Bionic robotic fish for monitoring corrosion condition of underwater pile foundation of offshore wind plant

A technology for robotic fish and wind farms, applied in the field of bionic robotic fish, can solve the problems of affecting power generation efficiency, seabed, pile foundation or submarine cable defects, and high operation and maintenance management costs, so as to improve monitoring efficiency and accuracy, guarantee Power generation efficiency and safety, and the effect of reducing operation and maintenance management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

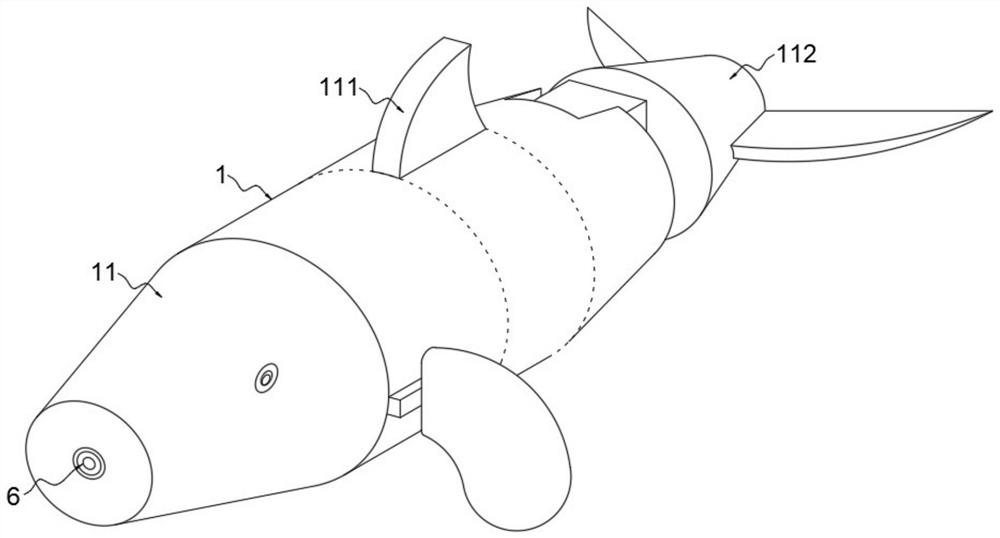

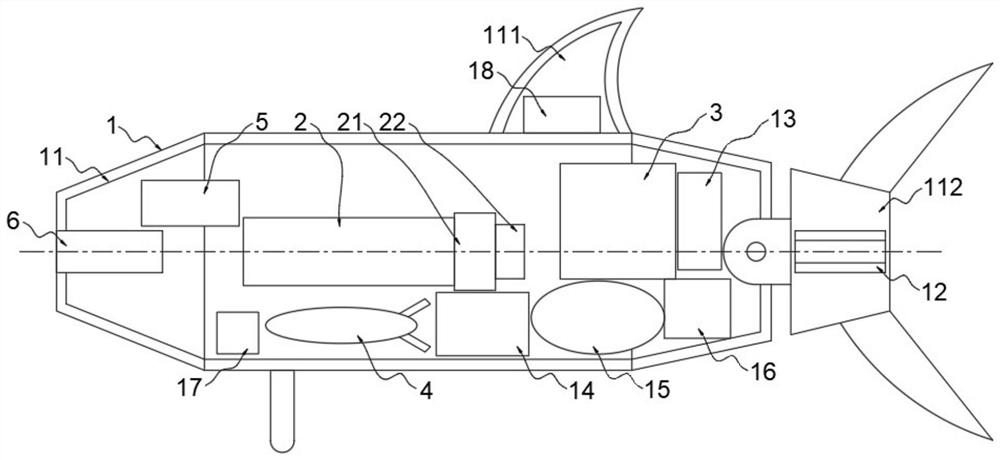

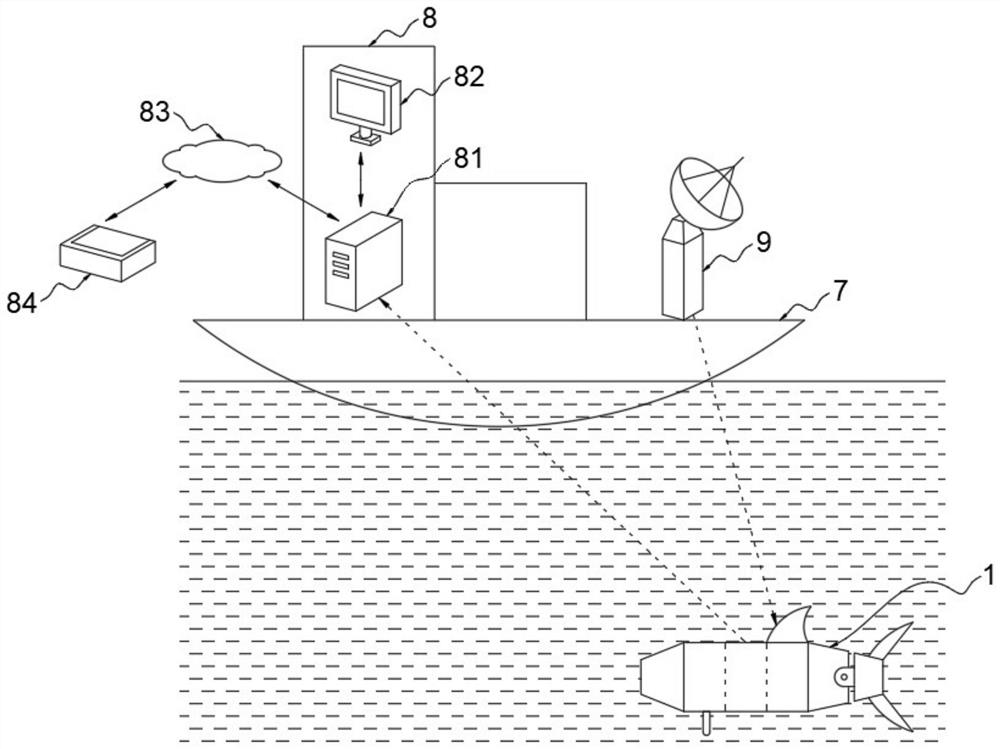

[0058] as Figure 1- Figure 3 As shown, the present embodiment provides a bionic machine fish for offshore wind farm underwater pile foundation corrosion monitoring, comprising a bionic machine fish body 1, the bionic machine fish body 1 including the main housing 11, the main housing 11 internal rules cloth provided with a power thruster 12, a controller 13, a buoyancy regulator 14, a sinking airbag 15, an air compressor 16, a depth sensor 17 and a satellite navigation device 18, the bionic machine fish body 1 also has a regular cloth with a processor 2, a power manager 3, a multi-beam detection sonar 4, Sound velocity profiler 5 and front-looking sonar 6, bionic machine fish body 1 is equipped with a measurement ship 7, the measurement ship 7 is equipped with a main control room 8 and a satellite reference / rover station 9.

[0059] In the present embodiment, the main housing 11 is provided with a fin empty shell 111 at the tip, the tail of the main housing 11 is articulated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com