New energy electric vehicle multipurpose functional liquid and preparation method and application thereof

A technology for electric vehicles and functional fluids, applied in chemical instruments and methods, lubricating compositions, materials for heat exchange, etc., can solve the problems of slow cooling rate inside the battery, unsuitable cooling system, uneven heat distribution, etc. Outstanding oxidizing ability, excellent anti-rust and anti-corrosion properties, excellent electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The composition of raw materials for preparing multi-purpose functional liquid is as follows:

[0050]

[0051]

[0052] The preparation method of embodiment 1 is:

[0053] 1. Add the base oil diester into the blending kettle and heat it to 60-80°C.

[0054] 2. Add rubber anti-aging agent 264, maintain the blending temperature of 60-80 ℃ and stir for 30 minutes.

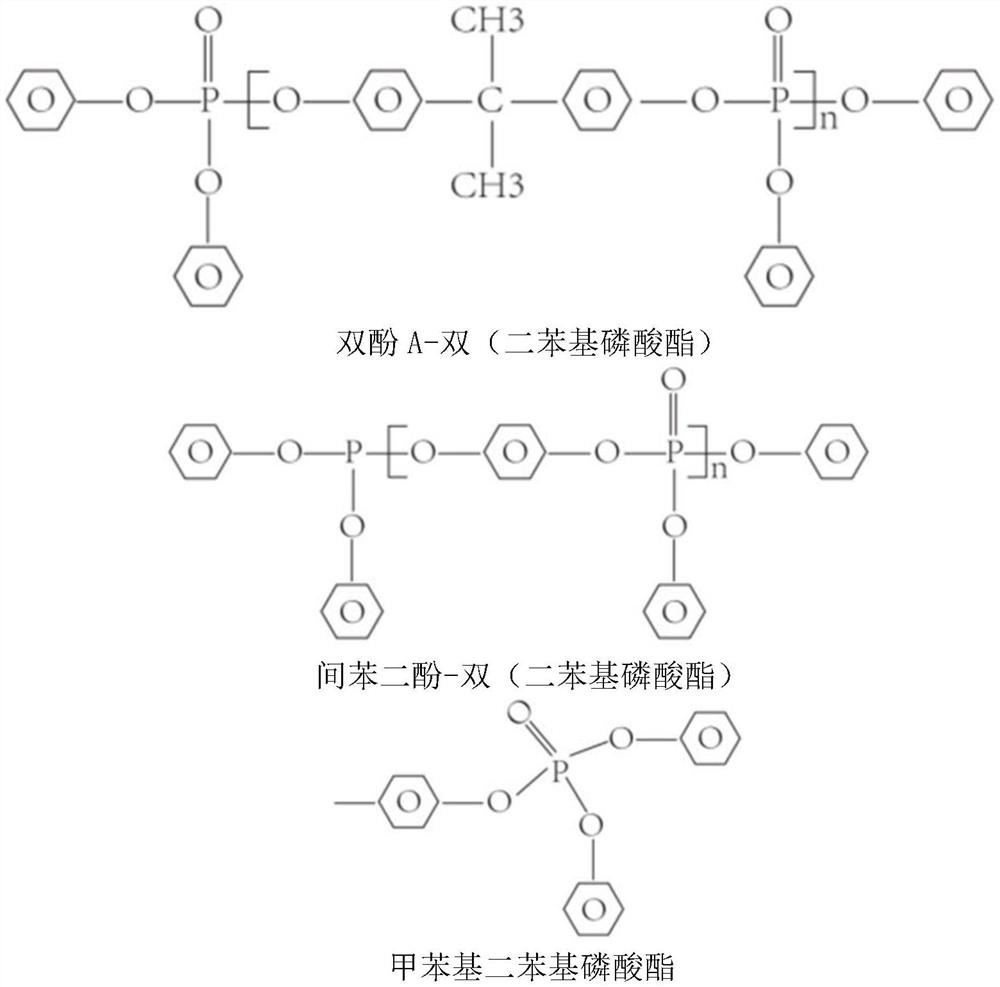

[0055] 3. Cool down to 30-50°C, add viscosity index improver: polymethacrylate, detergent and dispersant: polyisobutylene succinimide, antioxidant: alkyl diphenol / alkyl diphenylamine, extreme pressure Anti-wear agent: alkylated phosphate, flame retardant: bisphenol A-bis(diphenyl phosphate), seal compatibility improver: oil-soluble polyalkylene glycol, friction modifier: polyester, anti-corrosion Anti-rust and rare metal protection agent: N-acyl sarcosine, maintain the tempering temperature of 30-50 ℃ and stir for 30 minutes.

[0056] 4. Add base oil polyalphaolefin, add demulsifier LZ5957 and defoame...

Embodiment 2

[0058] The composition of raw materials for preparing multi-purpose functional liquid is as follows:

[0059]

[0060] The preparation method of embodiment 2 is:

[0061] 1. Add the base oil diester into the blending kettle and heat it to 60-80°C.

[0062] 2. Add rubber anti-aging agent 264, maintain the blending temperature of 60-80 ℃ and stir for 30 minutes.

[0063] 3. Cool down to 30-50°C, add viscosity index improver: polymethacrylate, detergent and dispersant: polyisobutylene succinimide, antioxidant: alkyl diphenol / alkyl diphenylamine, extreme pressure Anti-wear agent: alkylated phosphate, flame retardant: bisphenol A-bis(diphenyl phosphate), seal compatibility improver: oil-soluble polyalkylene glycol, friction modifier: polyester, anti-corrosion Anti-rust and rare metal protection agent: N-acyl sarcosine, maintain the tempering temperature of 30-50 ℃ and stir for 30 minutes.

[0064] 4. Add base oil polyalphaolefin, add demulsifier LZ5957 and defoamer LZ889D in ...

Embodiment 3

[0066] The composition of raw materials for preparing multi-purpose functional liquid is as follows:

[0067]

[0068] The preparation method of embodiment 3 is:

[0069] 1. Add the base oil diester into the blending kettle and heat it to 60-80°C.

[0070] 2. Add rubber anti-aging agent 264, maintain the blending temperature of 60-80 ℃ and stir for 30 minutes.

[0071] 3. Cool down to 30-50°C, add viscosity index improver: polymethacrylate, detergent and dispersant: polyisobutylene succinimide, antioxidant: alkyl diphenol / alkyl diphenylamine, extreme pressure Anti-wear agent: alkylated phosphate, flame retardant: bisphenol A-bis(diphenyl phosphate), seal compatibility improver: oil-soluble polyalkylene glycol, friction modifier: polyester, anti-corrosion Anti-rust and rare metal protection agent: N-acyl sarcosine, maintain the tempering temperature of 30-50 ℃ and stir for 30 minutes.

[0072] 4. Add base oil polyalphaolefin, add demulsifier LZ5957 and defoamer LZ889D in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com