Nano-silver coated micron copper soldering paste and preparation method thereof

A technology of micron copper and silver-clad copper, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high cost of nano-solder, harsh sintering conditions, complex sintering conditions, etc., to overcome the difficulty of storage and oxidation resistance Good, the effect of overcoming the high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

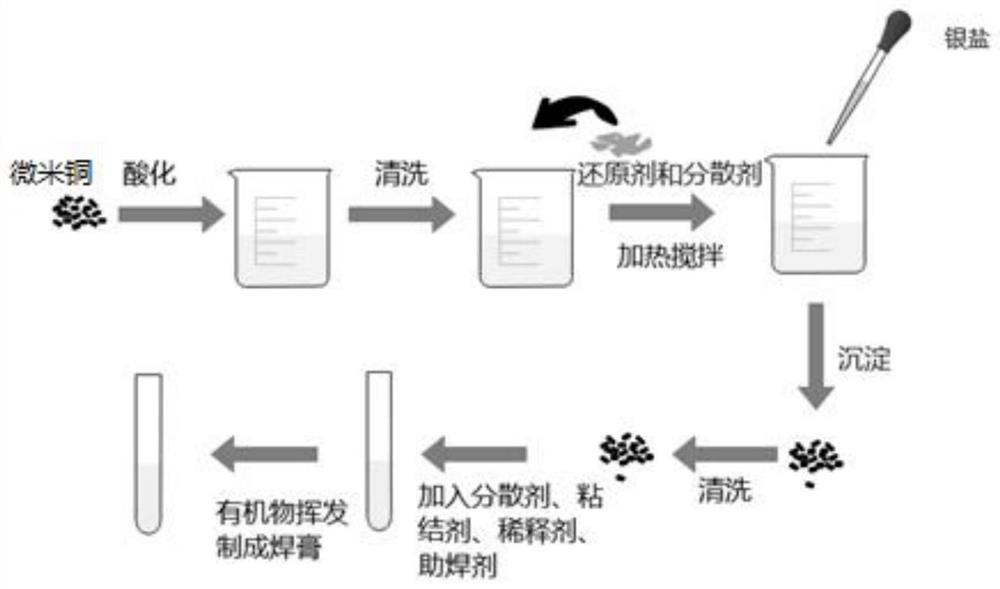

[0040] The preparation of nano-silver coated micron copper solder paste comprises the following steps:

[0041] (1) Put 5g of micron copper particles into a beaker, add 50ml of dilute nitric acid with a mass fraction of 5% to acidify, ultrasonically oscillate for 5 minutes, and use a high-speed centrifuge to separate liquid and solid at 4000r / min. The obtained copper particles are deionized Washing with water three times to obtain product A, that is, micron copper particles after acidification.

[0042](2) Put the product A obtained in step (1) into a beaker, add 300ml of deionized water, add 4g of ascorbic acid, 4g of polyvinylpyrrolidone (PVP), heat in a water bath at 40°C and stir to dissolve, and dropwise add a concentration of 0.3mol / L Silver nitrate solution 60mL, keep stirring during the dropwise addition, keep the stirring rate of 300r / min after the dropwise addition is completed, continue to react in a water bath at 40°C for 1h, after the reaction is completed, use a ...

Embodiment 2

[0046] The preparation of nano-silver coating micron copper solder paste, the steps are as follows:

[0047] (1) Put 10g of micron copper particles into a beaker, acidify with 100ml of dilute sulfuric acid with a mass fraction of 8%, ultrasonically oscillate for 8 minutes, and use a high-speed centrifuge to separate liquid and solid at 4000r / min. The obtained copper particles are deionized Washed with water three times to obtain product A.

[0048] (2) Put the product A into a beaker, add 300ml of deionized water, add 6g of hydrazine hydrate, 2g of cetyltrimethylammonium bromide, heat in a water bath at 50°C and stir to dissolve, add dropwise 0.4mol / L Silver nitrate solution 80mL, keep stirring during the dropwise addition, keep the stirring rate of 400r / min after the dropwise addition is completed, continue to react in a water bath at 50°C for 2h, after the reaction is completed, use a high-speed centrifuge at 3000r / min for liquid-solid After separation, the obtained precipi...

Embodiment 3

[0051] The preparation of nano-silver coated micron copper solder paste comprises the following steps:

[0052] (1) Put 15g of micron copper particles into a beaker, acidify with 150ml of dilute nitric acid with a mass fraction of 5%, ultrasonically oscillate for 10 minutes, and use a high-speed centrifuge to perform liquid-solid separation under the condition of 4000r / min, and the obtained copper particles are deionized Washed with water three times to obtain product A.

[0053] (2) Put product A into a beaker, add 300ml of deionized water, add 8g of sodium borohydride, 24g of PVP, heat at 70°C and stir to dissolve, add dropwise 1100mL of silver nitrate solution with a concentration of 1mol / L, and continue to Stir, keep the stirring rate of 500r / min after the dropwise addition is completed, and continue to react in a 70°C water bath for 3h. After the reaction is completed, use a high-speed centrifuge to separate the liquid from the solid at 3000r / min. Alternately washing and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com