Laser shaping optical fiber and preparation method and application thereof

A laser shaping and optical fiber technology, applied in cladding optical fiber, optical waveguide light guide, glass manufacturing equipment, etc., can solve the problems of poor batch consistency, unstable laser shaping effect, high defective rate, etc., to improve consistency and improve Homogenization effect, effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The invention also discloses a method for preparing a laser shaped optical fiber, which includes the following steps:

[0057] (1) On the base rod having a circular cross-section for forming the fiber core, a cold working process is used to form first and second through holes symmetrical to the center of the base rod; when the base rod is circular , the processing is the most convenient, especially the positioning of the subsequent punching step, so when the fiber core is circular, its base rod can only be used to form a circular core rod, or it can be used to form a fiber core and at least A base rod with a circular cross-section for part of the cladding; when the optical fiber is a non-circular core, it is preferred to use a base rod with a circular cross-section for forming the core and at least part of the cladding, for example When the core is designed to be non-circular, the shaped mandrel is nested and sintered in advance with the liner used to form at least part...

Embodiment 1

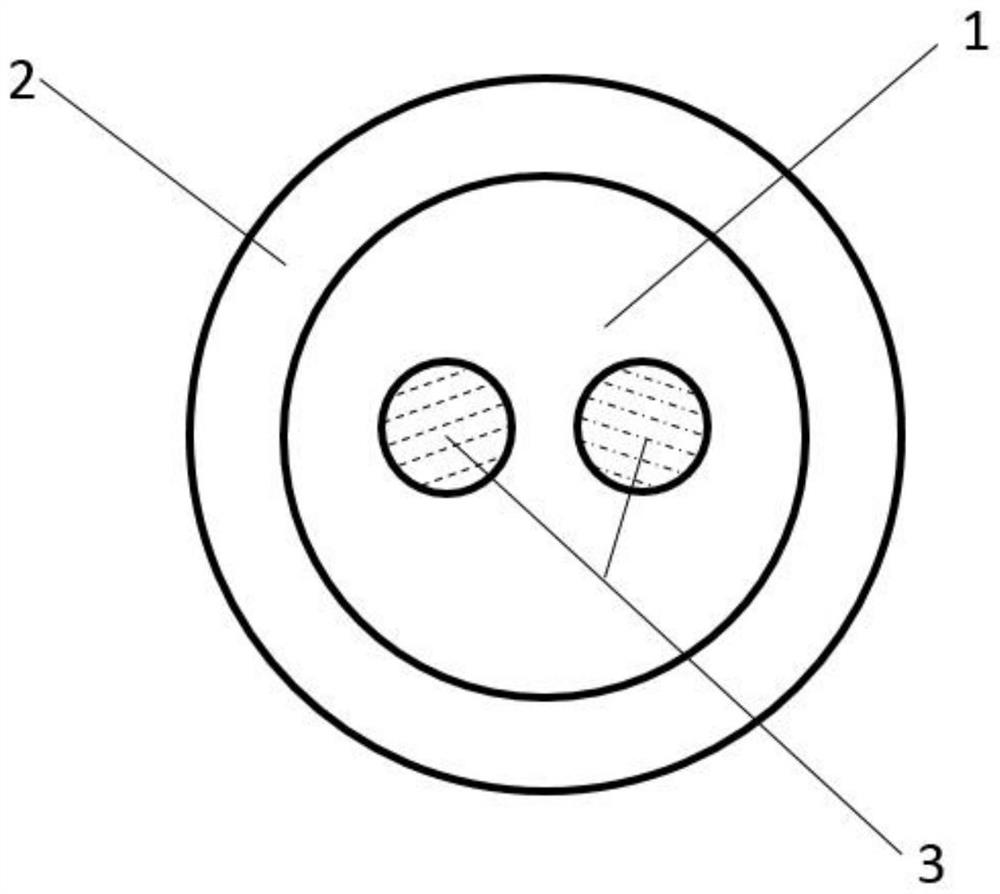

[0070] A laser shaping optical fiber is a multimode optical fiber, and its glass part with a circular cross section includes: a core and a cladding from the inside to the outside; the structure is as figure 1 Shown:

[0071] The core is circular, and the diameter of the circular cross-section of the circular core is 200 μm. The geometric central axis of the core or the central axis of the core precursor circle coincides with the geometric central axis of the fiber or is laterally offset by 5 μm.

