Heat recovery system for coal mine internal combustion engine heater

An internal combustion engine heater and heat recovery technology, applied in water heaters, fluid heaters, machines/engines, etc., can solve problems such as poor heat exchange effect, heat loss, sound and air pollution, and achieve easy cleaning and replacement and reduce wear and tear , the effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

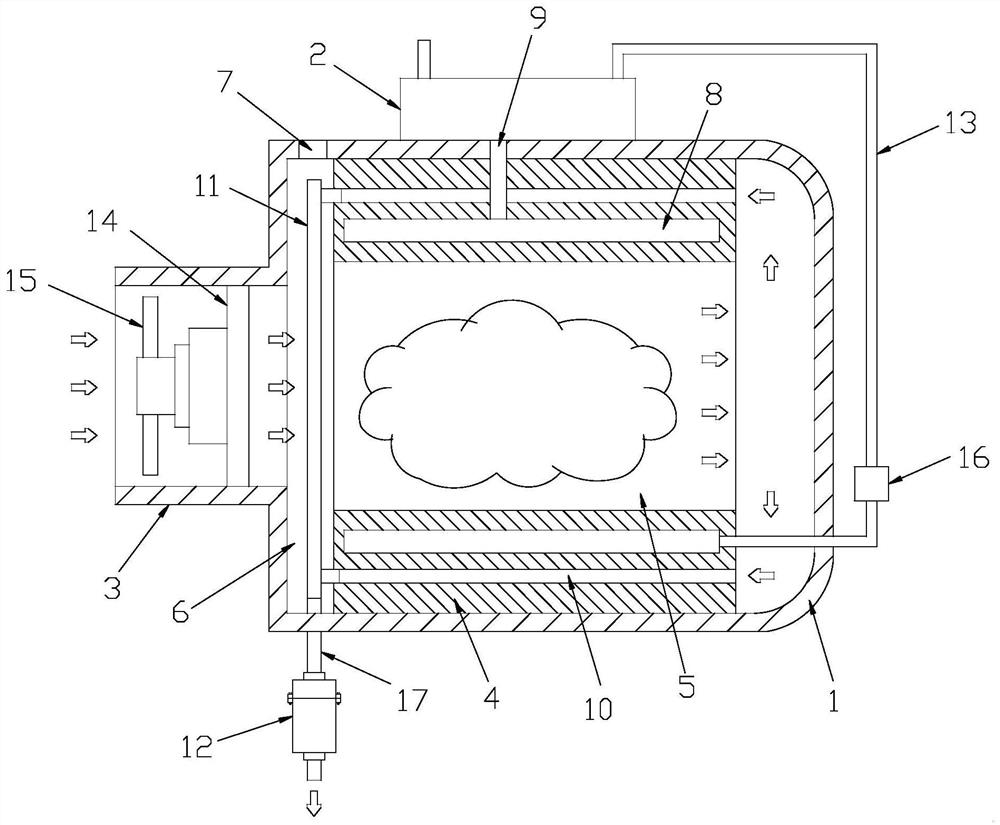

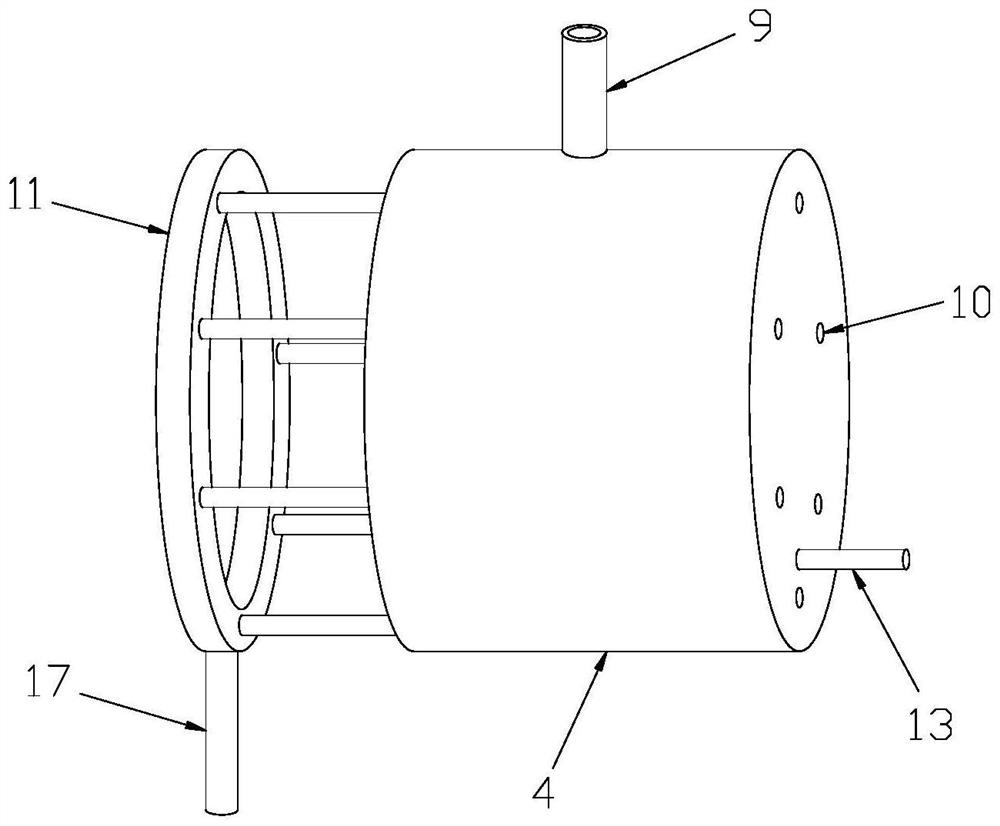

[0027] Example 1: See Figure 1-2 The present invention provides a technical solution: a heat recovery system including a coal mine, including a heater housing 1, a coolant storage case 2 located at the top of the heater housing 1 for storing a coolant; the heater The upper left end of the body 1 is provided with a vent, the air outlet 3 is attached to the mixing chamber 15, and the air can be transported to the mixing chamber 6 and the combustible product is combined after mixing by the combustion chamber 5. The inside of the heater housing 1 is provided with a steel cylinder 4, and there is a combustion chamber 5 inner, and the internal portion of the combustion chamber 5 has a silicon nitride ceramic, which can be heated to a high temperature, and the inside of the heater housing 1 