Collagen zymolyte with blood sugar reducing effect as well as preparation method and application of collagen zymolyte

A collagen and enzymatic hydrolyzate technology, applied in the field of collagen protease hydrolyzate and its preparation, can solve problems such as no breakthrough, and achieve the effects of realizing enzymatic hydrolysis controlled release, simple process, and improving oral glucose tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

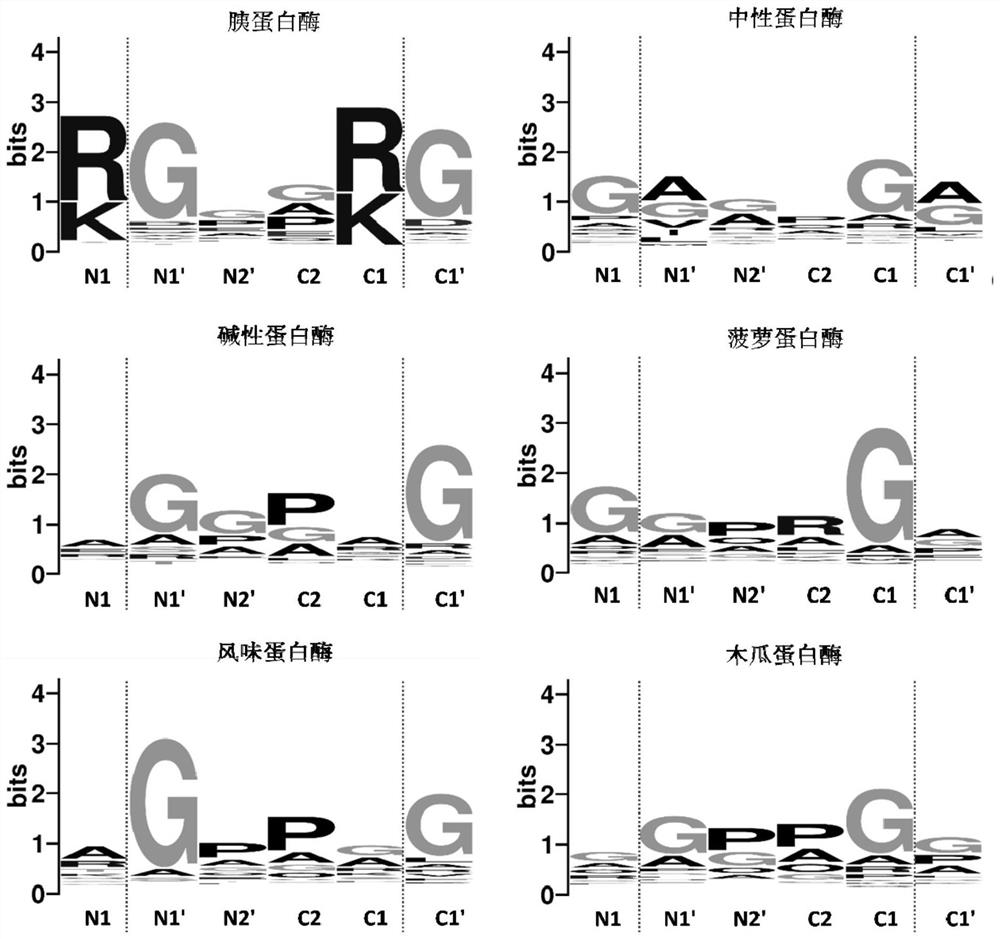

Method used

Image

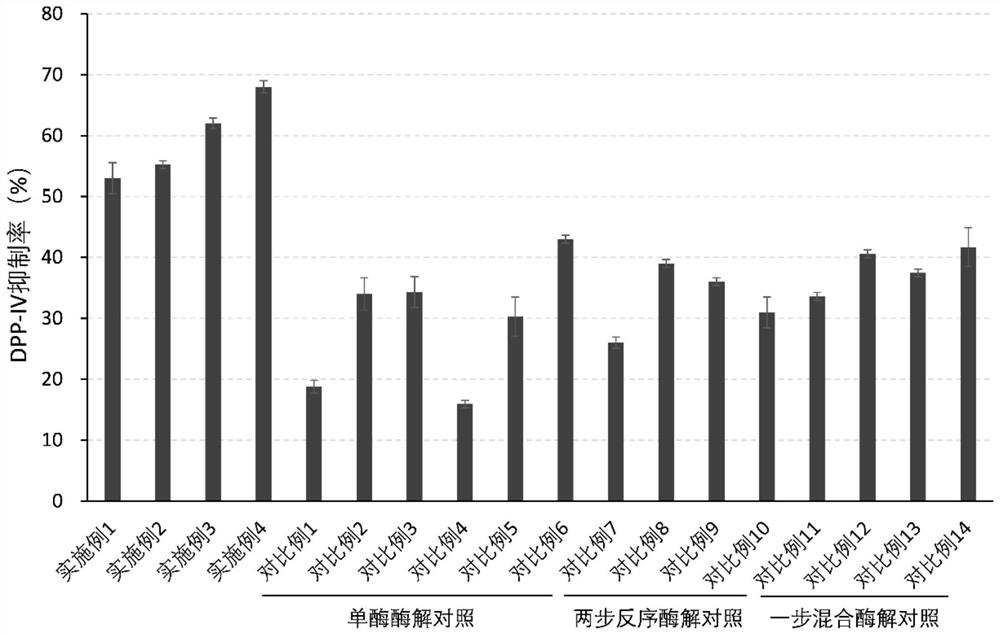

Examples

Embodiment 1

[0050] The preparation method of fish skin hydrolyzate comprises the following steps:

[0051] (1) Thaw 1 kg of fish skin (tilapia fish skin, the same below), drain the water, then add 6L of 0.05% sodium hydroxide solution, soak for 4 hours, wash with running water until neutral, and obtain alkali-treated fish. Skin;

[0052] (2) adding alkali-treated fish skin to 10 L of hot water at a temperature of 90° C., and heat-treating for 5 hours to obtain a heat-treated fish skin solution;

[0053] (3) Cool the heat-treated fish skin solution to 37° C., adjust the pH value of the solution to 8.0, add 1 g of trypsin to it, enzymatically hydrolyze it for 8 hours, and then inactivate the enzyme at 95° C. for 30 minutes to obtain a solution after enzymatic hydrolysis;

[0054](4) Cool the solution after the first enzymolysis to 50°C, adjust the pH value to 7.0, add 1g bromelain and 1g neutral protease to it, and after enzymolysis for 6h, inactivate the enzyme at 95°C for 30min to obtain...

Embodiment 2

[0058] The preparation method of fish skin hydrolyzate comprises the following steps:

[0059] (1) Thaw 1.4 kg of fish skin, drain the water, then add 7 L of 2% sodium hydroxide solution, soak for 2 hours, wash with running water until neutral, and obtain alkali-treated fish skin;

