Preparation method and application of nickel/iron-nickel hydroxide-nickel sulfide heterojunction oxygen evolution catalytic electrode

A hydroxide and catalytic electrode technology, which is applied in the field of electrochemistry, can solve the problems of powdery catalyst shedding, poor electrode wettability, and increased use costs, and achieve low preparation costs, lower adsorption energy barriers, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0035] Step 1. Cut the nickel sheet into 10mm*20mm*0.1mm sheet, and ultrasonically clean it in acetone, ethanol, and deionized water for 20 minutes;

[0036] Step 2, put 2g of sulfur on the bottom of the ceramic ark with a lid, put the Ni sheet treated in step 1 on the top of the ceramic ark, put the lid on and put it in the tube furnace, and the tube furnace heats up to 500°C at 2°C / min Keep warm for 1h;

[0037] Step 3, put the sample processed in step 2 into 5mol L -1 It is used as anode in KOH electrolyte, with nickel sheet as cathode, and 300mA cm -2 The current density was anodized for 5 hours. After the treatment, the sample was washed with deionized water and dried to obtain a nickel hydroxide@nickel sulfide heterojunction oxygen evolution catalytic electrode.

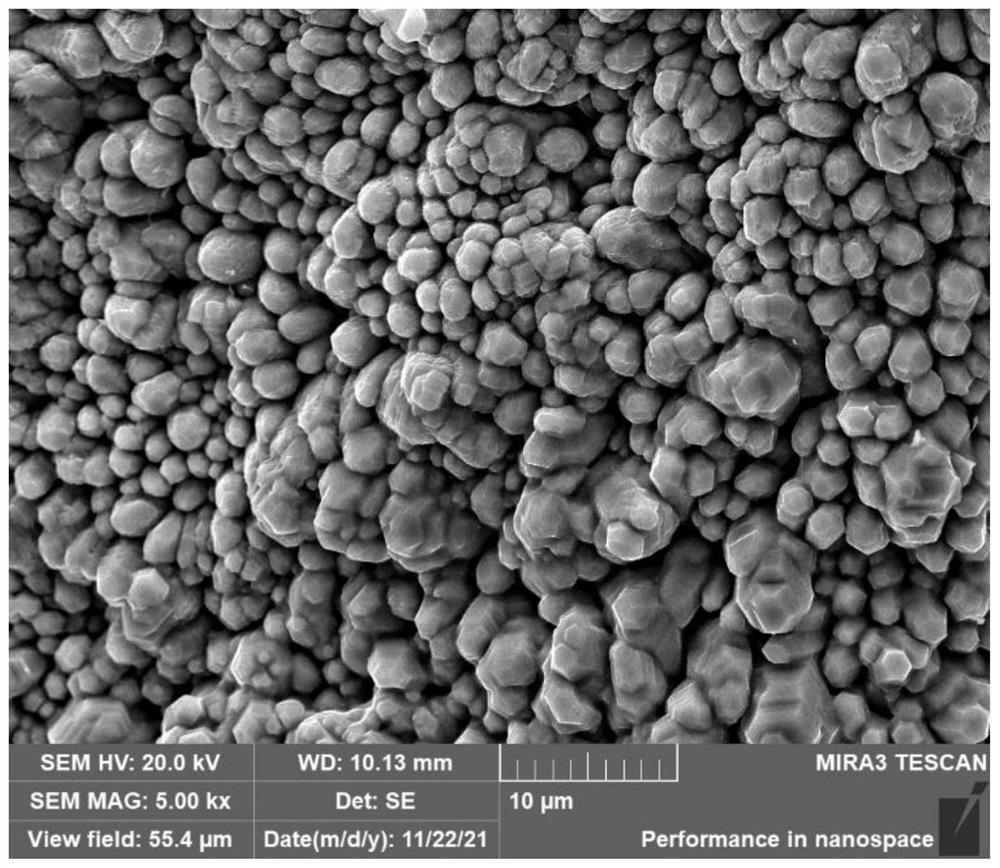

[0038] The microscopic appearance of the electrode is as figure 1 As shown, it can be seen that the microscopic morphology of the electrode is a ball-and-stick array. This structure can effectively increase ...

