Inclined building hoist cage

A construction hoist, tilting technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve problems such as safety hazards, tilting cages, and inability to guarantee the stability of cages, etc., to achieve stable operation and enhanced connections Stability, avoiding the effect of poor running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

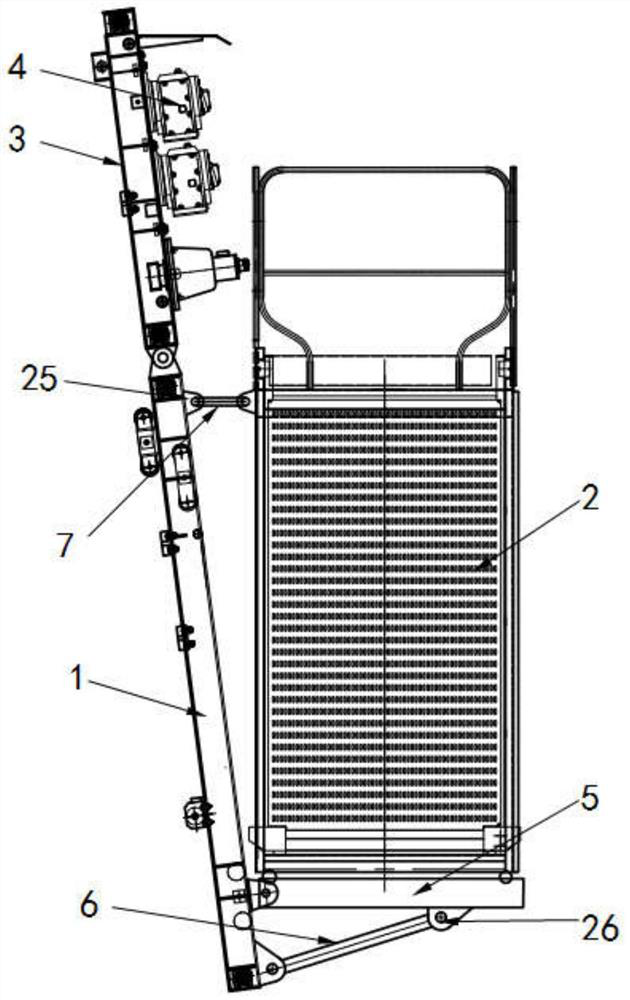

[0038] Such as figure 1 As shown, this embodiment provides an inclined construction hoist cage, including a cage transmission frame 1 , a cage body 2 , a driving frame 3 and a driving device 4 .

