Prefabricated assembly type building splicing plate and splicing method thereof

A prefabricated assembly and plate technology, applied in construction, building construction, etc., can solve the problems of bolt breakage, slowness, and cumbersome plate installation process, and achieve the effect of avoiding bolt breakage and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

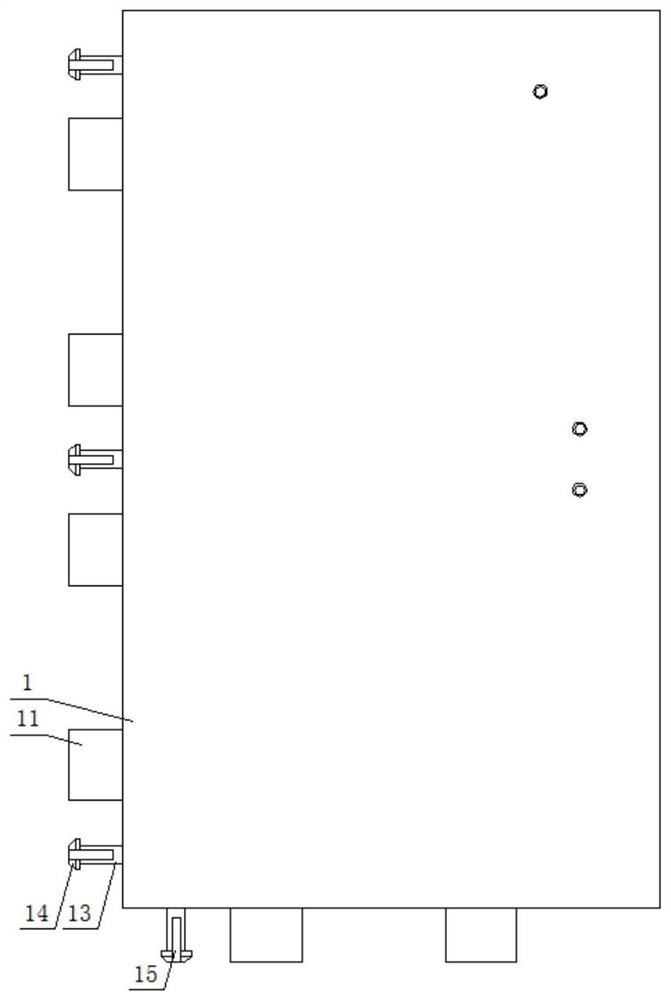

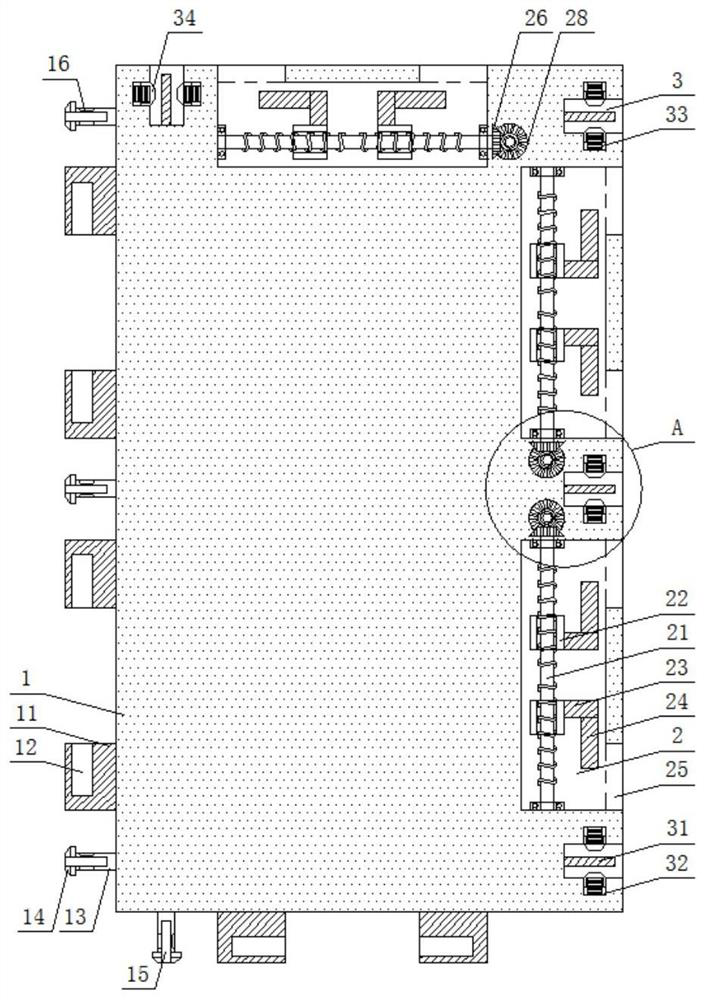

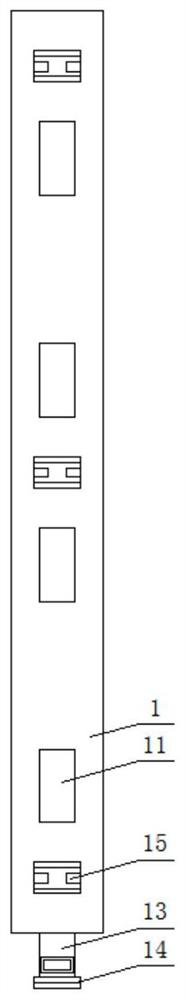

[0035] Embodiment 1: This embodiment provides prefabricated assembled building splicing panels, see Figure 1-7 Specifically, it includes a plate 1 and a limit assembly. The plate 1 is a rectangular plate placed vertically. There are rectangular cavities 2 in the middle of the top surface and the upper and lower sides of the right side of the plate 1. Each rectangular cavity 2 Two-way lead screws 21 placed in parallel are arranged inside, fixed bearings are arranged on the inner wall of the rectangular cavity 2 at positions corresponding to the two ends of the two-way lead screws 21, and the two ends of each two-way lead screw 21 are inserted into the In the corresponding fixed bearing, the thread teeth on the two sections of the two-way lead screw 21 are symmetrically arranged, and the two ends of each rectangular cavity 2 are provided with limiting through holes 25, and the bottom surface and the left side surface of the plate 1 have two upper and lower sides. A pair of limi...

Embodiment 2

