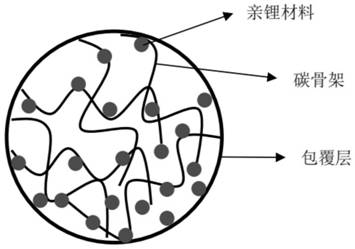

Lithium-philic carbon skeleton composite material as well as preparation method and application thereof

A composite material and carbon skeleton technology, applied in the direction of lithium batteries, structural parts, electrical components, etc., can solve the problems of not being able to effectively attract lithium metal, and achieve the effects of easy scale-up production, reducing impact, and avoiding excessive coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Mix 125g VGCF, 125g ZnO and 2250g deionized water, stir and sonicate until uniformly dispersed, then transfer the slurry with a total solid content of 10% to a sand mill, and sand mill for crushing and dispersing; use spray drying with a flow rate of 1000mL / h, temperature 160°C, air pressure 0.4Mpa, spray to obtain carbon microsphere material.

[0089] The obtained carbon microspheres were sintered, and the sintering conditions were: 5°C / min from room temperature to 300°C, holding for 2 hours, 2°C / min to 800°C, holding for 3 hours, and finally cooling down to room temperature to obtain the precursor material.

[0090] Next, in-situ liquid-phase coating is carried out on the precursor material. Dissolve 2.6g tris (trishydroxymethylaminomethane) in 1000ml deionized water, then add 100g precursor material to the above solution, and disperse evenly after magnetic stirring Add 10g of dopamine hydrochloride to the mixed solution for coating, the coating time is 24h, and the ...

Embodiment 2

[0094] Mix 125g VGCF, 125g ZnO and 2250g deionized water, stir and sonicate until uniformly dispersed, then transfer the slurry with a total solid content of 10% to a sand mill, and sand mill for crushing and dispersing; use spray drying with a flow rate of 1000mL / h, temperature 160°C, air pressure 0.4Mpa, spray to obtain carbon microsphere material.

[0095] Sinter the obtained carbon microspheres, sintering conditions: 5°C / min from room temperature to 300°C, heat preservation for 2 hours, 2°C / min temperature rise to 800°C, heat preservation for 3 hours, and finally cool down to room temperature to obtain a lithium-philic carbon skeleton composite material .

[0096] In the resulting lithiophilic carbon framework composite, the specific surface area is 167m 2 / g; tap density is 0.3g / cm 3 . Such as figure 2 As shown, the obtained lithium-philic carbon skeleton composite material has no coating layer and is only a spherical structure, and the structure contains lithium-ph...

Embodiment 3

[0098] Mix 75g VGCF, 50g conductive graphene, 100g nano-Ag powder, 25g ZnO and 2250g deionized water, stir and sonicate until uniformly dispersed, transfer the slurry with a total solid content of 10% to a sand mill, and perform the same as other steps Example 1 is the same.

[0099] The structure of the obtained lithium-philic carbon framework composite is as follows: image 3 As shown, it has a two-layer structure, the cladding layer is the outermost layer, covering the three-dimensional network structure, and the lithium-friendly material is located in the through hole in the three-dimensional network structure. Provide more space. In the obtained lithium-philic carbon framework composite: the specific surface area is 52m 2 / g; tap density is 0.3g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com