Rare earth complex agricultural light conversion film and preparation method thereof

A rare earth complex and light-converting film technology, applied in the field of agricultural film materials, can solve the problems of unstable quality and low luminous efficiency of the light-converting film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

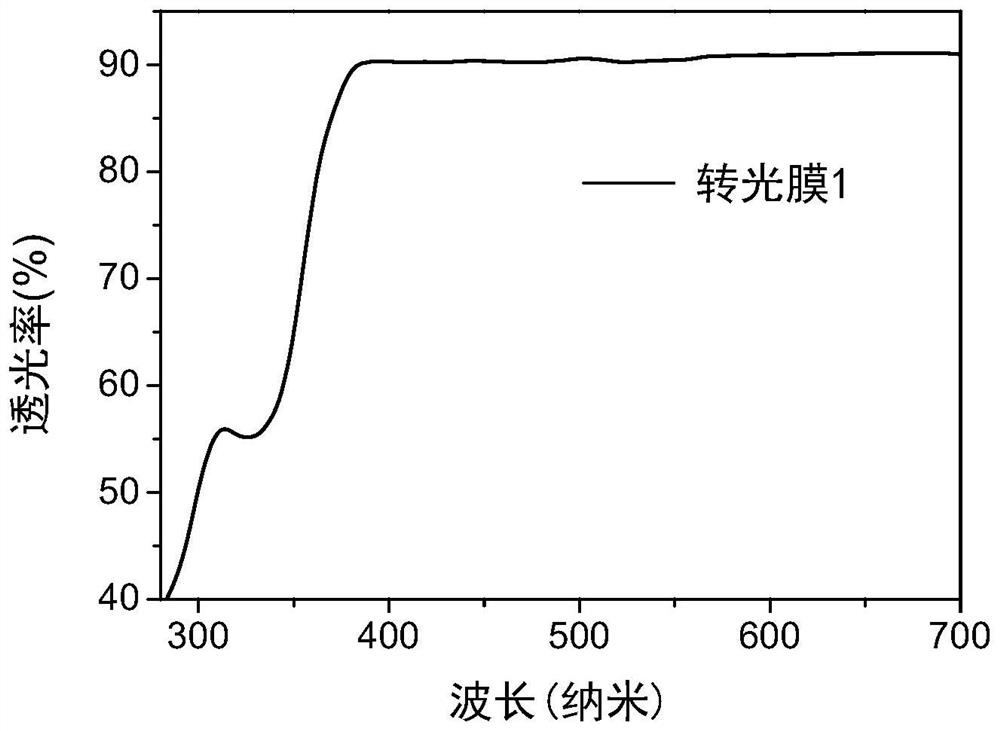

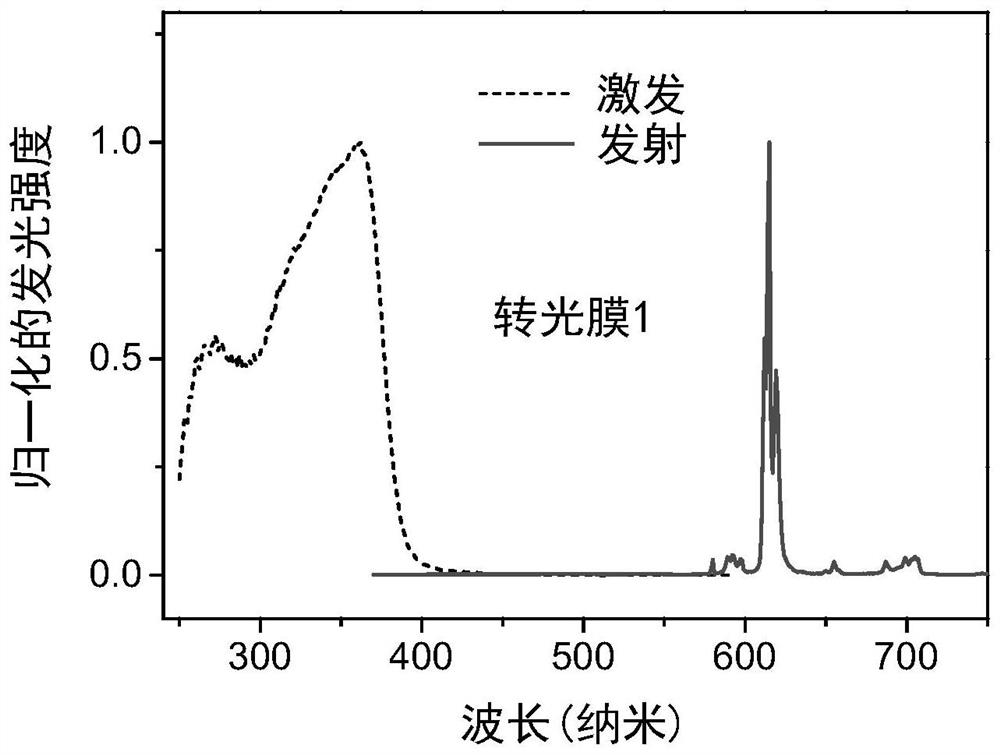

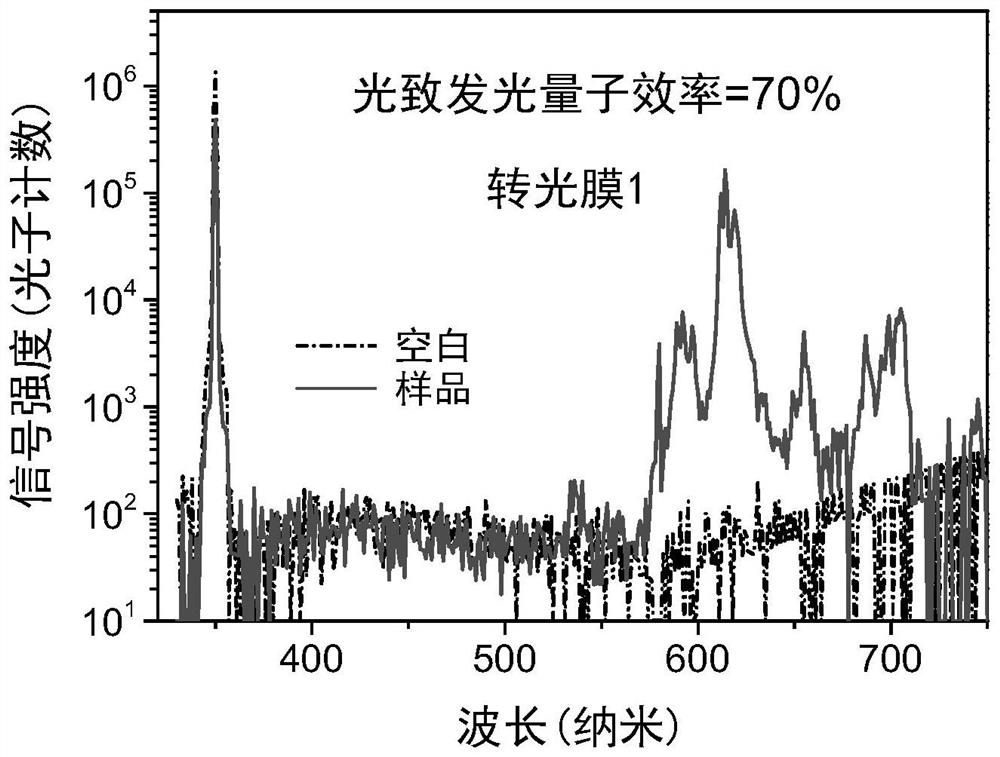

[0041] A three-layer co-extruded coating type light conversion film, including an inner layer (mechanical structure layer), a middle layer (light conversion layer), and an outer layer (coating carrier layer), each layer has a thickness of 30 microns, a total of 90 microns. The inner and outer layers contain 10 parts of long-life aging masterbatch and 90 parts of base material; the middle light conversion layer contains 15 parts of alkaline light conversion masterbatch, 10 parts of single anti-aging masterbatch and 75 parts of base material.

[0042] The base material is one, two or three mixtures of low-density polyethylene (LDPE), metallocene linear low-density polyethylene (MLLDPE), and ethylene-vinyl acetate copolymer (EVA).

[0043] Longevity aging masterbatch is made by mixing and granulating 5% light stabilizer 944, 1.5% antioxidant 1010, 1% antioxidant 168, 1% erucamide slip agent and 91.5% polyethylene of. Longevity aging masterbatch is granulated by twin-screw proces...

Embodiment 2

[0052] A five-layer co-extruded coating type light conversion film, comprising an inner layer (mechanical structure layer), a second inner layer (mechanical structure layer), a middle layer (light conversion layer), a second outer layer (insulation layer), an outer layer (coating layer) Covering the carrier layer), the thickness of each layer is 18 microns, a total of 90 microns. The inner and outer layers contain 10 parts of longevity aging masterbatch and 90 parts of base material; the sub-inner layer and sub-outer layer contain 10 parts of single anti-aging masterbatch, 5 parts of thermal insulation masterbatch, and 85 parts of base material; the middle layer contains 25 parts of alkaline light conversion masterbatch, 10 parts of single anti-aging masterbatch, 65 parts of base material.

[0053] The base material is one, two or three mixtures of low-density polyethylene (LDPE), metallocene linear low-density polyethylene (MLLDPE), and ethylene-vinyl acetate copolymer (EVA)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com