is heated. The steel cylinder 4 is provided with a mixing chamber 6 on one side of the vent 3, and a combustible product is provided in the top of the heater housing 1, and the combustible material is...

Embodiment 2

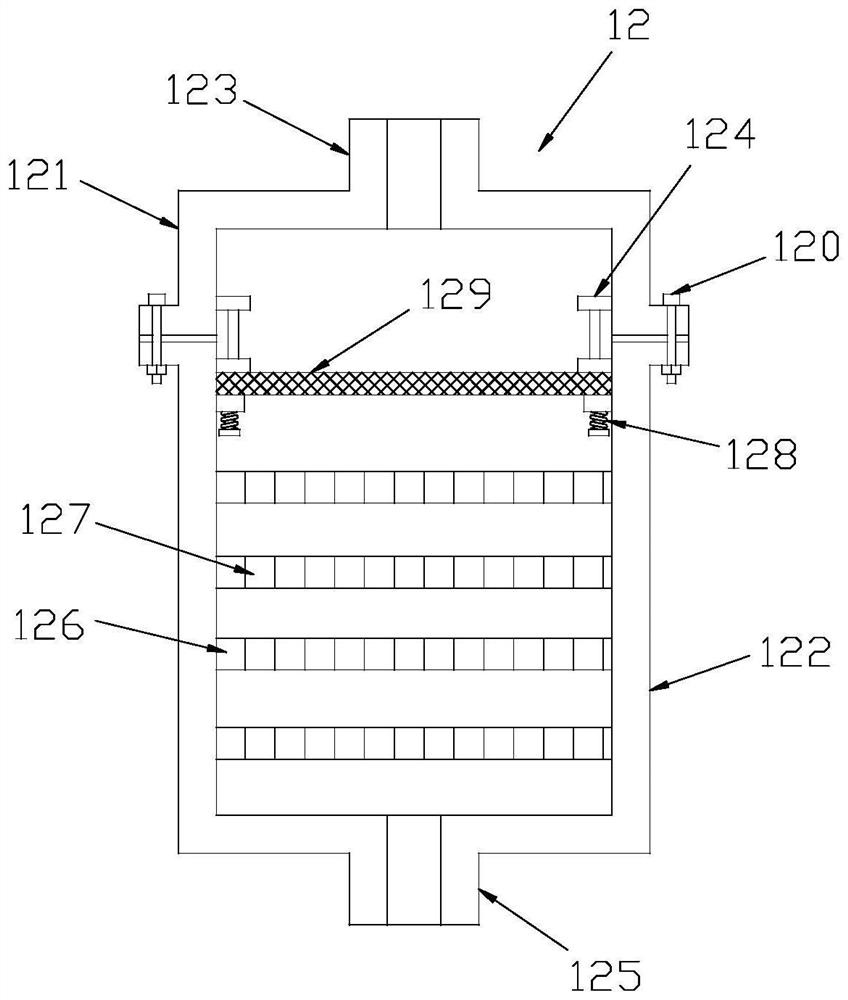

[0030] Example 2: See Figure 3-6The bottom end of the exhaust pipe 17 extends the outer portion of the heater housing 1 and is connected to an exhaust gas muff member 12, and the exhaust gas muff member 12 includes an upper casing 121 and at the bottom of the upper casing 121. The lower housing 122; the top of the upper housing 121 is provided with an intake port 123, and the intake port 123 is in communication with the exhaust pipe 17 for entering the exhaust gas into the exhaust muffle assembly 12; the upper housing 121 Both side inner walls are provided with a positioning member 124, and the positioning member 124 is configured to press the filter plate 129; the bottom portion of the lower case 122 is provided with air outlet 125 for discharge of gas after purification, muffin; The inner spacing of the lower case 122 is provided with a silencer plate 126, and a plurality of muffle holes 127 are provided on the silencer 126; the inner wall of the lower casing 122 is symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com