Nanowire structure copper/cuprous sulfide/copper mesh electrode material and preparation method and application thereof

An electrode material, cuprous sulfide technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the limitations and other problems, and achieve the effect of lower energy barrier, good conductivity, and large electrochemical active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

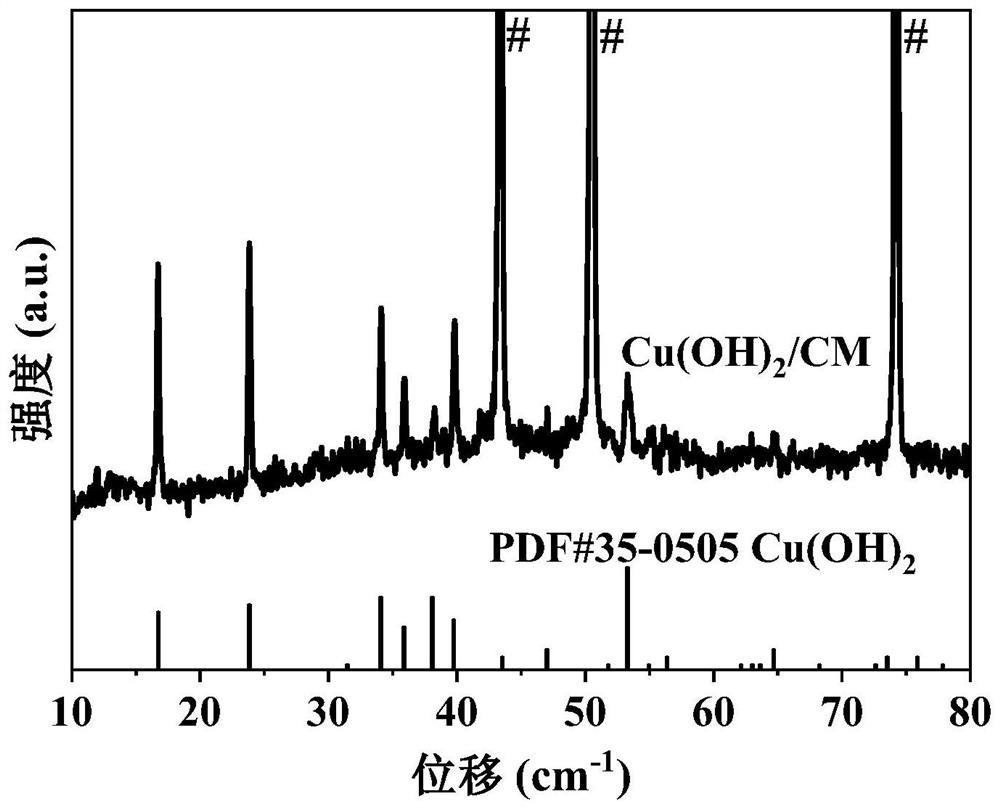

[0045] A. Preparation of copper hydroxide / copper mesh.

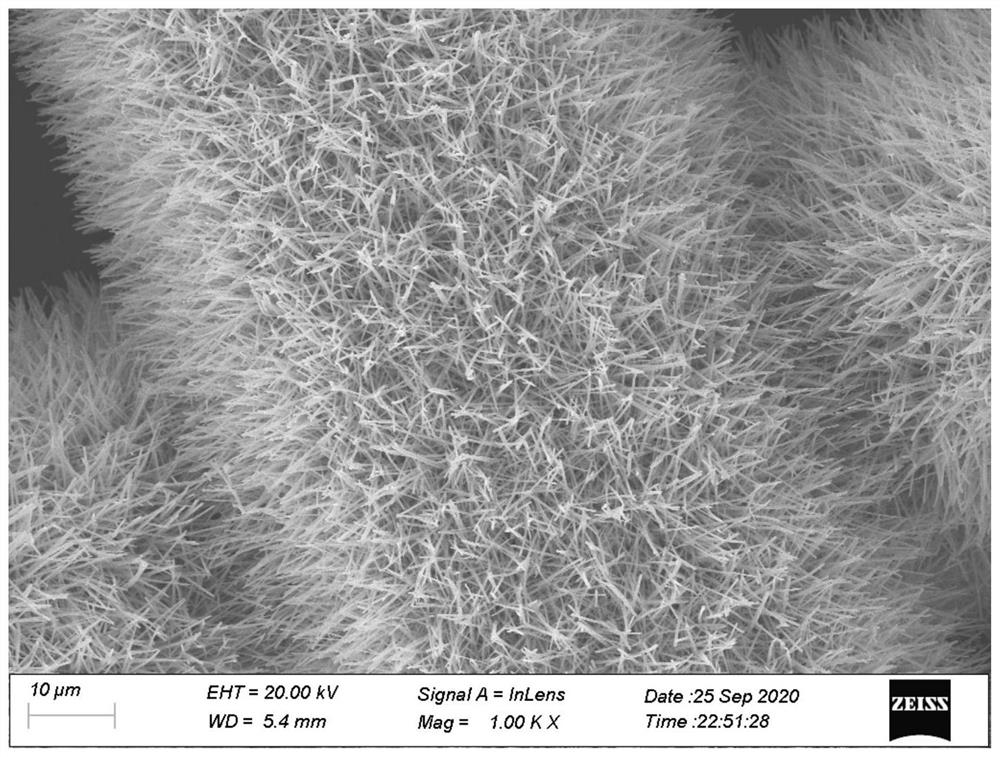

[0046] Cut the commercially available copper mesh with a mesh size of 200 to 3×4cm 2 Slices of different sizes were ultrasonically cleaned with absolute ethanol and deionized water for 5 min, respectively, and dried in an oven at 60°C for later use. Weigh 5.00g of sodium hydroxide and 1.14g of ammonium persulfate and dissolve them in 50mL of deionized water, stir to dissolve completely to obtain a mixed solution, place the pretreated copper mesh substrate in the mixed solution, take it out after 10min Dry it in an oven at 60°C for later use to obtain Cu(OH) 2 / CM, where Cu(OH) 2 It is a nanorod array structure with smooth surface.

