Self-adjusting anti-collision sleeve for positioning firmware

An anti-collision, self-adjusting technology, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as risks, long working hours, and inconvenient vehicle assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

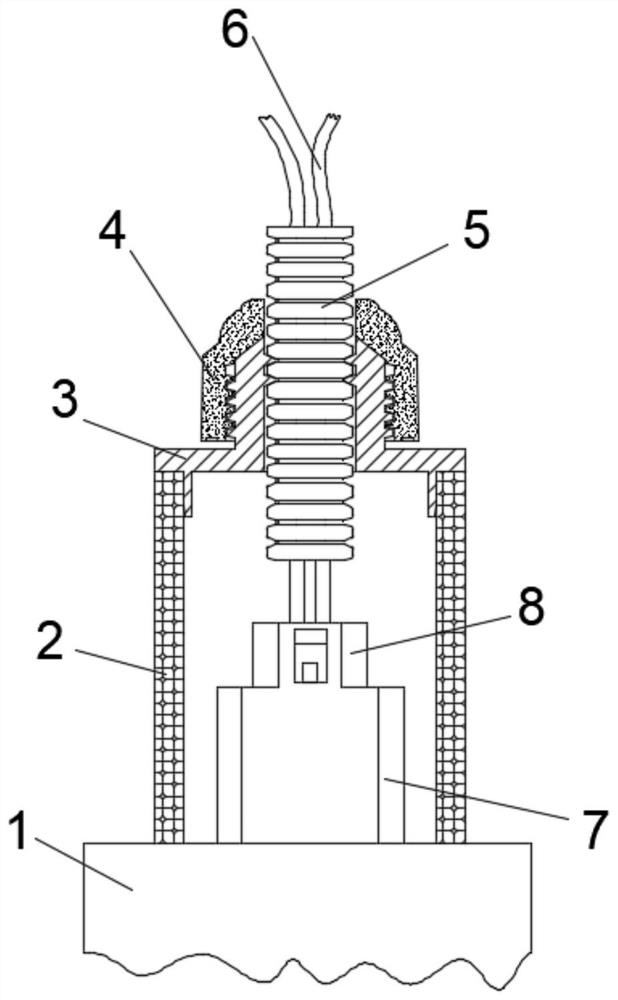

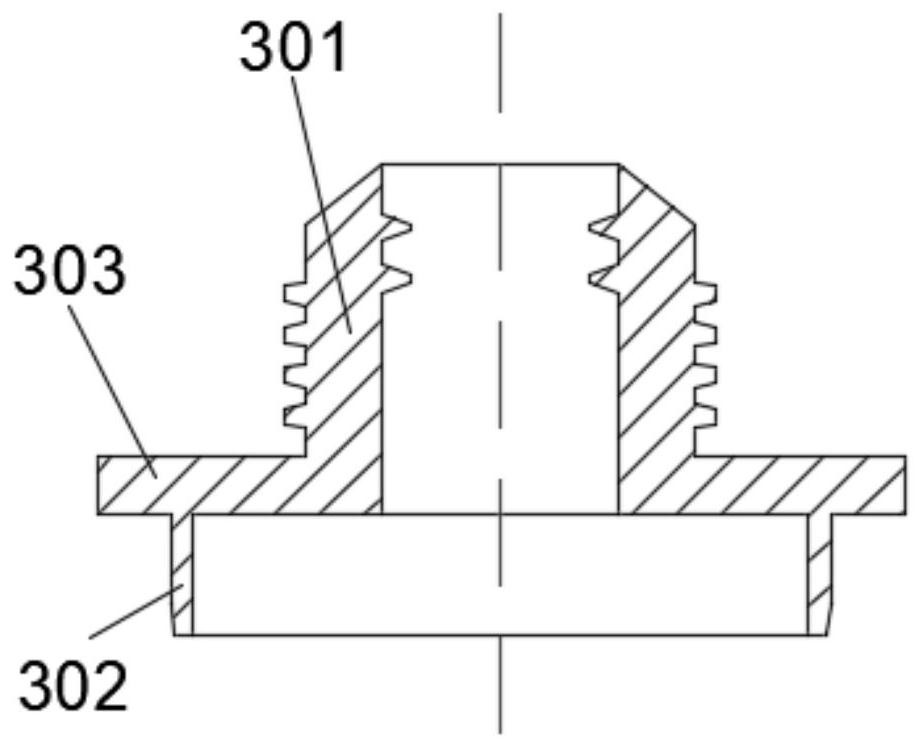

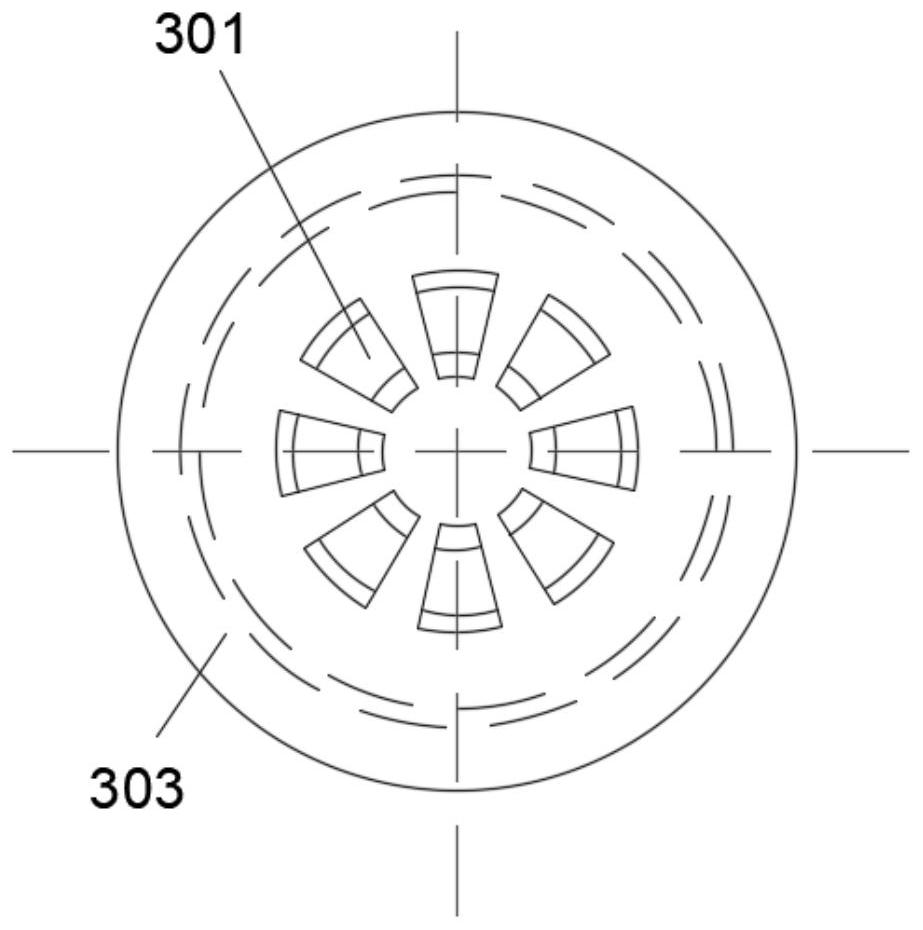

[0047] see Figure 1-6 , an embodiment provided by the present invention: a self-adjusting positioning fixture anti-collision sleeve, comprising: a tubular component 2, a positioning fixture 3, one end of the tubular component 2 is fixed to the positioning fixture 3, and the tubular component 2 , The positioning fixture 3 is sleeved on the outside of the wire 6 , and the wire 6 is connected to the fixing base 1 .

[0048] Preferably, the tubular assembly 2 is provided with an insulating layer (such as the tubular assembly 2 is an anti-collision insulating layer, preferably, the anti-impact insulating layer is more than one layer; the tubular anti-impact insulating layer defines an open relative a lumen extending along the central longitudinal axis between the two ends);

[0049]Preferably, the material of the tubular component 2 includes plastic, silicone rubber, etc.;

[0050] Preferably, the manufacturing method of the tubular component 2 includes warp and weft weaving, cr...

Embodiment 2

[0066] refer to Figure 7 , on the basis of the above-mentioned embodiment 1, a bellows fastening device is arranged between two elastic fingers 301, and the bellows fastening device is used for fastening the bellows 5 by the elastic fingers 301 .

[0067] The bellows fastening device includes:

