Oil pipe blanking plug for operation under pressure

A technology of tubing plug and pressure operation, which is applied in wellbore/well components, sealing/package, earthwork drilling and production, etc. It can solve the problems of early setting, poor setting, time-consuming and labor-consuming, etc., to avoid The plug is stuck, the reliability of setting is high, and the effect of ensuring the quality of setting is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

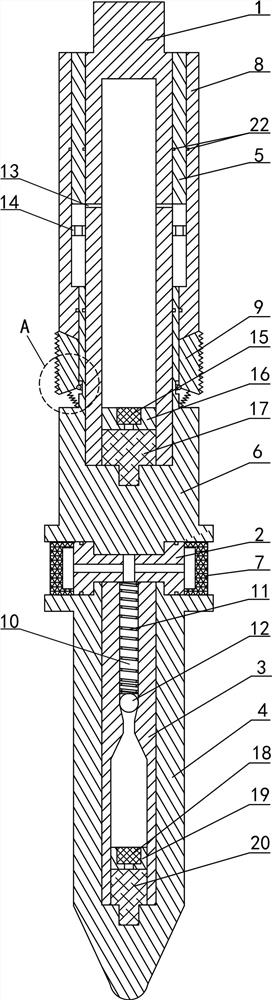

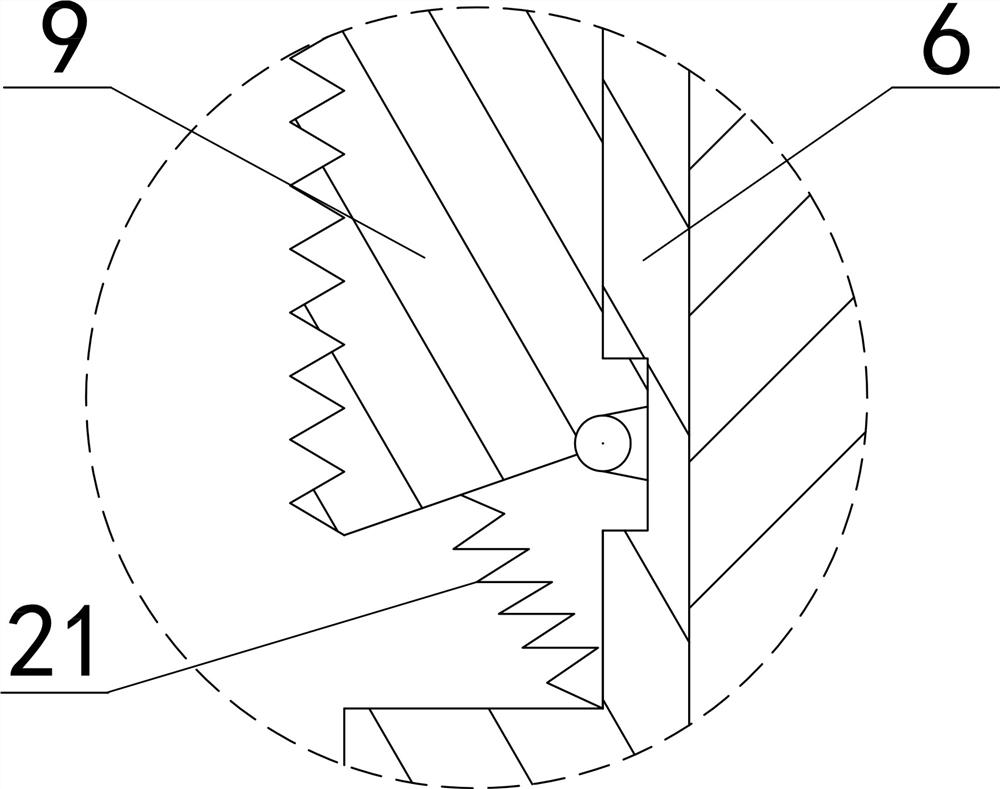

[0028] Such as figure 1 and figure 2 As shown, a oil pipe plug for working under pressure in this embodiment includes a mandrel, a fixed cylinder 5, a transition cylinder 6, a rubber cylinder 7, a working cylinder 8, slips 9, a pump body, a one-way valve and a processor , the mandrel includes an upper joint 1, a connecting block 2, a support block 3 and a lower joint 4, the fixed cylinder 5 is sleeved on the upper part of the upper joint 1, the lower end of the upper joint 1 is connected with the upper end of the transition cylinder 6, and the lower end of the transition cylinder 6 It is connected with the connection block 2, the connection block 2 is connected with the lower joint 4, the support block 3 is set in the lower joint 4, the one-way valve is set in the support block 3, the rubber cartridge 7 is installed on the connection block 2, and the rubber cartridge 7 is subjected to Extrusion of the shoulder of the transition cylinder 6 and the lower joint 4; the connectin...

Embodiment 2

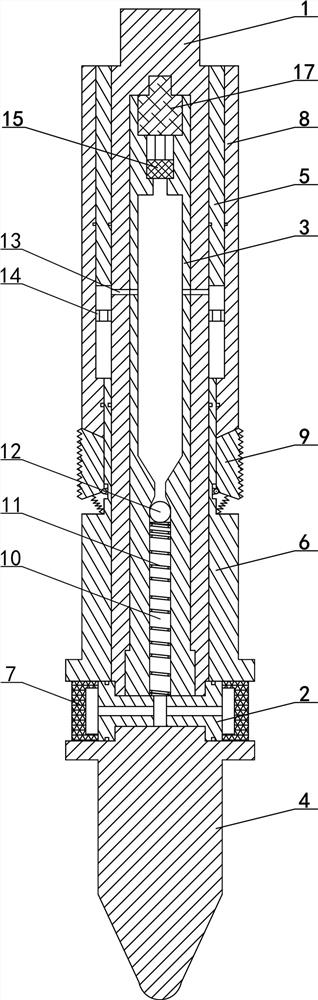

[0038] Such as image 3 As shown, the oil pipe plug for working under pressure in this embodiment is similar in structure to the oil pipe plug in Embodiment 1, the difference is that only one pump body of the oil pipe plug in this embodiment is provided, which is the first pump body 15; the processor is also only provided with one, which is the first processor 17; the mandrel includes an upper joint 1, a connecting block 2, a support block 3 and a lower joint 4, and the upper joint 1 is connected with the upper end of the connecting block 2, and the connecting block 2 The lower end is connected with the lower joint 4, the support block 3 is set in the upper joint 1; the one-way valve is set in the support block 3, the rubber tube 7 is installed on the connection block 2, and the two ends of the connection block 2 are respectively connected with the one-way valve. The small hole that the valve communicates with the rubber cartridge 7. The first pump body 15 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com