[0038] Embodiment 2: In Embodiment 1, there is still the problem that the plates are simply snapped and locked through the limiting plate, which cannot guarantee the stability of the splicing of the plates. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0039] Specifically, see figure 2 with Figure 5 , one side of the top surface of the plate 1 and the middle and lower ends on the right side are provided with positioning grooves 3, and one side of the bottom surface of the plate 1 and the middle and lower ends on the left side are all provided with positioning plates 13, and each positioning plate 13 are all matched and inserted in the positioning groove 3 of another plate 1; the outer end of the positioning plate 13 is provided with a trapezoidal block 14, and the front and rear sides of the positioning plate 13 and the trapezoidal block 14 are all provided with a card slot 15, and the positioning groove 3 Blocks 31 are provided on the front and ...

Embodiment 3

[0041] Embodiment three: see Figure 8 , in this embodiment, the present invention also proposes a splicing method for prefabricated building splicing panels, including the following steps:

[0042] Step 1, when two boards 1 are spliced together, the trapezoidal block 14 and the positioning plate 13 are inserted into the positioning groove 3 of the other one, the block 31 slides along the corresponding slot 15, and the trapezoidal block 14 drives the trapezoidal cap 34 along the Sliding inward along the spring groove 32, drives the spring 33 to be compressed and deformed;

[0043] Step 2, when the trapezoidal block 14 is completely pressed against the positioning groove 3, the tension of the spring 33 will drive the trapezoidal cap 34 to slide outward along the spring groove 32, and drive the top end of the trapezoidal cap 34 against the trapezoidal groove 16 , so that the trapezoidal cap 34 is pressed against the trapezoidal block 14;

[0044] Step 3, when the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com