Damp-heat-resistant leather retanning agent polymerization reaction device

A technology of polymerization reaction and retanning agent, which is applied in the direction of feeding device, chemical/physical/physical-chemical stationary reactor, chemical instrument and method, etc., can solve the problem that the polymerization raw materials cannot be uniformly and fully mixed, and the ingredients are returned to the blanking material. The internal problems of the pipe can be solved, so as to achieve the effect of uniform and thorough mixing of ingredients, convenient feeding and prolonging of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

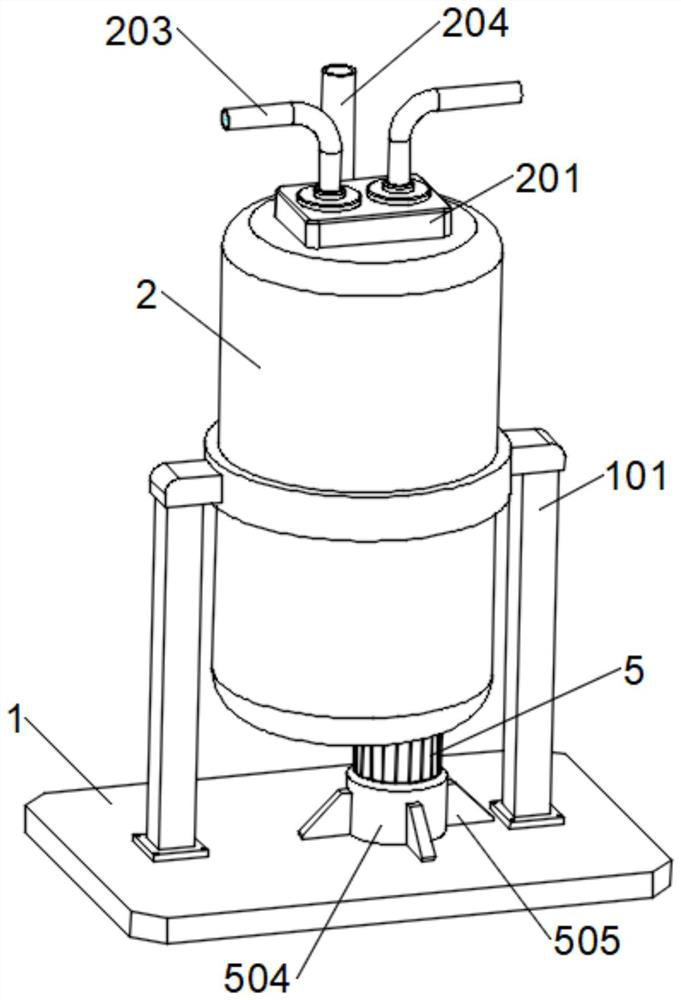

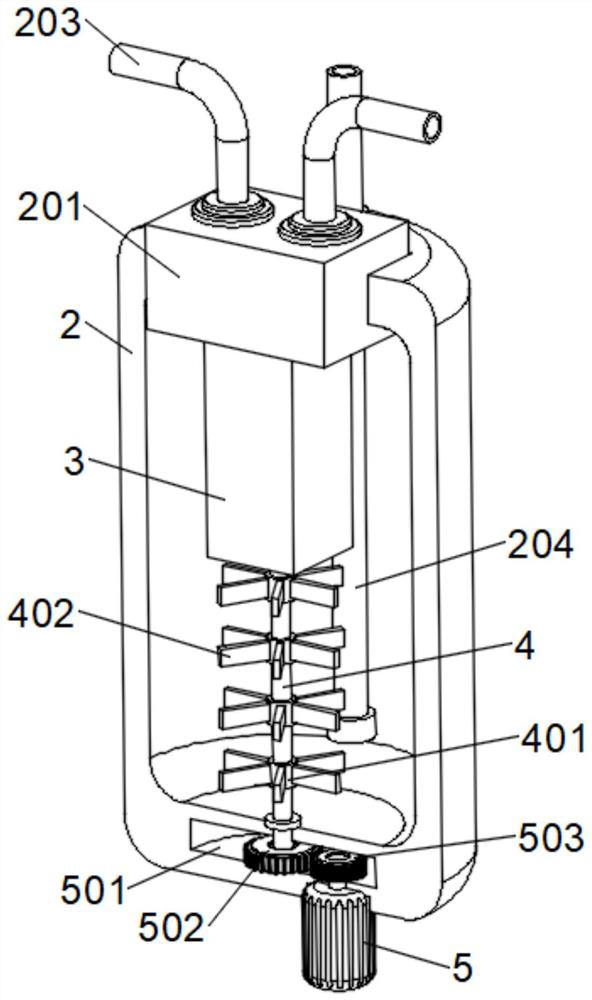

[0033] refer to Figure 1-5 The shown one kind of heat and humidity resistant leather retanning agent polymerization reaction device comprises a base 1, a reactor body 2 arranged above the base 1 and an installation block 3 arranged inside the reactor body 2, and the upper surface of the base 1 is fixed by a fixing frame 101, the reactor body 2 is fixed above the base 1 through the fixing frame 101, and there is a gap between the reactor body 2 and the upper surface of the base 1, the inside of the reactor body 2 is hollow, and the upper end of the reactor body 2 is embedded and fixed There is a blanking base 201 that penetrates to the interior of the reactor body 2, and the installation block 3 is fixed on the lower surface of the blanking base 201. A liquid mixing device is provided inside the installation block 3, and a stirring device is provided below the installation block 3. The reactor body 2 The inner bottom is provided with a drive assembly, and the inside of the bla...