[0060] (2) adding the alkali-treated fish skin to 21 L of hot water at a temperature of 95° C., and heat-treating for 4 hours to obtain a heat-treated fish skin solution;

[0061] (3) Cool the heat-treated fish skin solution to 50°C, adjust the pH value of the solution to 7.0, add 1.2g of flavor protease to it, and after enzymolysis for 6 hours, inactivate the enzyme at 95°C for 30 minutes to obtain a solution after enzymolysis ;

[0062] (4) Cool the solution after the first enzymolysis to 50°C, adjust the pH value to 7.0, add 1.5g of neutral protease and 1.5g of papain to it, and after enzymolysis for 6h, inactivate the enzyme at 95°C for 30min to obtain For the solution after the second enzyma...

Embodiment 3

[0066] The preparation method of fish skin hydrolyzate comprises the following steps:

[0067] (1) Thaw 0.6 kg of fish skin, drain the water, then add 4 L of 1.5% sodium hydroxide solution, soak for 2.5 hours, wash with running water until neutral, and obtain alkali-treated fish skin;

[0068] (2) adding the alkali-treated fish skin to 5 L of hot water at a temperature of 85° C., and heat-treating it for 6 hours to obtain a fish skin solution after heat treatment;

[0069] (3) Cool the heat-treated fish skin solution to 37° C., adjust the pH value of the solution to 8.0, add 2 g of trypsin to it, enzymatically hydrolyze it for 4 hours, and inactivate the enzyme at 95° C. for 30 minutes to obtain a solution after enzymatic hydrolysis;

[0070] (4) Cool the solution after the first enzymolysis to 50°C, adjust the pH value to 7.0, add 1.5g bromelain and 1g papain to it, and after enzymolysis for 10 hours, inactivate the enzyme at 95°C for 30 minutes to obtain the second The solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com