Numerical-control full-automatic positioning and forming welding machine for aluminum-clad wooden doors or windows

An aluminum-clad, fully automatic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of physical hazards for operators, failure to meet mass production, and difficulty in controlling weld formation, and achieve overall The appearance is beautiful, the effect of overcoming water ingress and moisture in wood, and the weld seam is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the structural principles of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

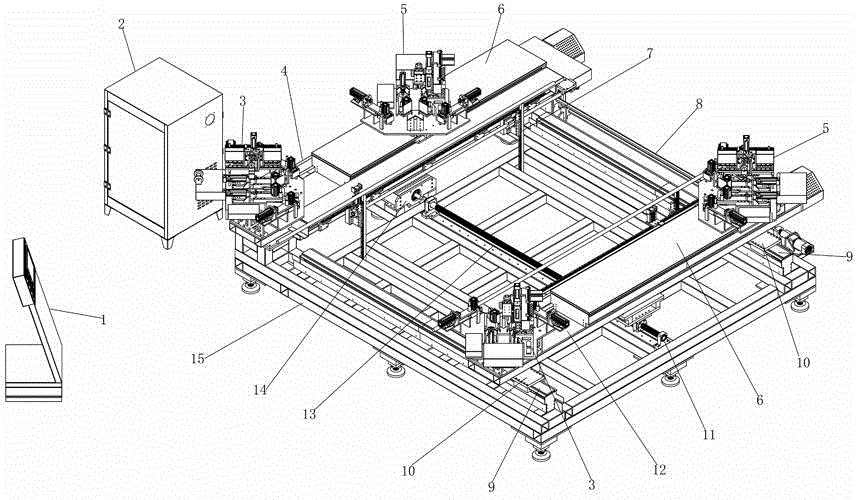

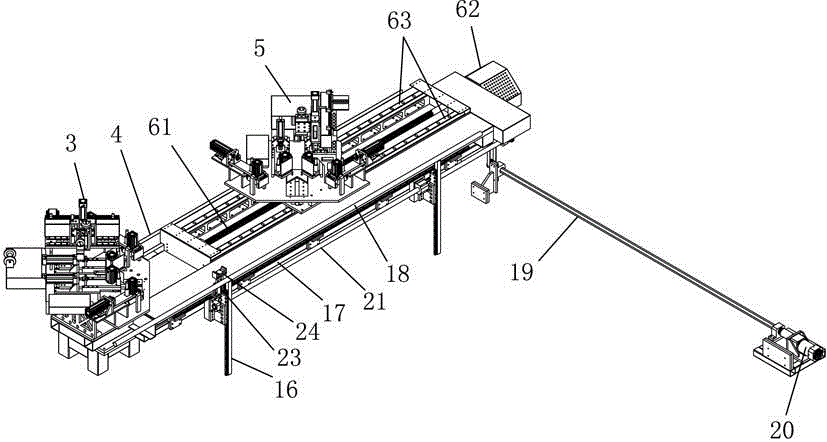

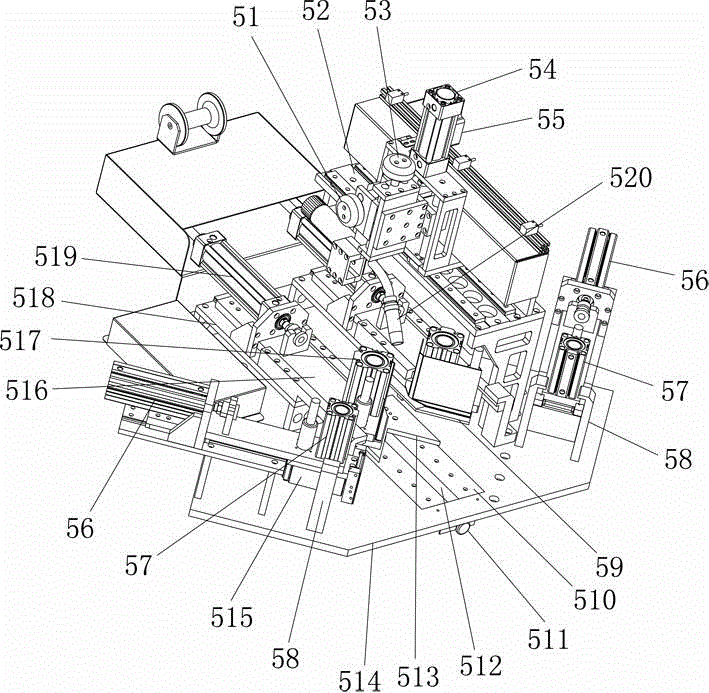

[0031] Such as figure 1 , figure 2 , image 3 As shown, a numerically controlled automatic aluminum-clad wood door and window positioning and forming welding machine includes a control system and an underframe 15. The underframe 15 is provided with a fixed frame 4, two horizontal guide rails 9 arranged in parallel, and a moving Frame 12 and transverse driving mechanism, described fixed frame 4 and mobile frame 12 are respectively arranged on the transverse both sides of underframe 15, and two transverse guide rails 9 are respectively arranged on the longitudinal both sides of underframe 15, two transverse A transverse drive mechanism is arranged between the guide rails 9, and a mobile frame 12 is provided on the two transverse guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com