Embodiment 2

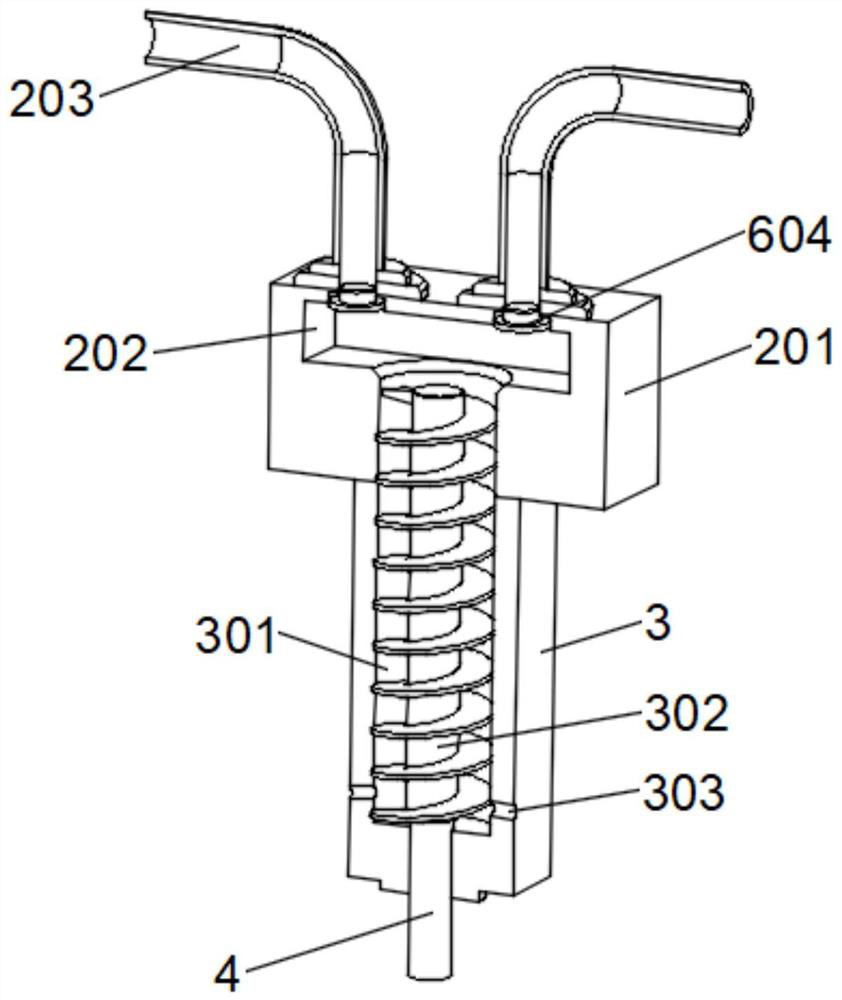

[0036] combine figure 1 , figure 2 and image 3 As shown, based on the above-mentioned embodiment 1, a mixing chamber 202 is provided above the inside of the blanking base 201, and two groups of injection pipes 203 communicated with the mixing chamber 202 are symmetrically fixed on both sides of the upper surface of the blanking base 201. The surface of the upper end is located on the rear side of the blanking base 201, and a feed pipe 204 connected to the inside of the reactor body 2 is fixed. Through the injection pipe 203, the two ingredients can be evenly introduced into the inside of the mixing chamber 202 and into the mixing hole 301. After the mixed solution inside the reactor body 2 is fully polymerized, it can be drawn out by the guide tube 204 for use.

Embodiment 3

[0038] combine figure 1 , image 3 and Figure 4 As shown, based on the above-mentioned embodiment 1 or 2, the anti-backflow component includes two groups of bottom notches 6 opened on the top wall surface of the mixing chamber 202 corresponding to the port of the injection pipe 203, and the top wall surface of the bottom notch 6 is located at the injection Both sides of the port of the tube 203 are provided with mounting holes 601 symmetrically. The top wall surface of the mounting holes 601 is fixed with telescopic rods 602 extending to the bottom notch 6. The piston 604 that is squeezed and blocked on the surface of the inner wall is equipped with a spring 603 on the outside of the telescopic rod 602, and the two ends of the spring 603 are respectively fixedly connected with the inner top wall of the installation hole 601 and the surface of the piston 604. When the ingredients are injected into 202, due to the internal pressure of the injection pipe 203, the elastic force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com