Pressure vessel and manufacturing method thereof

A technology for pressure vessels and pressure tanks, applied in the field of pressure vessels, can solve problems such as poor sealing effect, reduced usability, and potential safety hazards, and achieve the effects of good stability, improved performance, and less leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

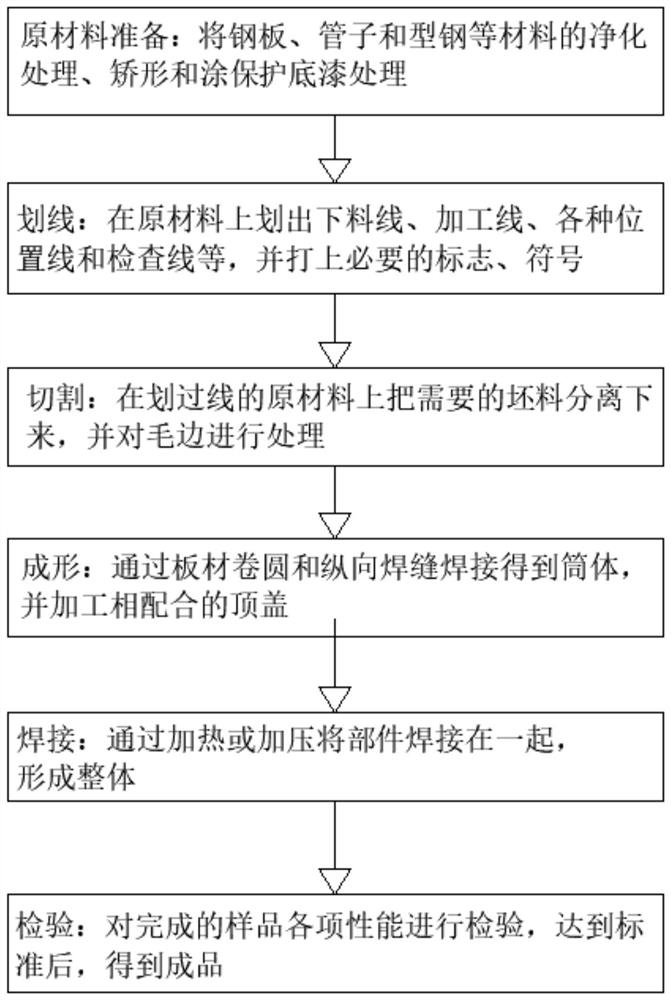

Method used

Image

Examples

Embodiment 1

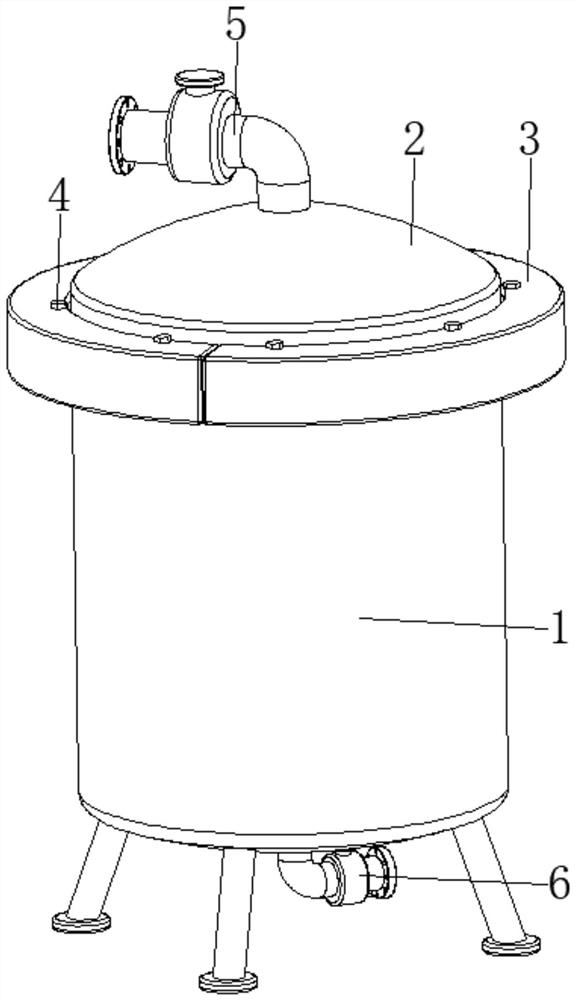

[0037] see Figure 1-7 , the present invention provides a technical solution: a pressure vessel, including a pressure tank body 1, a tank cover device 2, a pressing device 3, and a locking bolt 4. The tank cover device 2 is arranged on the top of the pressure tank body 1, and the pressing The device 3 is arranged at the position where the surface edge of the tank cover device 2 corresponds to the top edge of the pressure tank body 1, and the top surface of the pressure tank body 1, the surface edge of the tank cover device 2 and the clamping device 3 are all connected by locking bolts 4 fixed connection;

[0038] A material inlet 5 is provided at the center of the top of the cover device 21 , and a material outlet 6 is provided at the center of the bottom of the pressure tank body 1 .

