Efficient desulfurization pipeline system

A pipeline system and pipeline technology, applied in the field of desulfurization, can solve the problems of reduced efficiency of flue gas filter, affect front-end continuous production, and inability to perform flue gas desulfurization operations, etc., to achieve the effect of improving automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

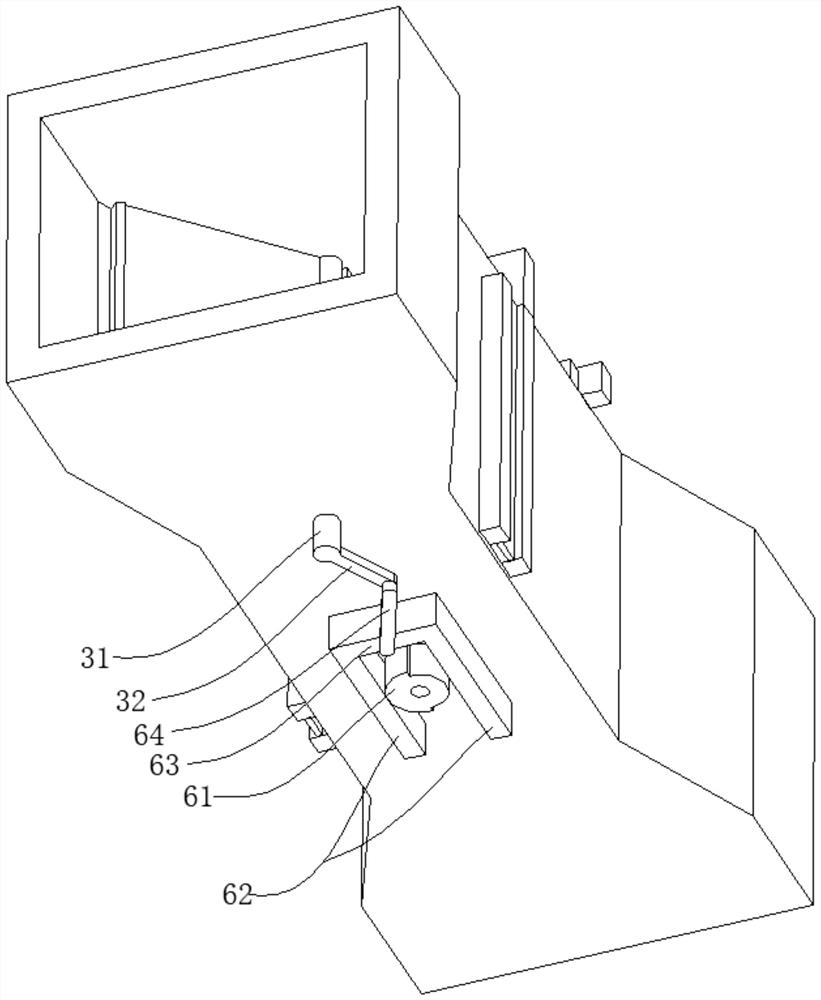

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] Such as Figure 1-3 As shown, a high-efficiency desulfurization pipeline system includes a flue gas pipeline 1 and a desulfurization tower, wherein the desulfurization tower adopts the prior art so no more details are given. The flue gas pipeline 1 is used to guide the exhaust gas into the desulfurization tower, and A filter plate set 4 is arranged in the gas pipeline 1, through which the solid particles in the exhaust gas are pre-screened, thereby improving the desulfurization efficiency in the desulfurization tower and the use efficiency of the desulfurization liquid.

[0033] The flue gas pipeline 1 includes an inlet section 11, a guide section 12, a filter section 13 and an output section 14 arranged in sequence along the exhaust gas flow direction, wherein the width of the inlet section 11 is greater than the width of the filter section 13, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com