Discharging air cooling device and air cooling method for cold pilger mill

A technology of cold-rolled pipe mill and air-cooling device, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as easy deformation, achieve deformation prevention, improve quality and pass rate, and excellent cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

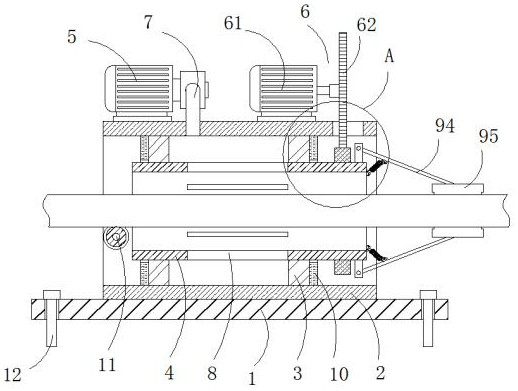

[0028] In order to overcome the problem in the prior art that the pipe is easily deformed by the high temperature of cold rolling during the transmission process after cold rolling in the cold rolling mill, the present invention provides such figure 1 A discharge air cooling device for a cold-rolled pipe mill is shown. The present invention can comprehensively and rapidly cool down the pipes output from the cold-rolled pipe mill, prevent the pipes from being deformed during transportation after cold rolling, and improve the temperature of the cold-rolled pipes. At the same time, the device also has the function of self-cleaning lubricating oil on the surface of the pipe without manual operation, which reduces the labor intensity of the staff.

[0029] Such as figure 1 and figure 2 As shown, a discharge air cooling device for a cold rolling mill includes a mounting plate 1, the upper surface of the mounting plate 1 is fixedly connected with a cooling cylinder 2, and the inner...

Embodiment 2

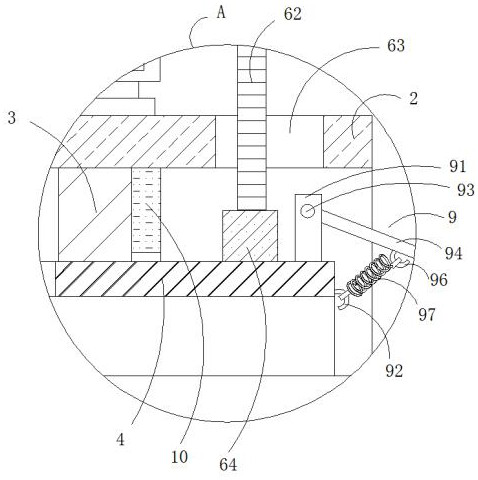

[0032] Such as figure 1 and figure 2 As shown, on the basis of Embodiment 1, preferably, the drive mechanism 6 includes a drive motor 61 fixedly connected to the outer wall of the cooling cylinder 2, the output end of the drive motor 61 is fixedly connected to a gear 62, and the outer wall of the cooling cylinder 2 is opened. There is a connecting through hole 63 matched with the gear 62 , and the outer wall of the side end of the cooling pipe 4 is fixedly sleeved with an external gear ring 64 , and the external gear ring 64 and the gear 62 mesh with each other.

[0033] In actual use, the driving mechanism 6 rotates the cooling pipe 4, and the rotating cooling pipe 4 enables the air discharged from the rectangular air outlet 8 to completely cool the surface of the pipe, improving the cooling effect and reliability of the pipe. Both the starting air pump 5 and the driving motor 61 are electrically connected to the external power supply through the control switch. This electr...

Embodiment 3

[0035] On the basis of embodiment 1 or embodiment 2, such as figure 1 and figure 2As shown, preferably, the lubricating oil cleaning mechanism 9 includes a U-shaped block 91 fixedly connected to the outer wall of the side end of the cooling pipe 4, a first hook 92 fixedly arranged on the end surface of the same side of the cooling pipe 4, and the U-shaped block 91 Both sides of the outer wall are provided with round holes, and each round hole is movably connected with a rotating rod 93, the outer wall of the rotating rod 93 is fixedly connected with an extension rod 94, and the end of the extension rod 94 is connected with a cleaning blade 95.

[0036] In actual use, round holes are provided on the outer walls of both sides of the U-shaped block 91, and each round hole is movably connected with a rotating rod 93, and the outer wall of the rotating rod 93 is fixedly connected with an extension rod 94, and the end of the extension rod 94 is connected to There is a cleaning scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com