[0068] The first chute 901, the first rack 902, the elastic connecting rod 903, the clamping member 904, the limiting member 905, the synchronous gear 906, the second chute 907, the second rack 908, the first connecting block 909, the first A rotating shaft 910, a second connecting block 911, a second rotating shaft 912, a first spring 913, a telescopic rod 914, a first connecting rod 915, a second connecting rod 916, a third chute 917, a third rotating shaft 918, and a third connection block 919;

[0069] The first chute 901 is disposed in the elastic finger 301, the first rack 902 is slidably connected to the first chute 901, and one end of the first rack 902 is connected to the ...

Embodiment 3

[0083] refer to Figure 8-10 , on the basis of the above-mentioned embodiment 1 or 2, the outer periphery of the fastening component 4 is provided with an anti-loosening device, and the anti-loosening device is used to prevent the fastening component 4 from disengaging from the positioning member 3 during use .

[0084] The anti-loosening device includes:

[0085] Push housing 1001, fixed housing 1002, first limit block 1003, second limit block 1004, ratchet 1005, ratchet 1006, second spring 1007, third spring 1008, pawl 1009, hinge support 1010, Telescopic sleeve 1011, fourth rotating shaft 1012, fifth rotating shaft 1013;

[0086] The outer periphery of the fastening assembly 4 is fixed with the ratchet 1005, the middle of the ratchet 1005 is provided with the ratchet 1006, the push shell 1001 is arranged outside the ratchet 1005, and the fastening assembly 4 runs through the Press the shell 1001;

[0087] The second spring 1007 is sleeved on the ratchet 1005, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com