Carton sealing machine belt guiding device capable of preventing rubber belt from being derailed and trailing

A sealing machine and adhesive tape technology, which is applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems that the tape cannot be completely bonded, the tape cannot be cut, and the tape is not on the center line, etc., so as to avoid incomplete bonding Cartons, ensuring long-term safe use, and improving the effect of sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention are further specifically described below by way of examples and in connection with the accompanying drawings.

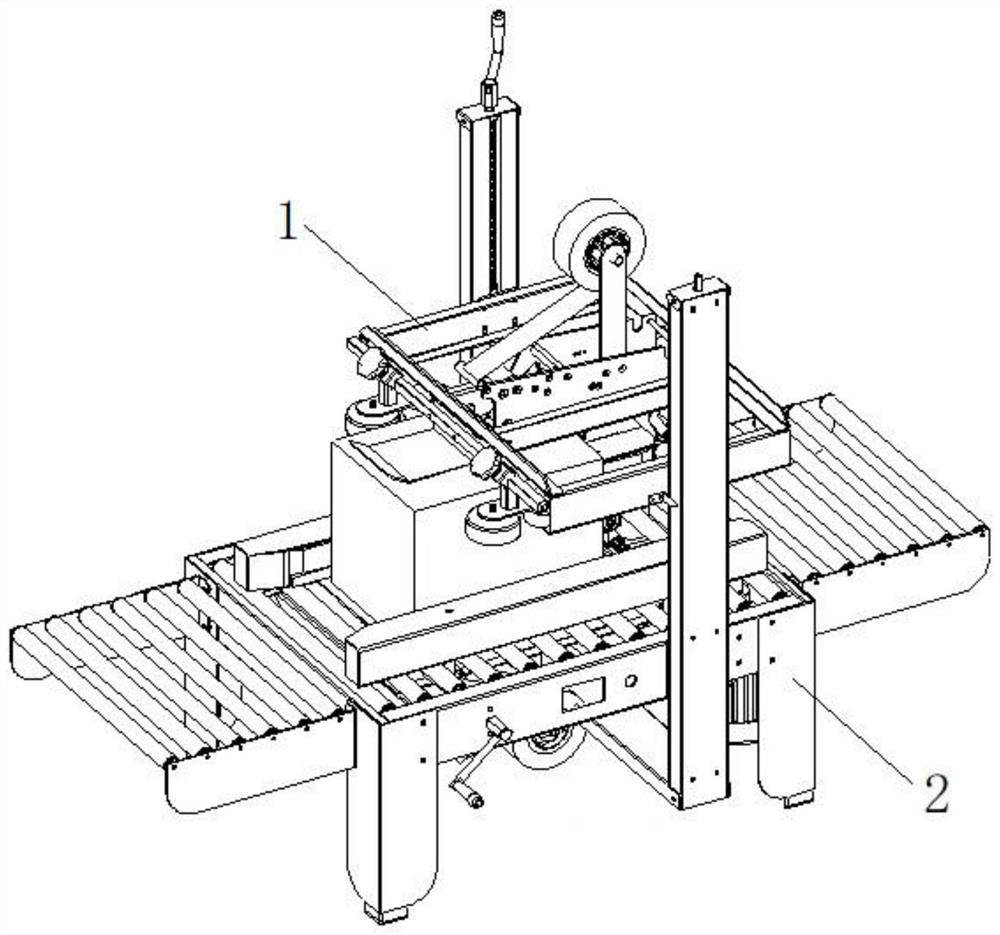

[0032] In this embodiment, a sealing machine belt device for a sealing machine facing tape is derailed, such as figure 1 As shown, the tape 3 is installed, guided, cut off, and the other functions such as each other, forming a movement 1, directly mounted on the packed pipeline rack 2.