[0072] The fiber core includes first and second doped regions that are symmetrical about the geometric center of the fiber core; the cross section of the doped region is circular, and the distance between the first and the second doped region is 45 μm; the first The total area of the two doped regions and the second one accounts for 20% of the total area of the core.

[0073] The first doped region and the second doped region have different refractive index distributions. The i...

Embodiment 2

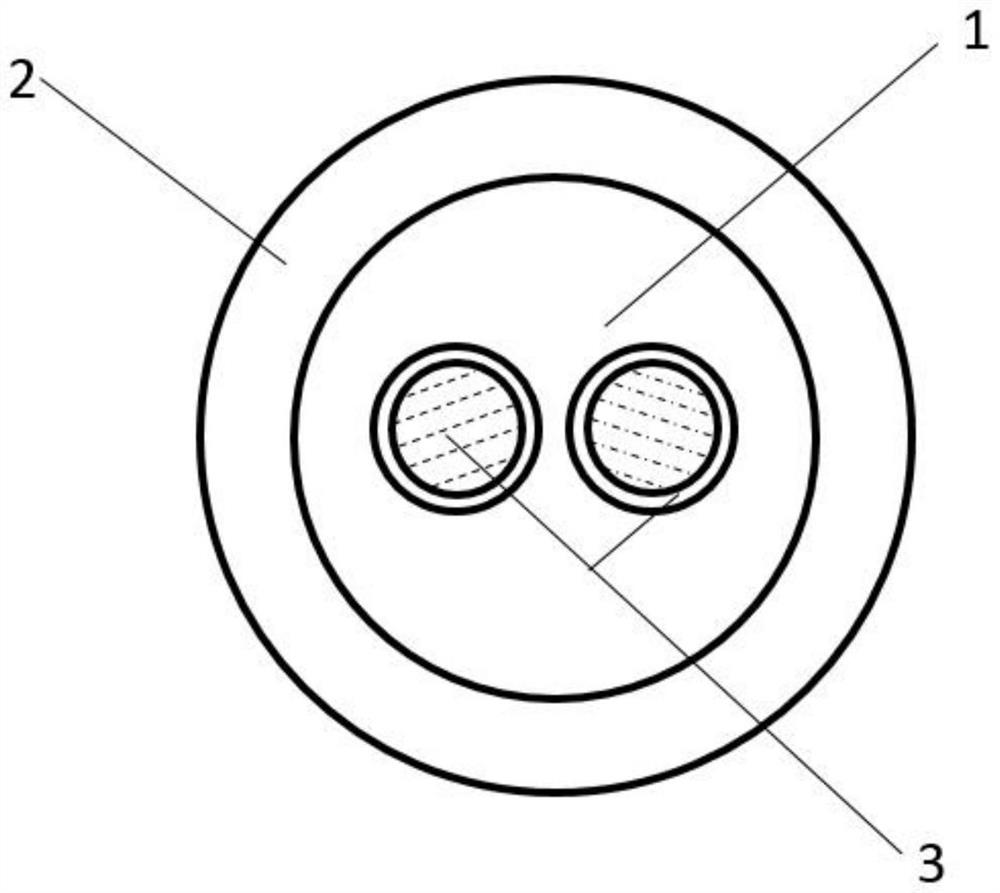

[0086] A laser shaping optical fiber is a multimode optical fiber, and its glass part with a circular cross section includes: a core and a cladding from the inside to the outside; the structure is as figure 2 Shown:

[0087] The core is circular, and the diameter of the circular cross-section of the circular core is 105 μm. The geometric central axis of the core or the central axis of the core precursor circle coincides with the geometric central axis of the fiber or is laterally offset by 5 μm.

[0088] The fiber core includes first and second doped regions that are symmetrical about the geometric center of the fiber core; the cross section of the doped region is annular, and the distance between the first and second doped regions is 20 μm; the first and The total area of the second two doped regions accounts for 10% of the total area of the fiber core.

[0089] The first doped region and the second doped region have different refractive index distributions. The interi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com