Embodiment example 2

[0040] Step 1: Cut foamed nickel (nickel-iron molar ratio is 5:5) iron into 10mm*20mm*0.1mm sheet, and ultrasonically clean them in acetone, ethanol, and deionized water for 30 minutes;

[0041]Step 2, put 2g of sulfur on the bottom of the ceramic ark with a cover, put the foamed ferronickel treated in step 1 on the top of the ceramic ark, put the lid on and put it in the tube furnace, and the tube furnace heats up to 410 °C at 1 °C / min Keep warm for 30 minutes;

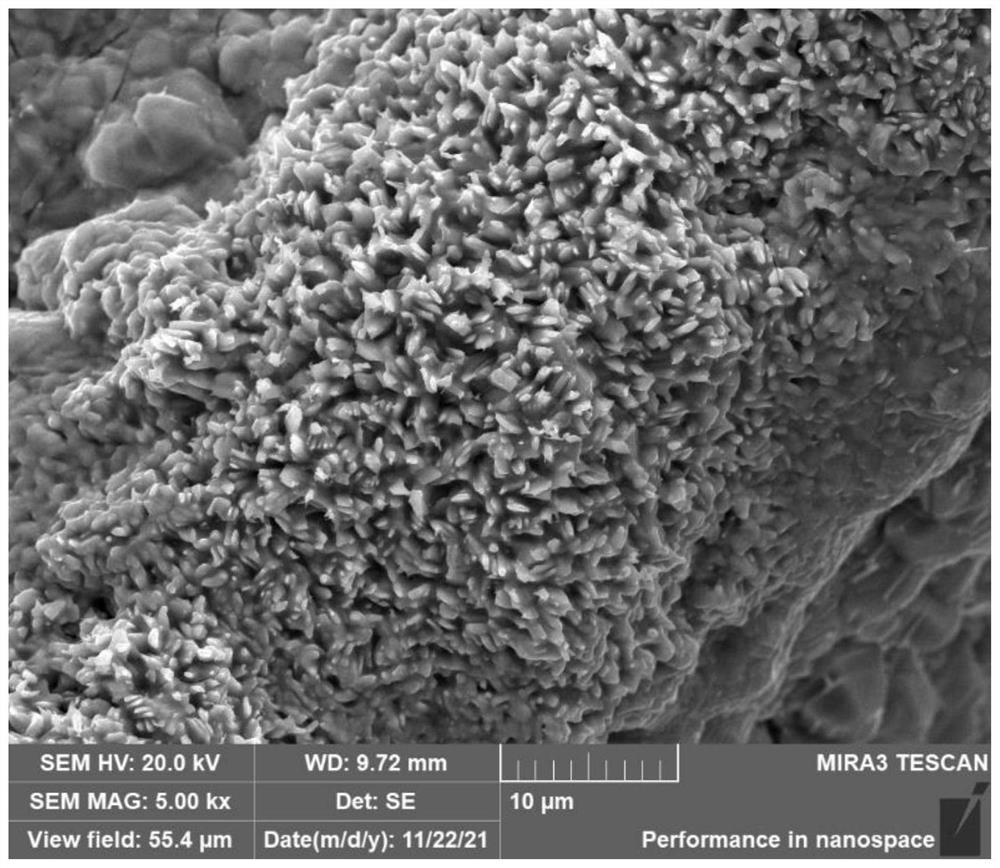

[0042] Step 3, put the sample processed in step 2 into 3mol L -1 KOH electrolyte is used as an anode, nickel sheet is used as cathode, and a constant cell voltage of 3V is applied for anodic oxidation treatment for 10 hours. After the treatment, the sample is washed with deionized water and dried to obtain nickel hydroxide@nickel trisulfide heterogeneous Condensation oxygen catalytic electrode. The microscopic appearance of the electrode is as figure 2 As shown, it can be seen that the microscopic morphology of t...