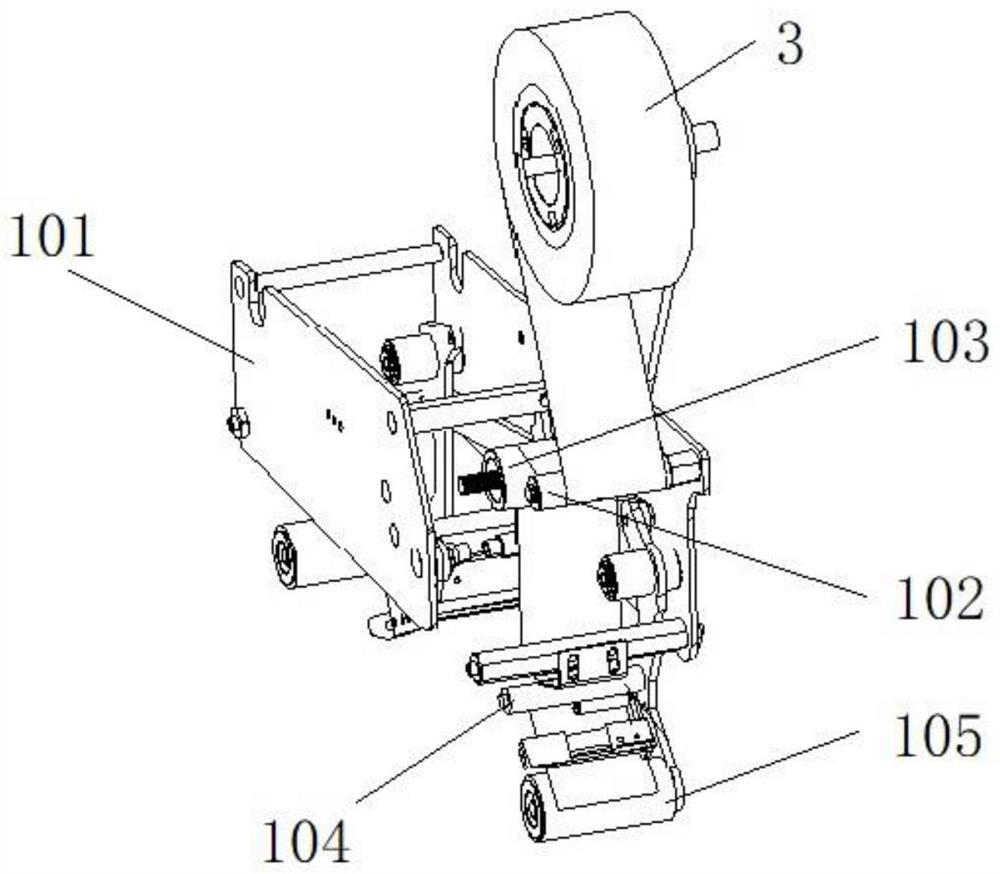

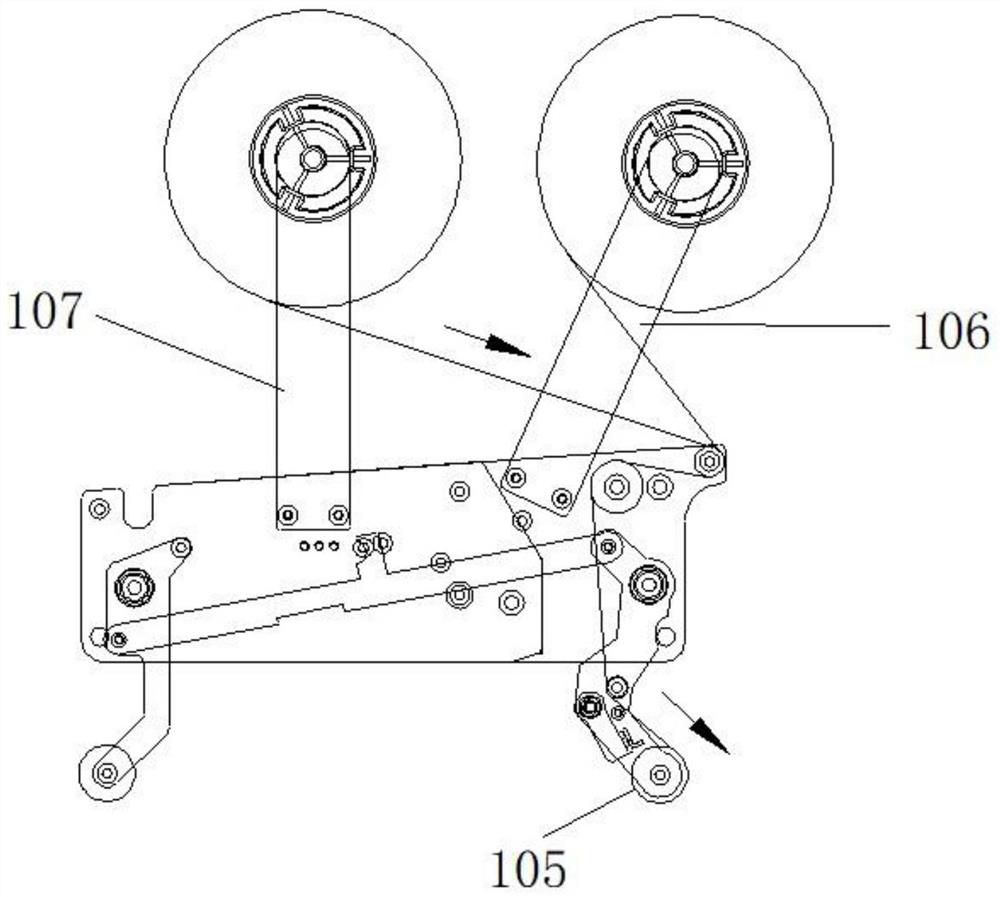

[0033] Specific structure Figures 2 to 4 As shown, the movement 1 includes a movement mount 101, and a first rubber bracket 106 and a second rubber bracket 107 are provided in the front-rear position in the stepped movement direction, and the two brackets are respectively provided with a positioning tape 3. The film wheel. Paralleled with the axis of the coil film wheel, the first guide roller 102 is provided, and the one-way roller 103 is provided on the rear side of the first guide roller 102, and the one-way roller 103 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com