Battery assembly of CTP configuration, electric vehicle and design method

A battery assembly and configuration technology, applied in the automotive field, can solve problems such as the inability to achieve integration and the complexity of battery components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

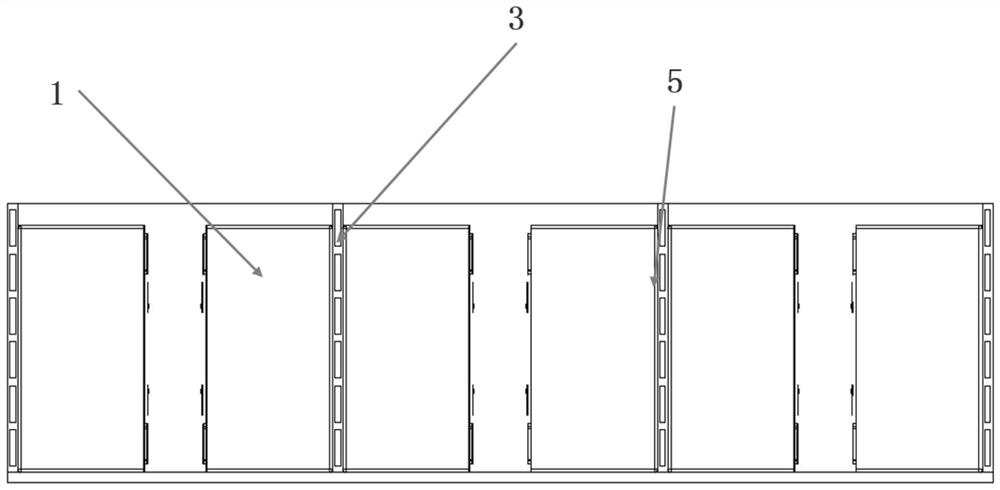

[0048] refer to figure 1 and figure 2 , the present embodiment provides a CTP-shaped battery assembly, including a battery case and a battery pack disposed in the battery case.

[0049] The battery pack includes a battery module 1 in a CTP configuration, a box beam 2 , a water cooling plate 3 , a box front plate 4 , a thermally conductive structural adhesive 5 , a box rear end plate 6 and a water pipe joint 7 .

[0050] The battery box includes a box front end plate 4, a box rear end plate 6, a box bottom plate and a box side plate.

[0051] The battery module 1 in the CTP configuration is arranged lying on its side, and the bottom is fixed on the water-cooled plate 3 through the heat-conducting structural adhesive 5 to realize the fixed installation of the battery module 1 in the CTP configuration. The adhesive bonding strength of the thermally conductive structural adhesive 5 is ≥4MPa and the thermal conductivity is ≥0.2W / m*k), which can not only ensure the heat conductio...

Embodiment 2

[0063] This embodiment provides an electric vehicle, including a CTP-configured battery assembly in Embodiment 1. The electric vehicle adopts a battery assembly with a CTP configuration in the embodiment. The battery unit is laid on its side and the water-cooled plate is fixedly arranged to realize the integration of the water-cooled plate and the side plate of the box body. In this case, the upper case of the battery will not be damaged, effectively delaying thermal runaway, and the water-cooled plate assembly 3 forms a closed thermal management coolant flow path circuit with the flow channel structure inside the rear end plate 6 of the case and the front end plate 4 of the case. The external connection of the water pipe joint 7 can realize the separation of dry and wet inside the battery pack. The design of no water pipe improves the assembly performance, reduces the risk of leakage caused by the water pipe conversion joint, and solves the problem that the existing battery co...

Embodiment 3

[0065] A design method for a CTP-configured battery assembly, for designing a CTP-configured battery assembly, comprising the following steps:

[0066] Step 1. Take the layout boundary and performance requirements of the battery pack as design input;

[0067] Step 2. Determine the number of battery modules according to the layout boundary of the battery pack and the performance requirements, and further confirm the number of battery modules 1 in the CTP configuration;

[0068] Step 3. Determine the number of water-cooled plates 3 based on the number of battery modules 1 in CTP configuration. Among them, the water-cooled plates integrated with the side panels of the box are arranged with one battery module 1 in CTP configuration, and the water-cooled plates 3 in the middle are arranged with two A battery module 1 in a CTP configuration;

[0069] Step 4. Determine the position and thickness of the box beam 2 by the number of battery modules 1 in the CTP configuration, the numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com