Embodiment example 3

[0044] Step 1: Cut the foamed nickel-iron (nickel-iron molar ratio is 7:3) into 10mm*20mm*0.1mm sheets, and ultrasonically clean them in acetone, ethanol, and deionized water for 30 minutes;

[0045] Step 2, put 2g of sulfur on the bottom of the alumina crucible, place the ferronickel foam treated in step 1 on the top of the alumina crucible, press a piece of alumina on it, and put them together in a resistance furnace. The temperature of the tube furnace is 3°C / raise the temperature to 450°C for 40 minutes;

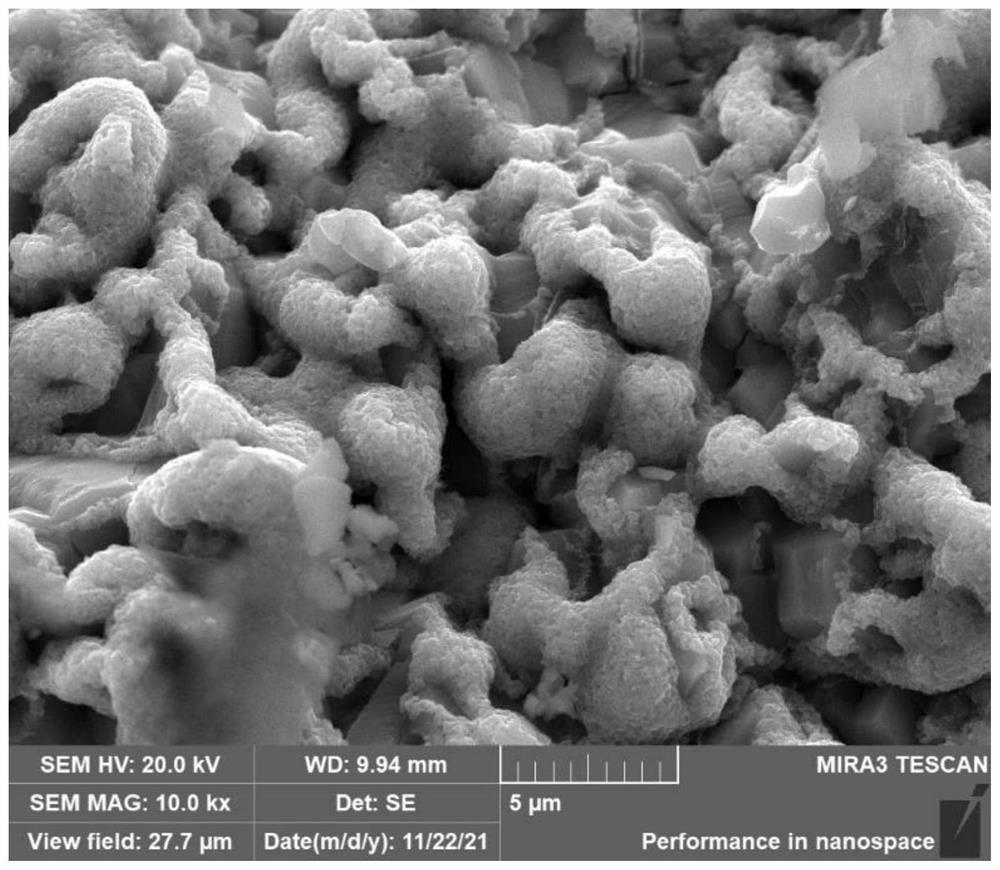

[0046] Step 3, put the sample processed in step 2 into 1mol L -1 It is used as anode in KOH electrolyte, and nickel sheet is used as cathode, and 500mA cm is applied -2 The current density was anodized for 20 hours. After the treatment, the sample was washed with deionized water and dried to obtain a snail-shaped nickel hydroxide@nickel trisulfide heterojunction oxygen evolution catalytic electrode. The microscopic appearance of the electrode is as image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com