Process method for producing ground sesameseed oil by water extraction method

A technology of small grinding sesame oil and production process, which is applied in the direction of fat production, fat oil/fat refining, etc., which can solve the problems of difficult expansion of scale, increase of production capacity, long operation time, cumbersome steps, etc., and is conducive to mechanization and standardization, production capacity expansion, Effect of reducing fragrance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

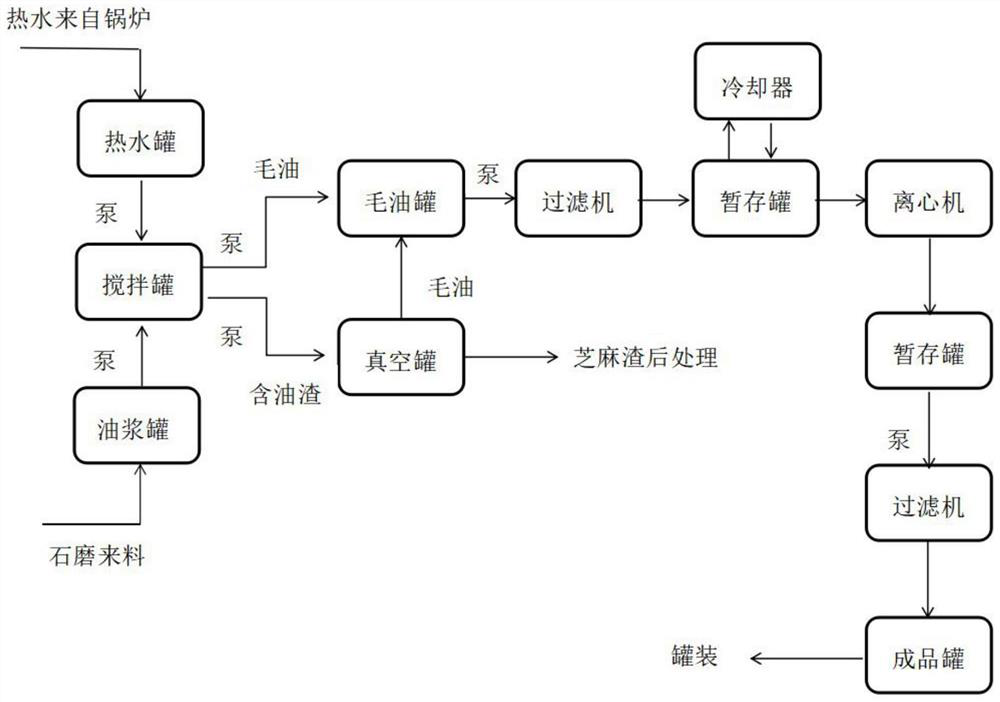

[0047]The sesame pulp obtained through previous grinding is stored in the oil slurry tank. The hot water is heated to 100°C by the boiler and sent into the hot water tank. Through the operation of the control box, the sesame pulp and hot water added to the mixing tank are respectively set. Keep the ratio of water and sesame pulp at 0.8, and open the delivery pump and valve at the same time. Through the real-time calculation of the weight of the load cell, the sesame pulp and water enter the mixing tank at the same time, and turn on the stirring paddle to stir. After the feeding is completed The inlet valve is closed. Turn on the two stirring paddles to start stirring at a faster speed, and stir the paddles at a speed of 75r / min for 20min. Reduce the speed of the stirring paddle, and stir for 60 min at a speed of 10 r / min. After the stirring is completed, stop stirring. The upper layer of crude oil is pumped into the crude oil storage tank through the oil pump, and the lower l...

Embodiment 2

[0050] The sesame pulp obtained through pre-refining is stored in the oil slurry tank, and the hot water is heated to 95°C by the boiler, and then pumped into the hot water tank. Through the operation of the control box, the sesame pulp and hot water added to the mixing tank are respectively set. Keep the ratio of water and sesame pulp at 0.8, turn on the delivery pump and valve, and calculate the quality through the real-time calculation of the load cell, first put the sesame pulp into the mixing tank, then start the stirring, and then add water, after the feeding is completed The feed inlet valve was closed, and the two stirring paddles started to reversely stir at a faster speed, and the stirring paddles stirred at 70r / min for 30min. Reduce the speed of the stirring paddle, stir at a speed of 15r / min for 80min, and stop stirring after the stirring is completed. The upper layer of crude oil is pumped into the crude oil storage tank through the oil pump, and the lower layer o...

Embodiment 3

[0053] The sesame pulp obtained through pre-refining is stored in the oil slurry tank, and the hot water is heated to 90°C by the boiler, and then pumped into the hot water tank. Through the operation of the control box, the sesame pulp and hot water added to the mixing tank are respectively set. to maintain the ratio of water and sesame pulp at 0.8, open the delivery pump and valve, and calculate the quality through the real-time calculation of the load cell, first send the water into the mixing tank, and then send the sesame pulp into the mixing tank for further After the material is finished, the feed inlet valve is closed, and the two stirring paddles start to reversely stir at a relatively fast speed, and the stirring paddles are stirred at 60r / min for 40min. Reduce the speed of the stirring paddle, and stir for 100 min at a speed of 8 r / min. After the stirring is completed, stop stirring. The upper layer of crude oil is pumped into the crude oil storage tank through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com