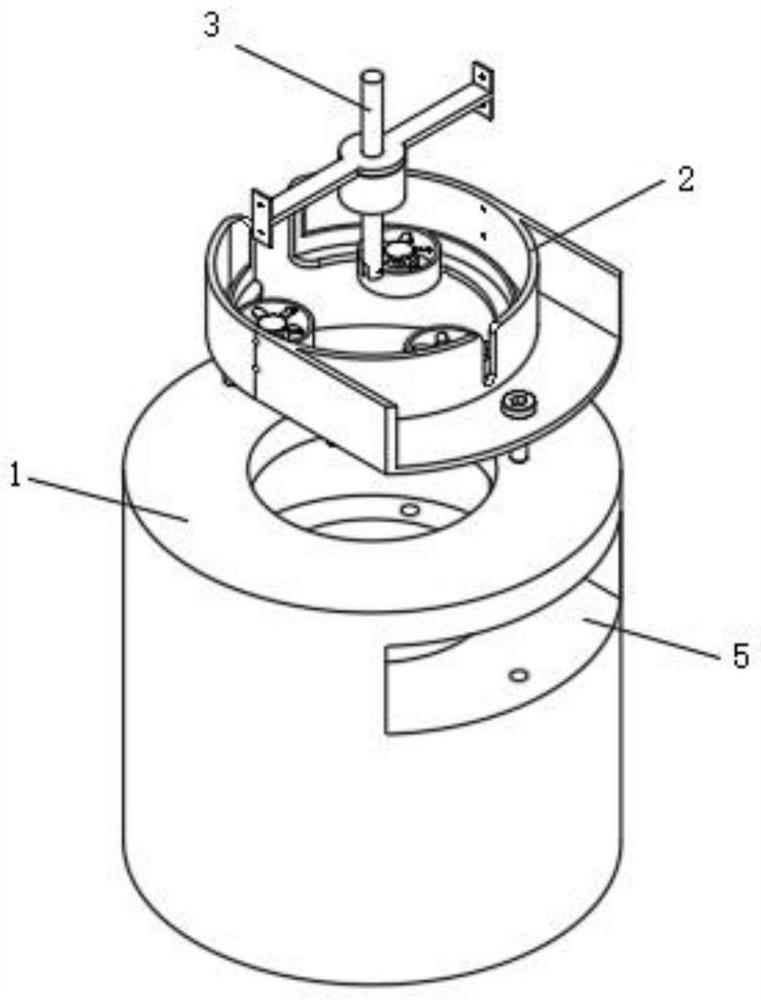

[0033] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, a shaping device for a precision continuous cold stamping die, including a base 1, a through hole 4 and a drive motor 6, the end face of the base 1 is provided with a through hole 4, the through hole 4 A drive motor 6 is provided at the bottom of the hole;

[0034] The upper part of the side wall of the base 1 is provided with an embedding groove 5, and a quick-mounting heat sink 2 is embedded in the groove of the embedding groove 5, and the interior of the quick-mounting heat sink 2 is provided with a quick-mounting limiter adapted to the drive motor 6 3;

[0035] The quick-mounted cooling device 2 includes a quick-mounted seat 201, an inner ring 202, a mounting cover 203, a fan 204, a wire hole 205, a docking hole 206, a gap 207, a groove 208, a jack 209, a fastening bolt 210, a spring 211 and Limiting post 212, in the groove of embedding groove 5, be embedded with fast loading seat 201, the upper end of fast loading seat 2...

Embodiment 2

[0038] Such as figure 1 , 2 , 3, 4, and 7, wherein the same or corresponding components as those in Embodiment 1 are designated with reference numerals corresponding to Embodiment 1. For the sake of brevity, only the differences from Embodiment 1 are described below. The difference is that the quick-installation cooling device 2 also includes a screw hole 213, the inner wall of the quick-installation seat 201 is provided with a screw hole 213, and the quick-installation limiting device 3 includes a connecting frame 301, a limit cover 302, a quick-installation Rod 303, connecting head 304, connecting seat 305 and fixed rod 306, the inner side wall of quick mounting seat 201 is provided with screw hole 213 places and is connected with connecting frame 301, and the middle part of the lower end of connecting frame 301 is provided with limit cover 302, and connecting frame 301 A quick-loading rod 303 is inserted into the opening in the middle of the upper end of the upper end, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap