Double fluidized bed material circulation control system and control method

A technology of material circulation and double fluidized bed, which is applied in the manufacture of combustible gas, granular/powdered fuel gasification, petroleum industry, etc. Carrier amount control is difficult and other problems, to achieve the effect of reducing the difficulty of subsequent purification treatment, simple and reliable adjustment method, and improving pyrolysis efficiency and pyrolysis product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

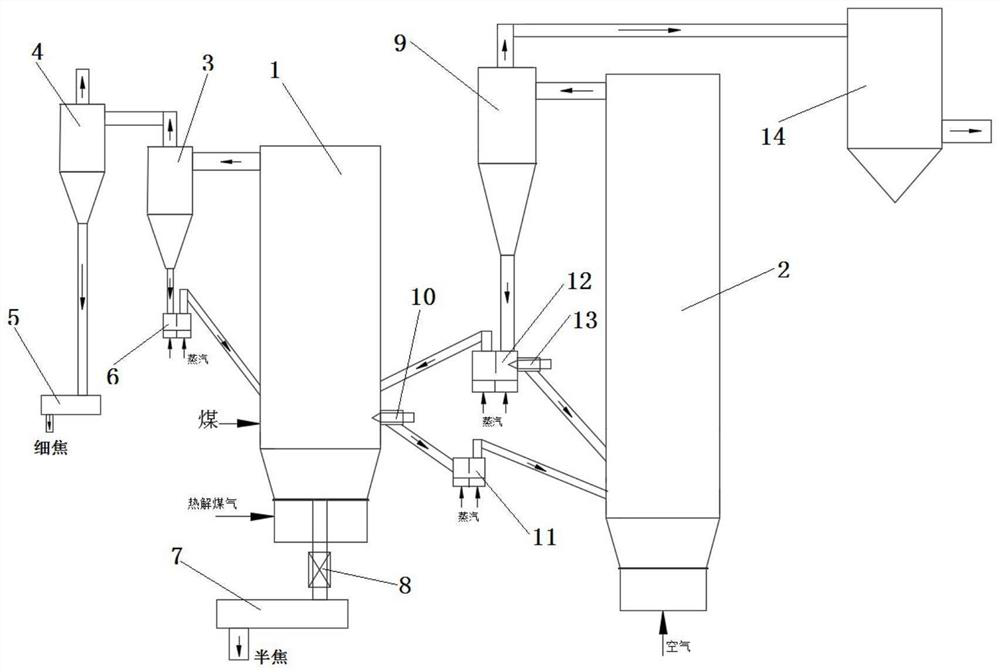

[0030] Such as figure 1 As shown, a dual fluidized bed material circulation control system includes a fluidized bed semi-coke heating furnace 2, a high temperature cyclone separator 9 and a fluidized bed pyrolysis furnace 1 connected in sequence.

[0031] The upper outlet of the fluidized bed semi-coke heating furnace 2 is connected with the upper inlet of the high temperature cyclone separator 9; The side of the first returner 12 is provided with a high-temperature cone valve 13, and the high-temperature cone valve 13 is connected to the first heating furnace inlet on the lower side wall of the fluidized bed semi-coke heating furnace 2 through the pipeline. Connected; the top outlet of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com