Drilling optimization method for extracting coal seam gas by drilling

An optimization method, coal seam gas technology, applied in the direction of gas discharge, earthwork drilling, design optimization/simulation, etc., can solve problems such as increased construction costs, lack of theoretical basis for drilling parameter design, and substandard drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

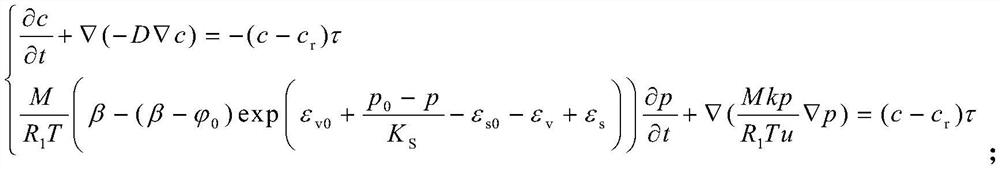

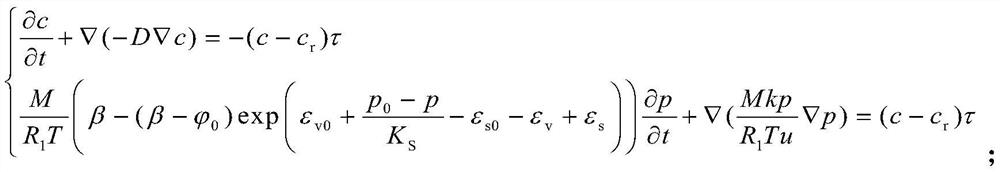

Method used

Image

Examples

Embodiment Construction

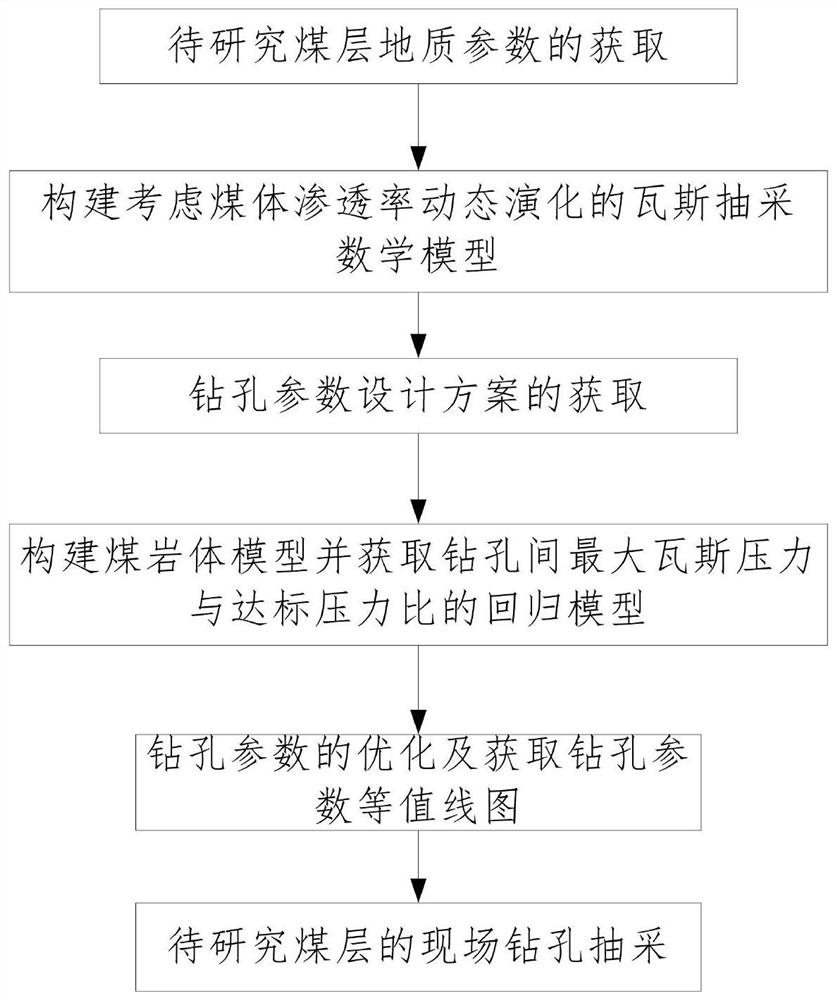

[0069] Such as figure 1 A drilling optimization method for drilling coal seam gas extraction is shown, the method includes the following steps:

[0070] Step 1. Acquisition of geological parameters of the coal seam to be studied:

[0071] Step 101. Obtain the regional geological parameters of the coal seam to be studied through exploration; wherein, the regional geological parameters of the coal seam to be studied include coal body density ρ c , elastic modulus E, shear modulus G, Poisson's ratio v, effective stress coefficient β, coal body temperature T, coal body initial porosity Coal bulk modulus K s , gas molar mass M, Langmuir volume adsorption constant a, Langmuir pressure adsorption constant b, gas dynamic viscosity coefficient u, gas diffusion coefficient D, gas desorption diffusion coefficient τ, gas density ρ in the standard state ga , molar gas constant R 1 ;

[0072] Step 102, obtaining the vertical stress F of the coal seam to be studied;

[0073] Step 103,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com