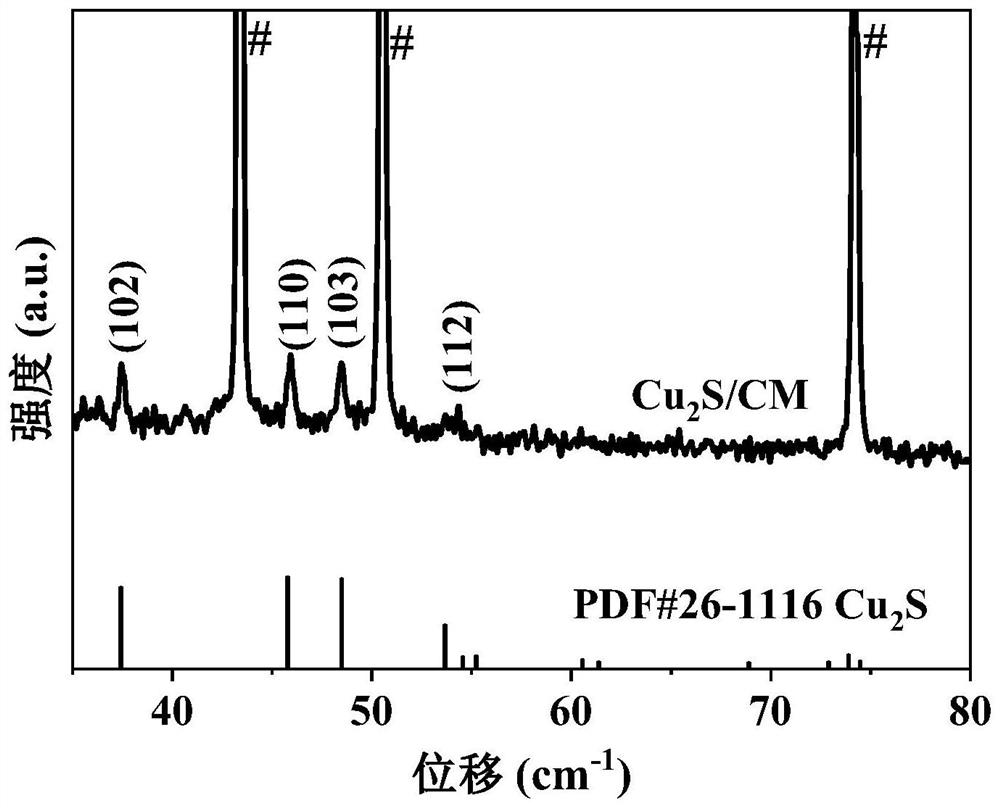

[0047] B. the Cu(OH) obtained in step A 2 / CM is placed in a porcelain boat, weigh 5.26g of thioacetamide and place it in a porcelain boat, place thioacetamide in the upstream of the nitrogen flow, Cu(OH) 2 / CM is placed downstream of the nitrogen flow, the set temperature is 150°C, and ...

Embodiment 2

[0050] A. Cut the commercially available copper mesh with a mesh size of 200 mesh to 3×4cm 2 Slices of different sizes were ultrasonically cleaned with absolute ethanol and deionized water for 5 min, respectively, and dried in an oven at 60°C for later use. 2.50 g of sodium hydroxide and 0.93 g of ammonium persulfate were weighed and dissolved in 50 mL of deionized water, and stirred to completely dissolve to obtain a mixed solution. Place the pretreated copper grid substrate in the mixed solution, take it out after 20 min, rinse it with deionized water, and dry it in an oven at 60°C for later use to obtain Cu(OH) 2 / CM, where Cu(OH) 2 It is a nanorod array structure with smooth surface.

[0051] B. the Cu(OH) obtained in step A 2 / CM is placed in a porcelain boat, weigh 5.26g of thioacetamide and place it in a porcelain boat, place thioacetamide in the upstream of the nitrogen flow, Cu(OH) 2 / CM is placed downstream of the nitrogen flow, the set temperature is 140°C, and ...

Embodiment 3

[0054] A. Cut the commercially available copper mesh with a mesh size of 200 mesh to 3×4cm 2 Slices of different sizes were ultrasonically cleaned with absolute ethanol and deionized water for 5 min, respectively, and dried in an oven at 60°C for later use. 4.0 g of sodium hydroxide and 1.0 g of ammonium persulfate were weighed and dissolved in 50 mL of deionized water, stirred to completely dissolve to obtain a mixed solution. Place the pretreated copper grid substrate in the mixed solution, take it out after 20 min, rinse it with deionized water, and dry it in an oven at 60°C for later use to obtain Cu(OH) 2 / CM, where Cu(OH)2 It is a nanorod array structure with smooth surface. .

[0055] B. the Cu(OH) obtained in step A 2 / CM is placed in a porcelain boat, weigh 5.26g of thioacetamide and place it in a porcelain boat, place thioacetamide in the upstream of the nitrogen flow, Cu(OH) 2 / CM is placed downstream of the nitrogen flow, at 1°C min -1 The heating rate was inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com