Vibration exciter and using method thereof

A technology of exciter and exciter shaft is applied in the direction of fluid using vibration, which can solve the problems of cumbersome process and large workload, and achieve the effects of constant value, improved work efficiency and high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

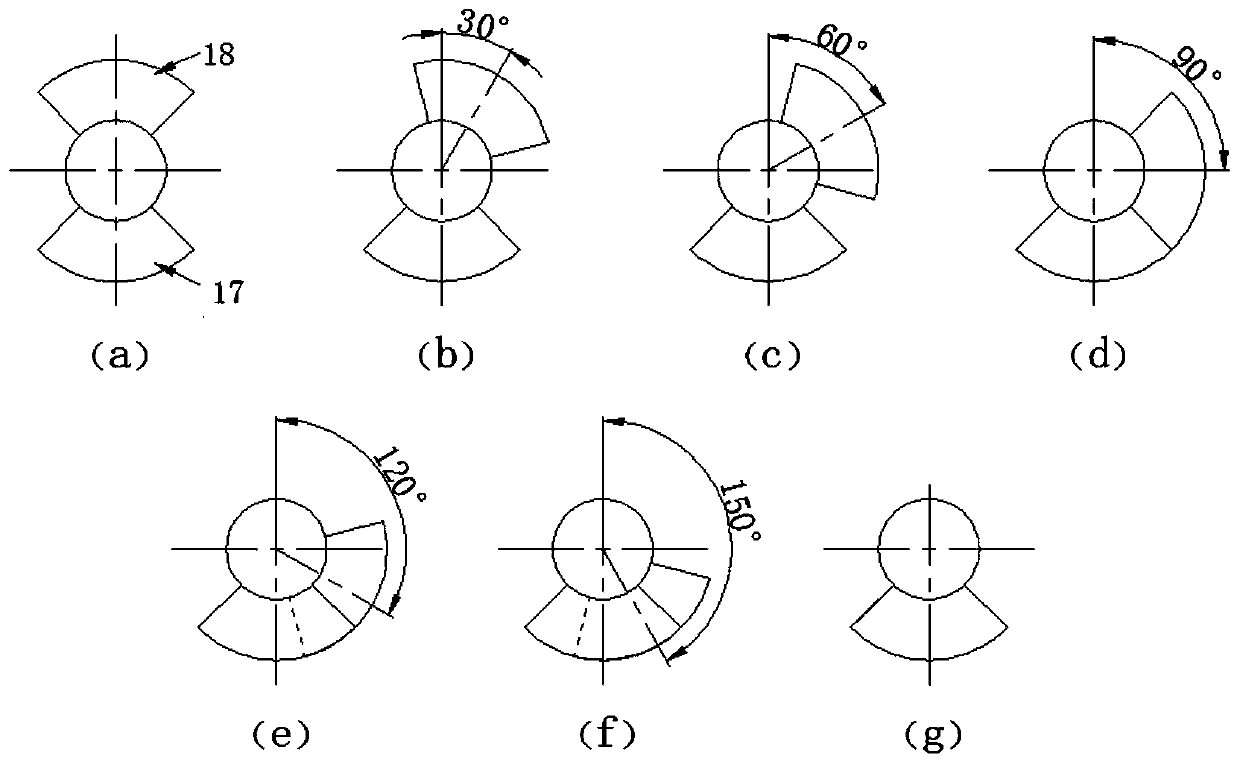

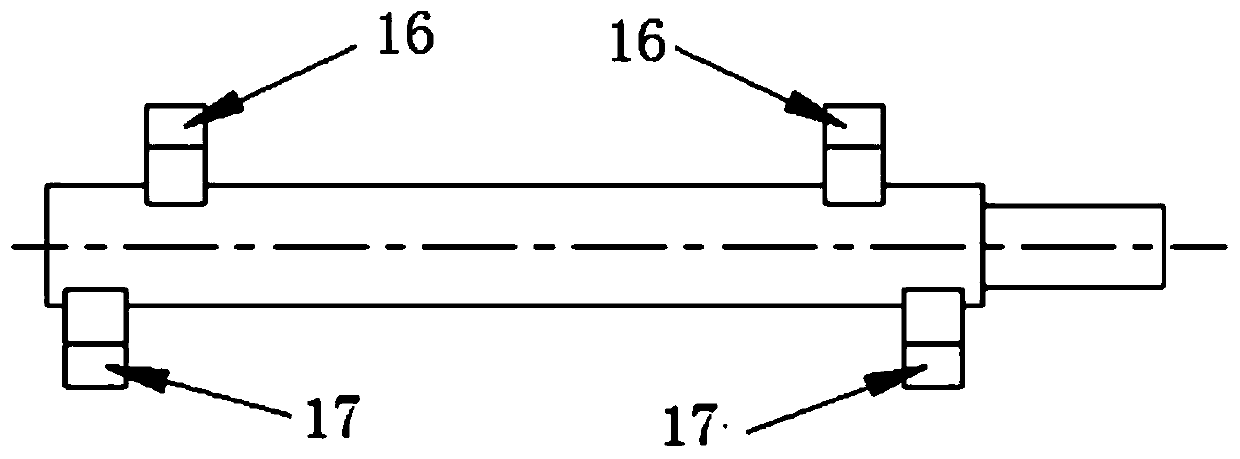

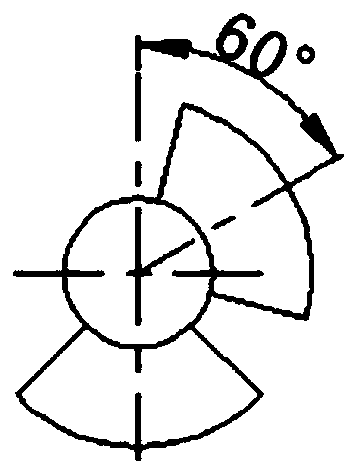

[0041] like Figure 4~8As shown, the vibrator in the present invention includes an excitation shaft and an eccentric mass. The excitation shaft includes a central rotating shaft 12 and an outer ring rotating shaft 13. An axial through hole is arranged in the outer ring rotating shaft 13, and the central rotating shaft 12 is placed in the outer ring. In the rotating shaft 13, the central rotating shaft 12 and the outer ring rotating shaft 13 are arranged coaxially. This shaft will be replaced by "axis 9" in the following expressions. Two first eccentric blocks 10 are arranged on the side wall of the central rotating shaft 12, and the two first The eccentric block 10 is arranged on the same side of the axis 9; two second ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com