Scribing saw blade spindle structure

A dicing machine and blade technology, which is applied in the direction of mechanical equipment, transmission parts, fine working devices, etc., can solve the problems of high cost, poor sealing, and low precision of the air-floating electric spindle, so as to reduce jitter and improve sealing Sexuality, the effect of improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

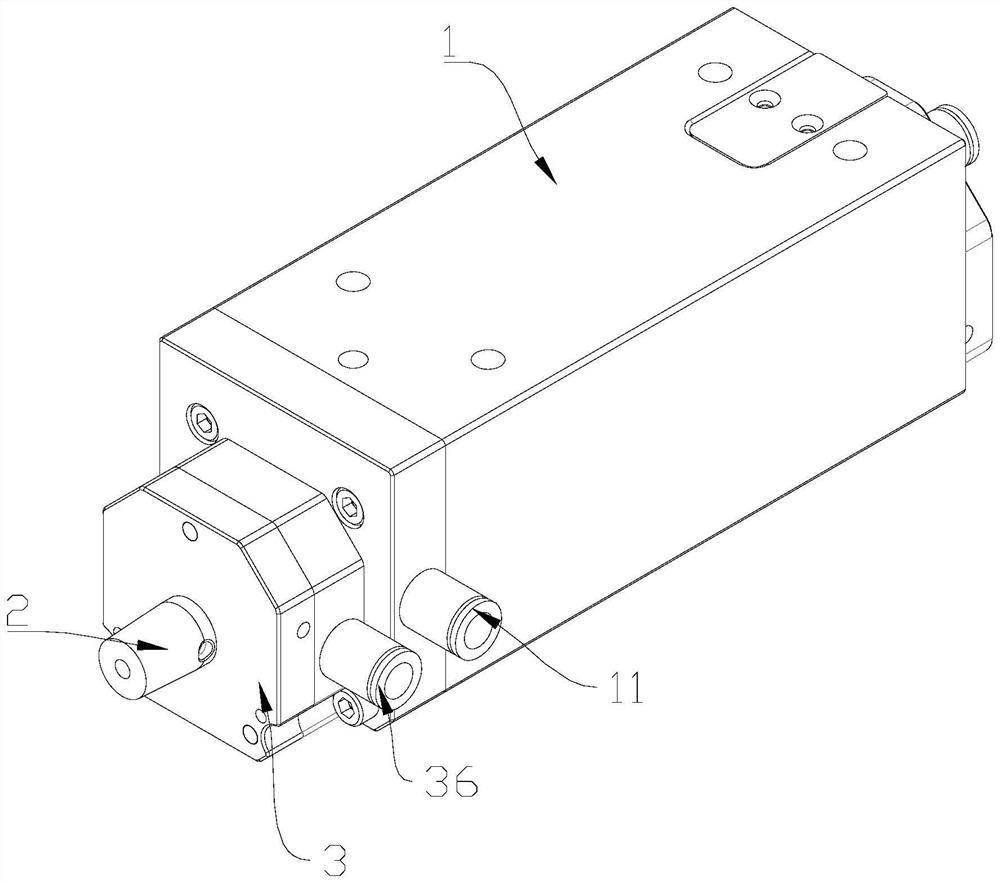

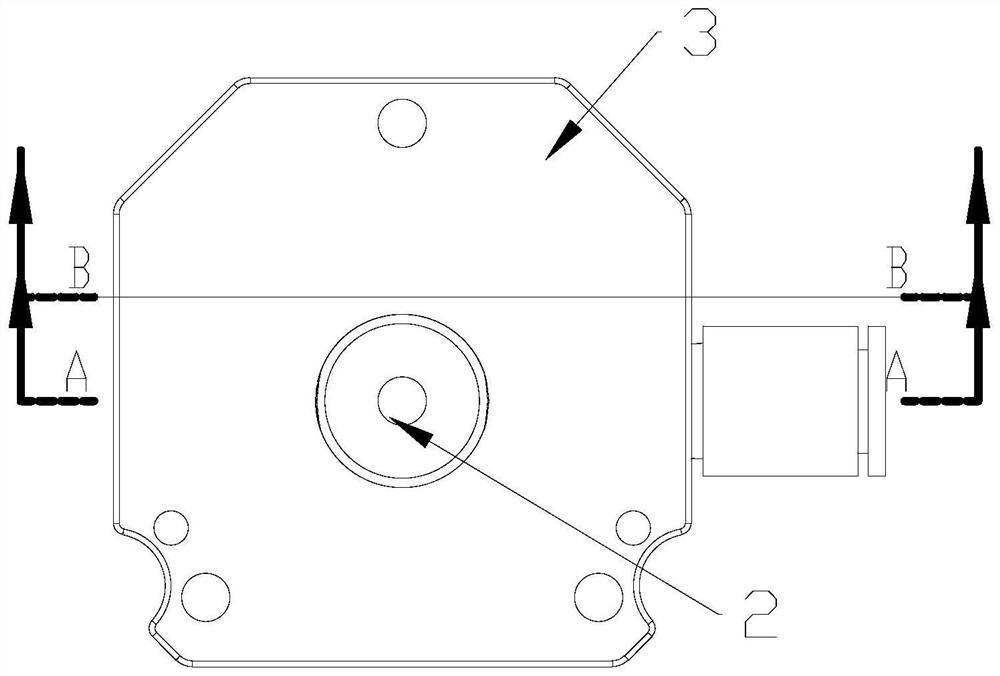

[0028] See attached figure 1 As shown, the blade spindle structure of the dicing machine of the present invention includes a housing 1 , a rotating shaft 2 and an exhaust extruding device 3 .

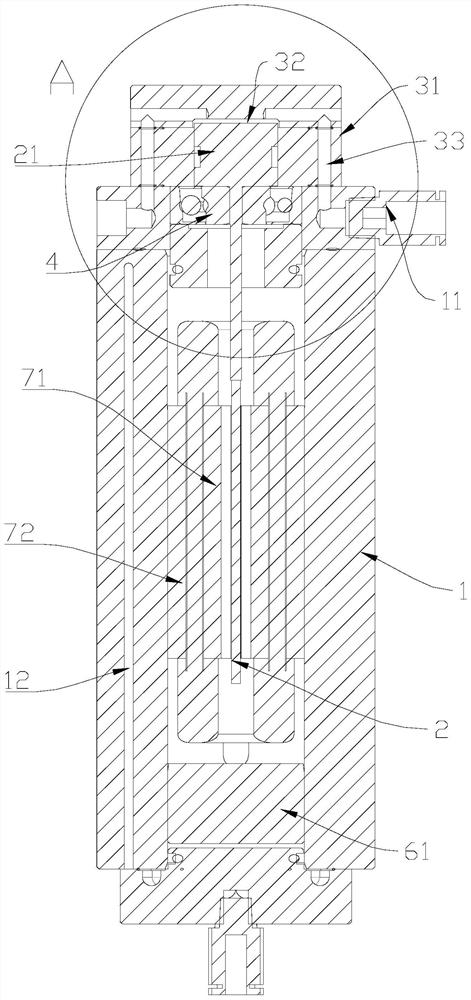

[0029] Refer to attached figure 2 , 3 As shown in and 5, the housing 1 includes a shell with an opening at one end and a front cover that covers the opening. The shell is made of aluminum alloy, which has good heat dissipation performance and is easy to process. The rotating shaft 2 is rotatably connected in the casing 1, and one end passes through the front cover. The front end of the casing 1 is provided with an angular contact ball bearing 4 sleeved on the outside of the rotating shaft 2, and the rotating shaft 2 can move forward and backward along its axial direction. The rotating shaft 2 can move slightly along the axis, and when moving toward the angular contact ball bearing 4, it can press the angular contact ball bearing 4, improve the rotation stability, and reduce the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com