Consumable replaceable 3D printer

A technology of 3D printers and consumables, applied in the field of 3D printing, can solve the problems of single color of printed products and limit the development of 3D printing, and achieve the effect of position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

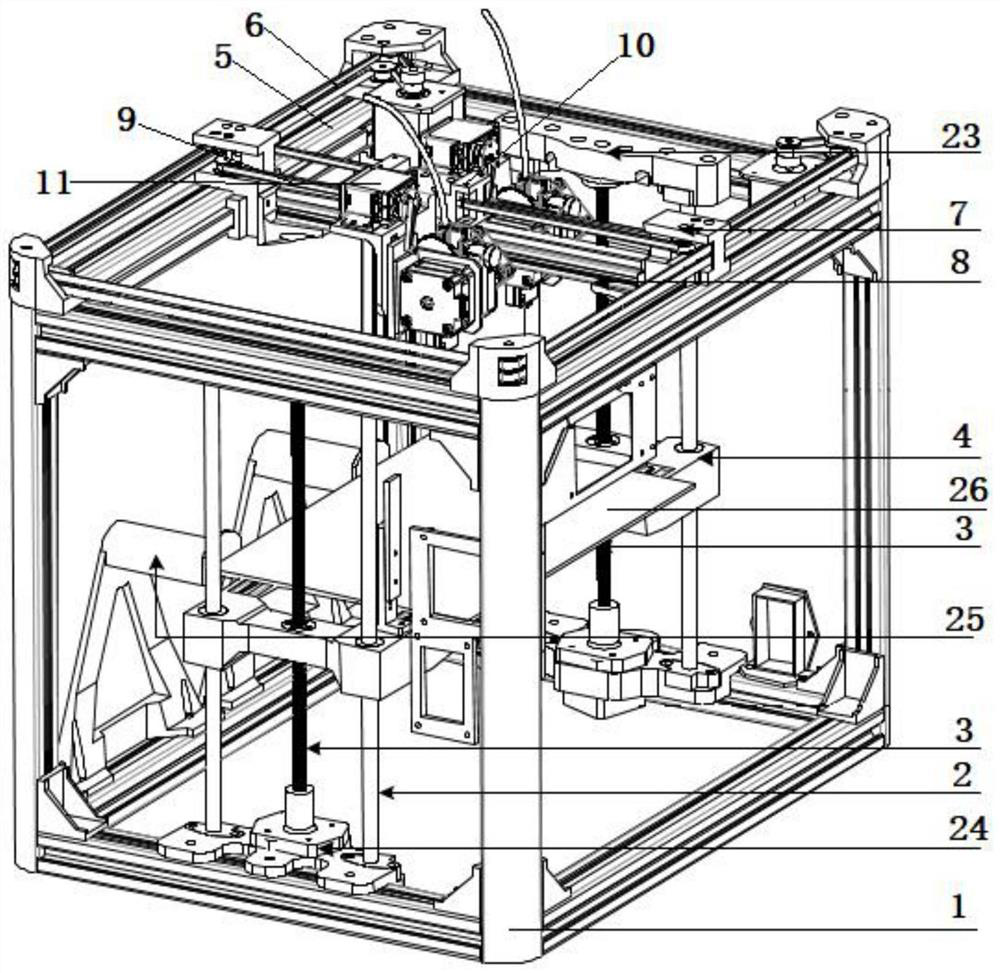

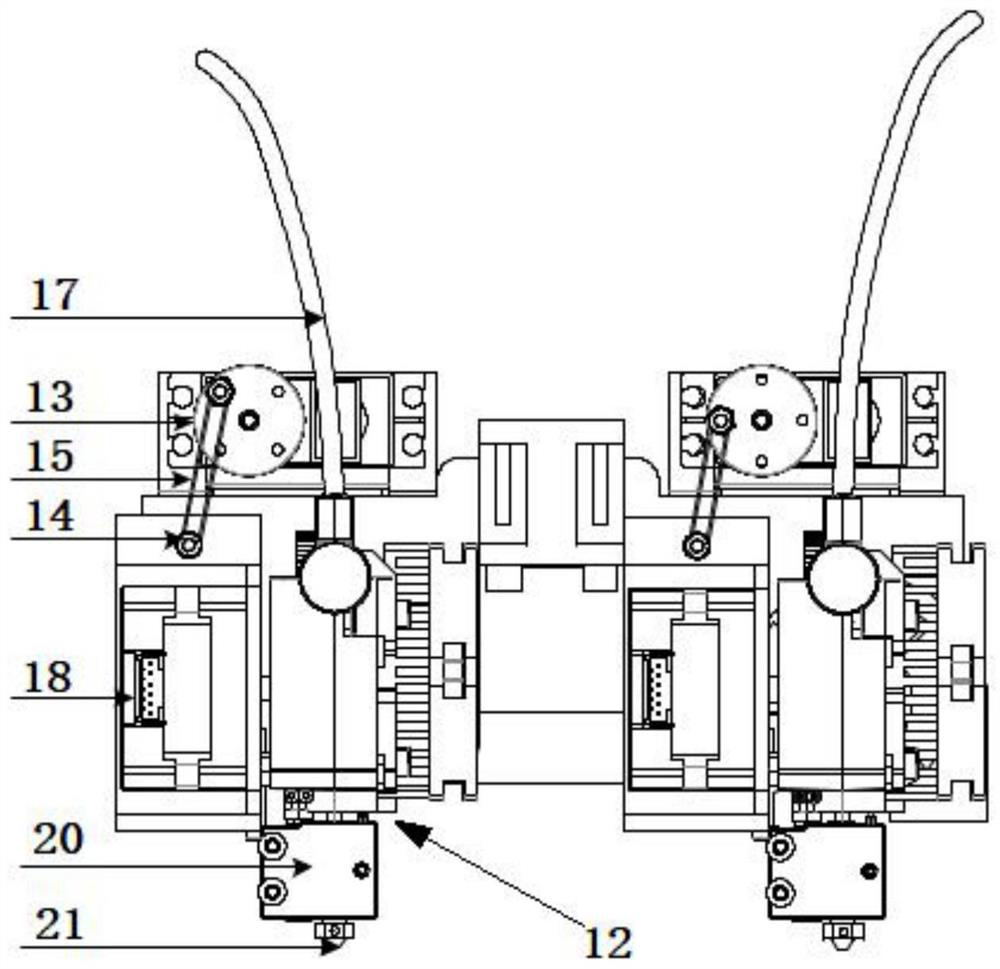

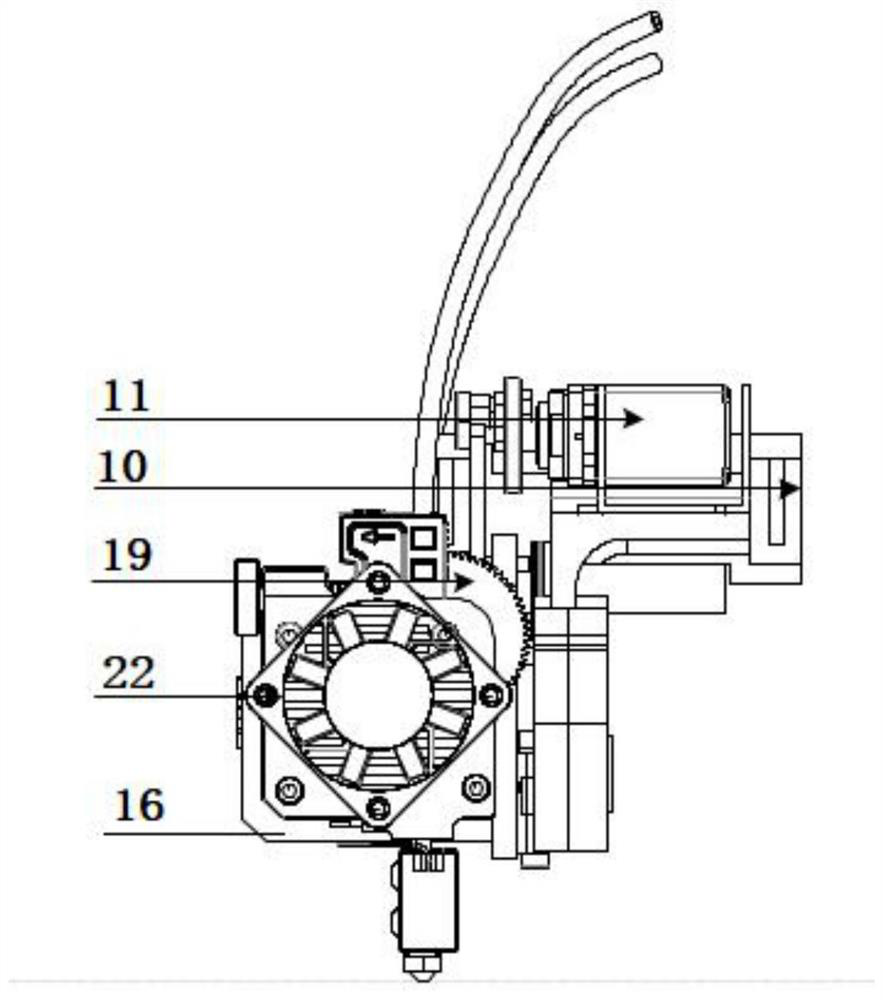

[0018] Embodiment: a kind of consumable material can change 3D printer, as attached figure 1 As shown, including the frame 1, both sides of the frame 1 are provided with vertically arranged Z-axis guide rods 2, one side of the Z-axis guide rod 2 is provided with a screw rod 3 connected to the motor, and the Z-axis guide rods on both sides are provided with The rod 2 is jointly provided with a heating bed support table 4 threadedly matched with the screw rod 3; the top of the frame 1 is provided with a symmetrically arranged X-axis guide rail 5 and an X-axis closed transmission belt 6 connected to the motor, and the X-axis closed transmission belt 6 is provided with an X-axis slider 7 slidingly connected to the X-axis guide rail 5, and a Y-axis guide rail 8 is provided on the two X-axis sliders 7. The top of the frame 1 is also provided with a Y-axis closed port connected to the motor. Drive belt 9, the Y-axis closed drive belt 9 is provided with a connecting seat 10 that is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com