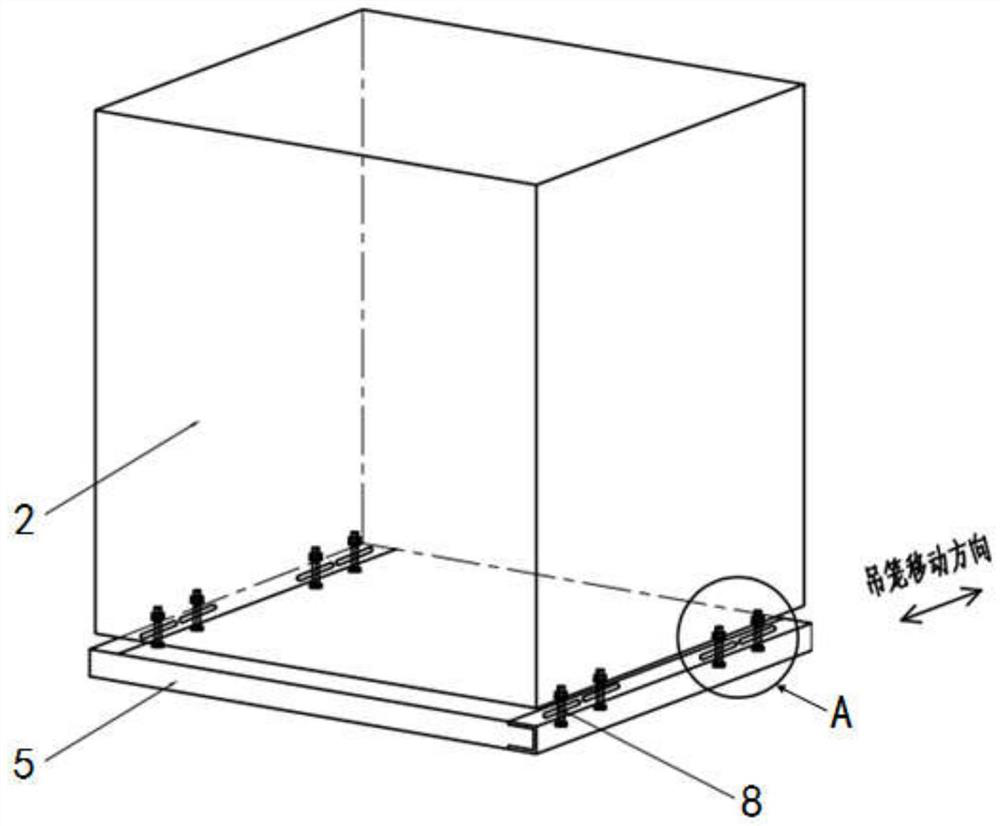

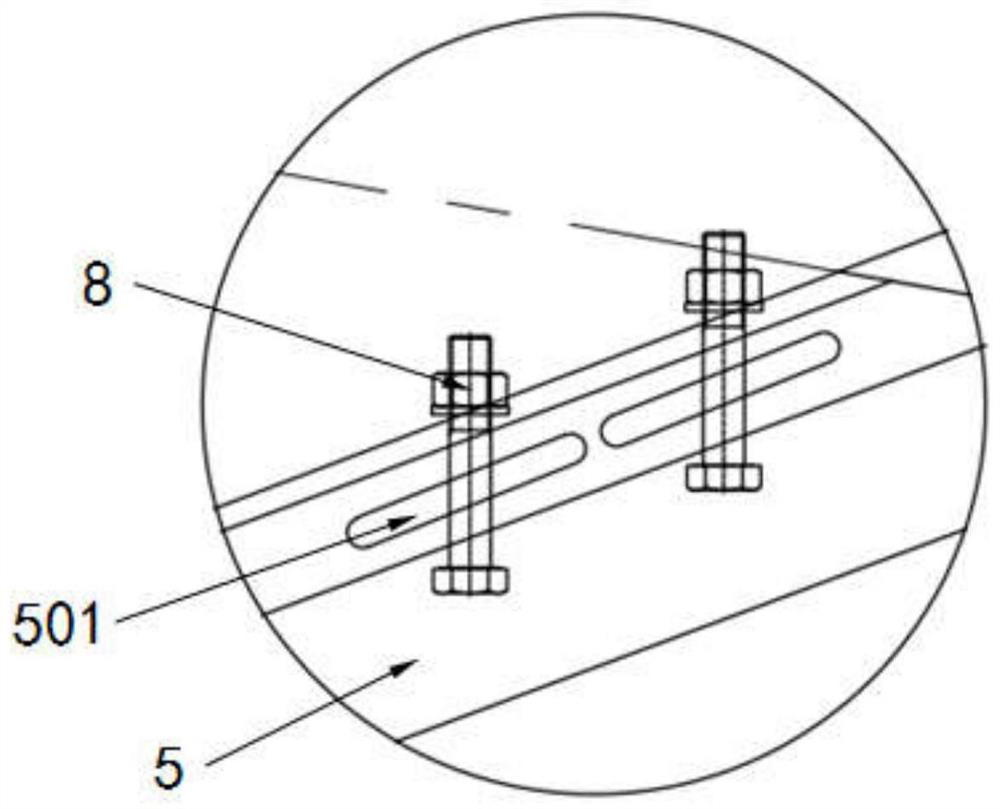

[0039] Such as Figure 1-3 As shown, the cage body 2 is installed on the load-bearing platform 5, the cage body 2 and the load-bearing platform 5 are connected by fixing bolts 8, and the load-bearing platform 5 is provided with bolt holes 501 for installing the fixing bolts 8, and the bolt holes 501 are elongated And extend along the direction of the cage body 2 to the cage transmission frame 1, ensure that the cage body 2 can be adjusted horizontally toward the direction of the guide rail frame, ensure that the center of gravity of the cage body 2 is close to the center of the guide rail frame, thereby improving the mechanical properties of the whole machine.

[0040] Such as figure 1 As shown, the load-bearing platform 5 and the cage drive frame 1 are hinged by a pin, so that the...

Embodiment 2

[0049] This embodiment provides an inclined construction hoist cage, including the structure in Embodiment 1.

[0050] Such as Figure 12 with 13 As shown, the structures of the first side roller 9 and the second side roller 19 are the same and are supported at both ends. The position where the first side roller 9 is installed on the cage transmission frame 1 is provided with a first fixed lug 903 and a second fixed lug 908 oppositely arranged; the first side roller 9 includes a support bolt 901, an eccentric shaft 904, a shaft sleeve 906 and The side roller assembly 905, the side roller assembly 905 is installed outside the eccentric shaft 904, one end of the eccentric shaft 904 is docked with the sleeve 906 and sleeved on the outside of the support bolt 901, the other end of the eccentric shaft 904 is clamped with the first fixed ear plate 903, The other end of the bushing 906 is inserted into the inner side of the second fixing plate 908 , and the supporting bolt 901 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com