[0039] The top of the surface of the pressure tank body 1 and the edge of the surface of the tank cover device 2 are provided with threaded holes matching the locking bolts 4, and the surface ...

Embodiment 2

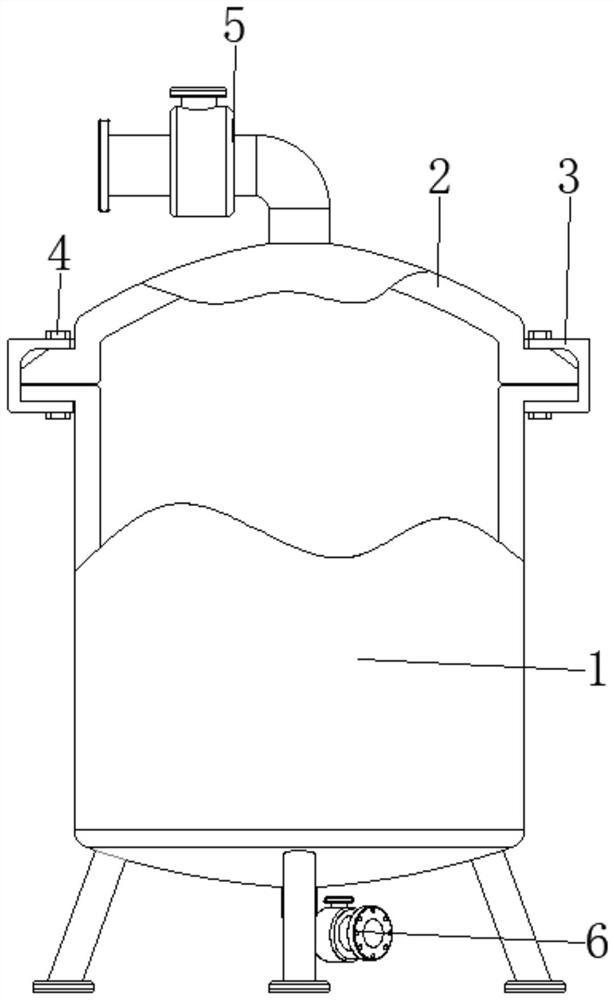

[0041] The tank cover device 2 is provided with a cover shell device 21, an arc-shaped elastic member 22, an arc-shaped bead 23, an elastic bag strip 24, and a stabilizing device 25. The cover shell device 21 is arranged on the top of the pressure tank body 1, and the arc-shaped elastic member 22 The bottom end is fixed on the bottom edge of the surface of the cover device 21 and is close to the edge, the bottom edge of the arc-shaped bead 23 is fixedly connected with the top of the arc-shaped elastic member 22, and the elastic bag strip 24 is arranged on the surface of the cover device 21 and the arc-shaped bead 23 Between the corresponding two sides of the bottom and close to the arc-shaped elastic member 22, the stabilizing device 25 is arranged on the surface edge of the cover device 21 and close to the position of the elastic bag strip 24, and is clamped by the clamping device 3 and combined with The locking of the locking bolt 4 causes the clamping pressure to be applied ...

Embodiment 3

[0046] The clamping device 3 is provided with an arc-shaped clamping base 31, a notch clamping groove 32, and a limit groove 33. The arc-shaped clamping base 31 is arranged at a position corresponding to the edge of the surface of the cover device 21 and the top of the surface of the pressure tank body 1. The notch The card slot 32 is set inside the arc-shaped pressing base 31 and is located on one side of the surface. The inner surface of the inner surface is opened with a notch slot 32, and then the position corresponding to the top edge of the surface of the pressure tank body 1 and the surface edge of the cover body 211 can be clamped, and the stabilizing device 25 is used to cooperate with the limiting groove 33, and then the cover shell The main body 211 is positioned so that the space between the pressure tank body 1 and the cover shell main body 211 is not easy to move arbitrarily, and the influence of vibration is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com