A kind of modified coffee grounds, its preparation method and a kind of pervious concrete using the same

A technology of permeable concrete and coffee grounds, applied in the field of building materials, can solve the problems of high cost, achieve low cost, reduce the risk of heavy metal pollution, and have good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] (1) Preparation of modified coffee grounds:

[0029] 50 g of coffee grounds were pretreated with 0.01 mol / L KOH alkaline solution for 60 min, and then washed with deionized water until neutral. Then, it was added to 1L of a mixed solution of 200g / L NaOH and 30g / L cetyltrimethylammonium bromide for reaction, and the reaction was carried out at 250rpm in a magnetic stirrer for 2h to increase the adsorption sites on the surface of coffee grounds. The drained solids were washed with deionized water until neutral, dried and passed through a 40 mesh screen.

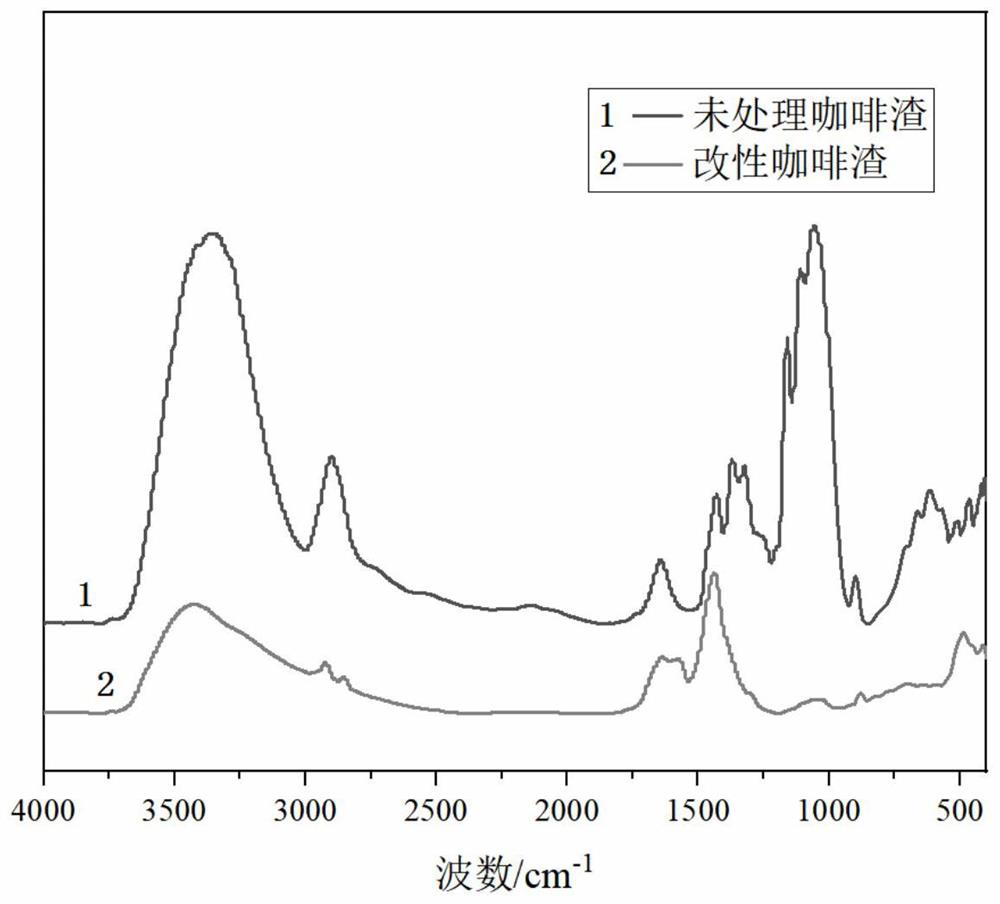

[0030] Infrared spectroscopy analysis of untreated coffee grounds and modified coffee grounds yielded the following results: figure 1 shown. Compared with the untreated coffee grounds, the modified coffee grounds have the following groups: -OH (3424.03 cm -1 ), carboxyl group, ester group or aldehyde group C=O (1773.88cm -1 and 1638.45cm -1 ), C-O of ester group (1020.69cm-1), C-H of aromatic ring (901.34cm-1, 834.2...

Embodiment 1

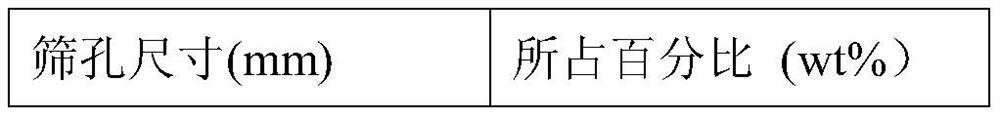

[0033] Using the jarring standard vibrating screen machine developed by the Building Materials Institute of China Academy of Building Research, model: ZBSX 92A, vibration frequency: 221min, swing stroke: 25mm, jarring frequency: 147min, motor power: 0.37Kw. According to the sieve size (mm)>20 (22.2%), 16-20 (28.8%), 10 (40%), <5 (9%) coarse aggregate gradation standard, screen 980g of crushed stone.

[0034] Wet the contact equipment such as mixers and tools with water, and then mix the modified coffee grounds (17.5g), ordinary Portland cement (332.5g) with a label of P.O42.5, polyvinyl acetate (52.5g) and polycarboxylate Pour the acid-based superplasticizer (17.5g) into the mixer and stir evenly, then add water (105g), stir for 3-5 minutes, then add crushed stone (980g) and industrial sand (420g) to the mixer, and continue to stir until uniform.

[0035] The obtained mixed slurry was poured into a 100mm×100mm×100mm mold, and pressurized by a press to a molding pressure of 3M...

Embodiment 2

[0037] Using the jarring standard vibrating screen machine developed by the Building Materials Institute of China Academy of Building Research, model: ZBSX 92A, vibration frequency: 221min, swing stroke: 25mm, jarring frequency: 147min, motor power: 0.37Kw. According to the sieve size (mm)>20 (22.2%), 16-20 (28.8%), 10 (40%), <5 (9%) coarse aggregate gradation standard, screen 980g of crushed stone.

[0038] Wet the contact equipment such as mixers and tools with water, and then mix modified coffee grounds (35g), slag Portland cement (315g) with the label P.S 42.5, polyoxyethylene (52.5g) and sulfonic acid-based water reducing agent (17.5g) g) Pour it into the mixer and stir evenly, then add water (105g), stir for 3-5 minutes, then add crushed stone (980g) and industrial sand (420g) into the mixer, and continue to stir until uniform.

[0039] The obtained mixed slurry was poured into a 100mm×100mm×100mm mold, and pressurized by a press to a molding pressure of 3MPa. Steam cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com