Rubber mixing and extruding device

An extrusion device and rubber technology, which is applied in the field of rubber extrusion molding equipment, can solve problems such as safety hazards, explosions, and sulfur toxicity, and achieve the effects of enhancing conveying capacity, reducing direct damage, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

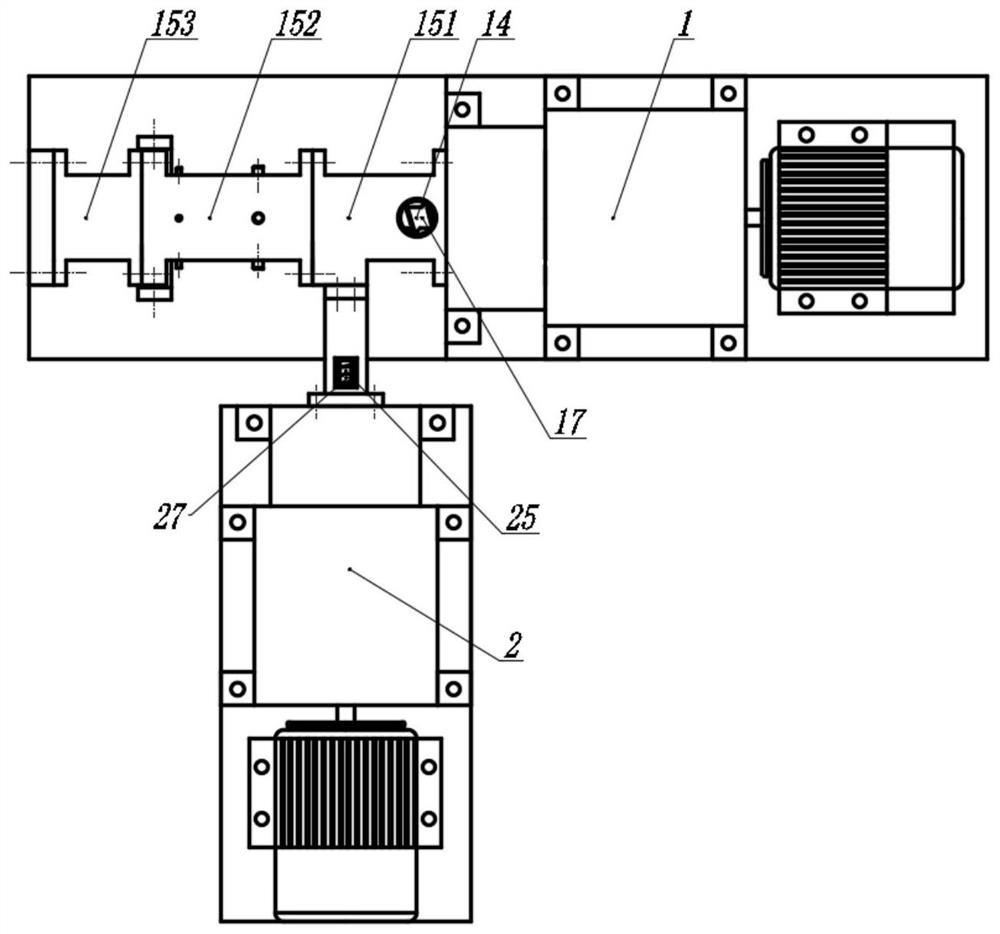

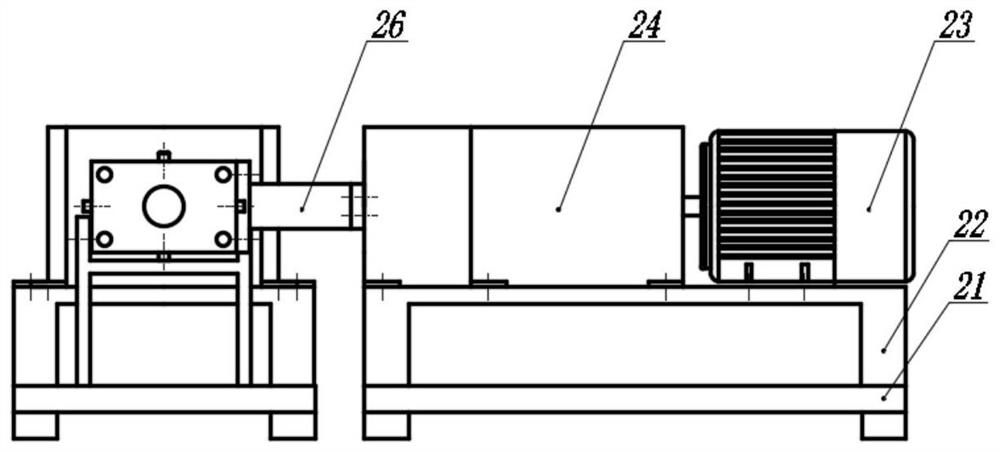

[0048] Such as Figure 1-6 As shown, a rubber mixing extrusion device involved in this embodiment is composed of a main extruder 1 and an auxiliary extruder 2 connected at right angles, and the main extruder 1 uniformly compacts the compounded rubber and the auxiliary extruder 2 The vulcanizing agent and accelerator or sulfur-containing masterbatch are fully mixed and mixed at low temperature.

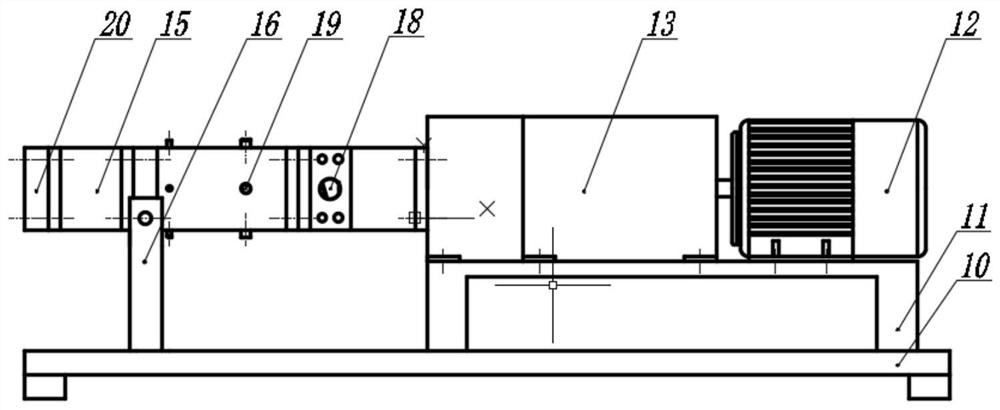

[0049] The main structure of the main extruder 1 involved in this embodiment includes a main mounting seat 10, a main base 11, a main motor 12, a main speed reducer 13, a main screw 14, a main barrel 15, a main frame 16, a main feeding port 17, Connection port 18, pin 19 and host head 20;

[0050]The upper surface of the main mounting base 10 is provided with a main base 11, the main base 11 is provided with a main motor 12 and a final reducer 13, the output end of the main motor 12 is connected with the input end of the final reducer 13, and the final drive 13 The output end of the ...

Embodiment 2

[0068] Such as Figure 7-8 As shown, as a preferred embodiment of the present invention, if there are reinforcing fillers such as short fibers in the rubber compound, the transmission pressurization section 1405 is replaced by a pressurization replacement section 14051, and the transmission decompression section 1407 is replaced by a decompression Replace paragraph 14071.

[0069] The pressure replacement section 14051 and the decompression replacement section 14071 change the thread shape of the original transfer section from trapezoid to triangle, so that the shear force of the rubber between the screw edge and the inner wall of the barrel increases, and the material shear and dispersion are strong. , Mixing evenly, can fully combine the reinforcing filler with the rubber-based material.

[0070] Combined with the anti-mixing section 1408, the material and the reinforcing filler are mixed, stretched and sheared longitudinally and transversely under the action of positive an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com