Special mosquito-repellent end sealing adhesive for paper diapers and preparation process of mosquito-repellent end sealing adhesive

A technology for diapers and mosquito repellent, which is applied in the field of special mosquito repellent end sealant for diapers and its preparation technology, can solve the problems of lack of mosquito repellent function and the like, and achieve the effects of good opening time and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

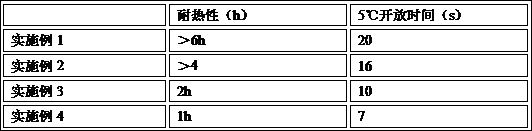

Examples

Embodiment 1

[0031] A special mosquito repellent end sealant for paper diapers, the components are as follows:

[0032] 72g ethylene-vinyl acetate copolymer, 15g modified polyalphaolefin, 25g tackifying resin, 0.05g mosquito repellant, 0.5g antioxidant, 0.15g calcium carbonate, 2g microcrystalline paraffin, 0.4g polyethylene glycol 200 , 0.7g dioctyl phthalate.

[0033] The preparation method of the special mosquito repellent end sealant for paper diapers is as follows: add all the above raw materials into the mixer and mix them, then heat up to 50°C while stirring at a stirring speed of 80 rpm, keep warm at 50°C for 3 hours, and continue stirring Raise the temperature to 160°C while heating, keep the temperature at 160°C for 3 hours, and cool to 40°C to obtain it.

[0034] Wherein, the mosquito repellent is peppermint oil, and the tackifying resin is hydrogenated C5 petroleum resin. The preparation method of described modified polyalpha-olefin is as follows:

[0035] Add 100kg of APAO ...

Embodiment 2

[0037] A special mosquito repellent end sealant for paper diapers, the components are as follows:

[0038] 73g ethylene-vinyl acetate copolymer, 15.5g modified polyalphaolefin, 25.2g tackifying resin, 0.05g mosquito repellent, 0.6g antioxidant, 0.15g calcium carbonate, 2g microcrystalline paraffin, 0.4g polyethylene glycol Alcohol 200, 0.7 g dioctyl phthalate.

[0039] The preparation method of the special mosquito repellent end sealant for diapers is as follows: add all the above-mentioned raw materials into the mixer, then heat up to 50°C while stirring at a stirring speed of 80 rpm, keep warm at 50°C for 3 hours, and continue stirring while Heating to 162°C, keeping the temperature at 162°C for 3h, and cooling to 40°C to obtain the product.

[0040] Wherein, the mosquito repellent is peppermint oil, and the tackifying resin is hydrogenated C5 petroleum resin. The preparation method of described modified polyalpha-olefin is as follows:

[0041] Add 100kg of APAO to the re...

Embodiment 3

[0043] A special mosquito repellent end sealant for paper diapers, the components are as follows:

[0044] 71g ethylene-vinyl acetate copolymer, 14g modified polyalphaolefin, 26g tackifying resin, 0.05g mosquito repellent, 0.5g antioxidant, 0.5g calcium carbonate, 2g microcrystalline paraffin, 0.7g phthalate Octyl esters.

[0045] The preparation method of the special mosquito repellent end sealant for diapers is as follows: add all the above-mentioned raw materials into the mixer, then heat up to 50°C while stirring at a stirring speed of 80 rpm, keep warm at 50°C for 3 hours, and continue stirring while Heating up to 160°C, keeping the temperature at 160°C for 3h, cooling to 40°C to obtain the product. Wherein, the mosquito repellent is peppermint oil, and the tackifying resin is hydrogenated C5 petroleum resin. The preparation method of the modified polyα-olefin is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com