Goaf bottom edge construction drilling method and device

A bottom edge, drilling device technology, applied in the directions of safety devices, support devices, drill pipes, etc., can solve the problems of safety hazards in goafs, violent soil vibrations, and mine cave collapses, reducing vibration damage, reducing Equipment cost and the effect of reducing mine collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

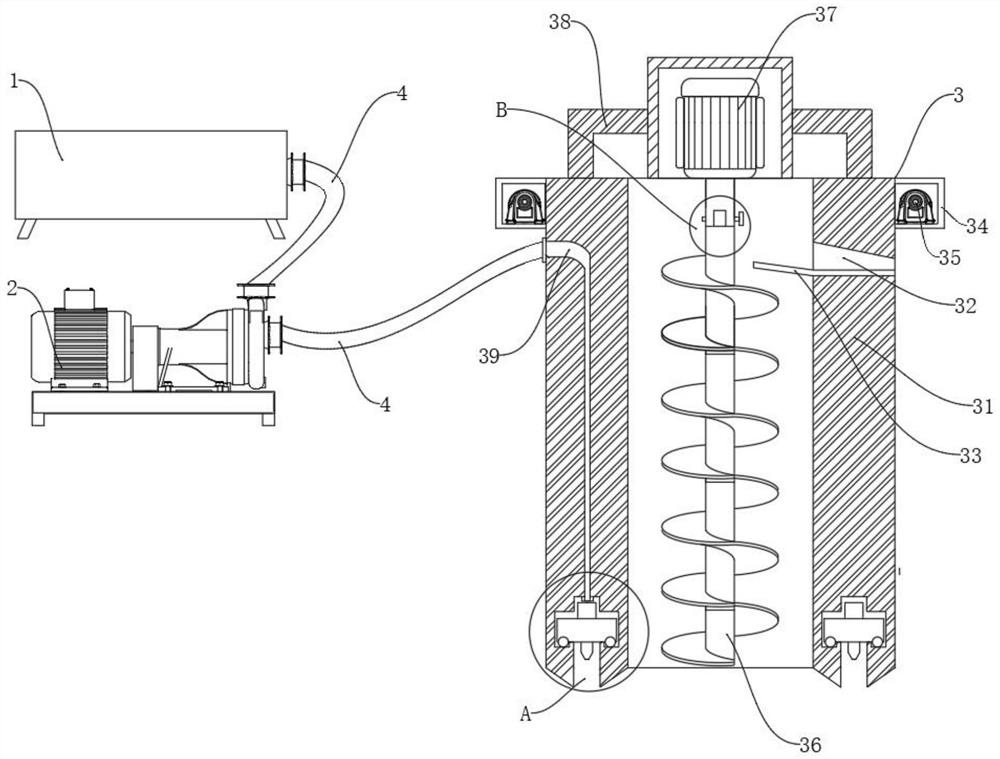

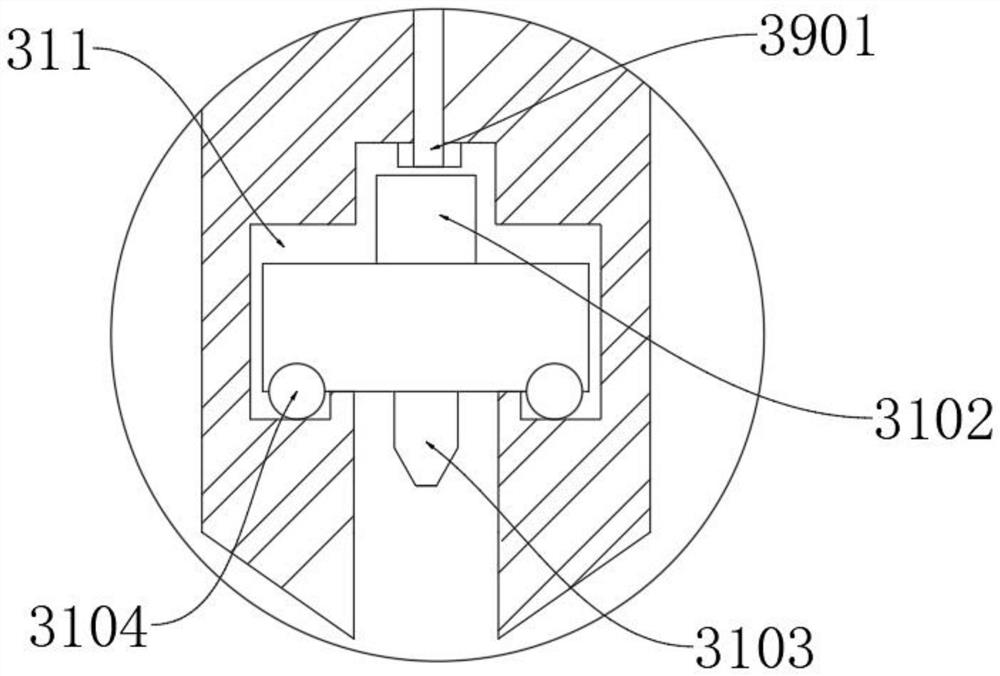

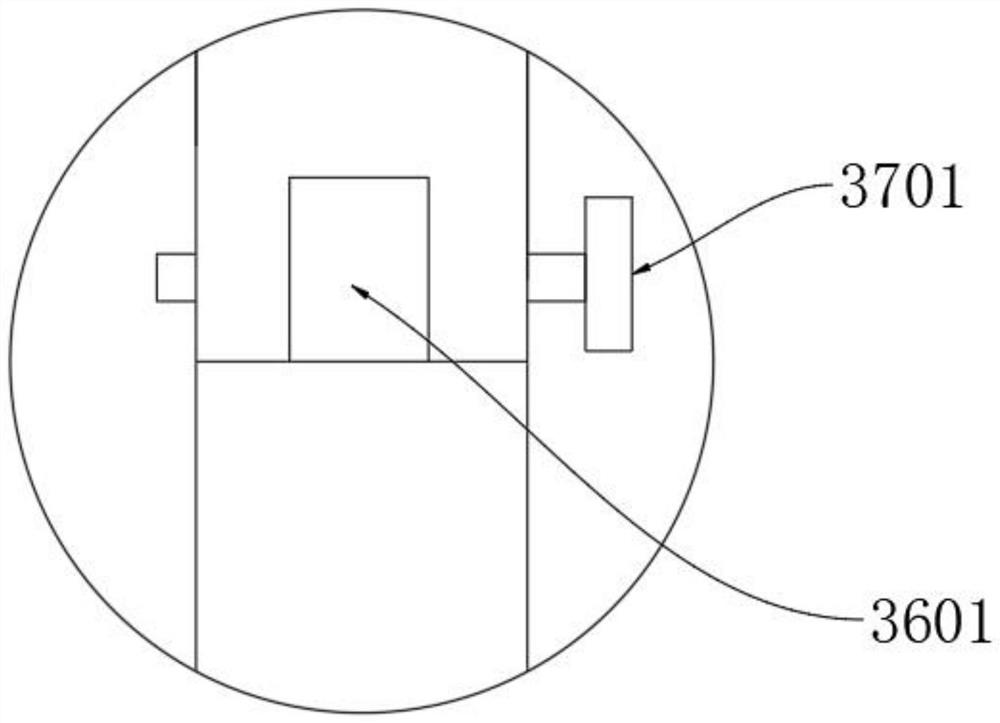

[0032] see figure 1 - Figure 5 , in the illustration: this embodiment is a preferred implementation of this technical solution, a method of drilling at the bottom edge of a goaf, comprising the following steps:

[0033] Step 1: Construct a model. Through the combination of acoustic wave scanning technology and BIM technology, build a multi-layer space visualization model inside the goaf, generate sound waves outward through the sound wave generator, and record the direction and time of sound wave return by receiving the sound wave return , send the information to the processor, and calculate the sound wave transmission distance d through the processor, d=(sound wave propagation speed V*time S) / 2, construct the gob model by combining the vector d and BIM technology, the same method , to construct the spatial model of the lower mined-out area;

[0034] Step 2, sampling analysis, select the soil composition analysis of each area at the bottom edge of the goaf, analyze the sudd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com